Crack Patterns Resemble Fluid Turbulence

Physicists have found a surprising link between fluid turbulence and the complex surfaces created during the fracture of a solid material. Mathematical analysis of fractured surfaces in materials with widely different properties confirms a theoretical conjecture made some 20 years ago about the fracture process on microscopic scales. The work could lead to new ways of determining a material’s mechanical properties based on scans of its fracture surfaces.

The fracture of a brick or piece of metal creates rough surfaces with so-called fractal or self-similar structures. Small portions of the surface, if magnified, look identical to larger portions. This pattern of self-similarity is also universal, arising during the fracture of essentially any solid material.

Researchers understand the origin of this universality, at least on long length scales, where fracture patterns reflect the universal way that a crack propagates as it navigates around material inhomogeneities. On small scales, however, researchers don’t know why the resulting structures don’t vary significantly from one material to another. Jean-Philippe Bouchaud of Capital Fund Management in Paris and his colleagues now argue that the character of fractured surfaces on small scales reflects the way microscopic cracks grow and then rapidly coalesce in the material. This process happens in an identical way even in different materials, in much the same way that all turbulent fluids behave identically.

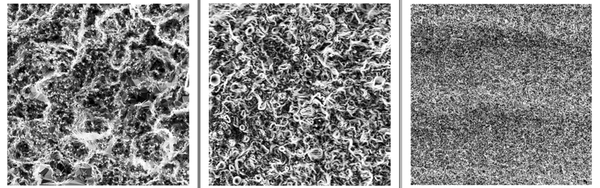

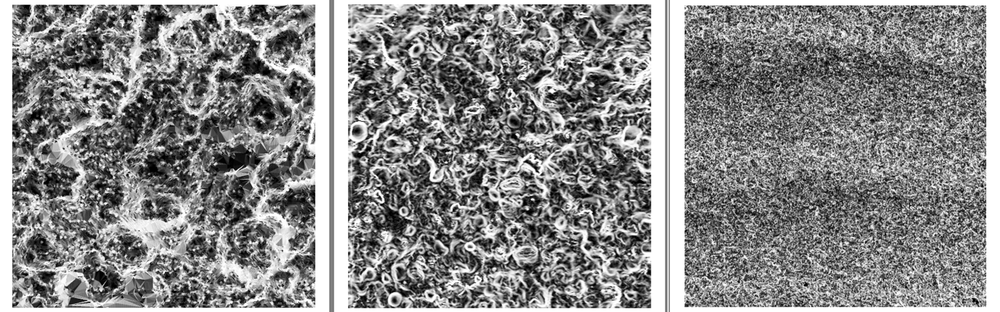

The researchers fractured three very different materials—aluminum, mortar, and ceramic. Using various imaging methods such as electron microscopy, they created maps of the irregular fracture surfaces and analyzed them statistically. This raw data showed that, over short distances, the surfaces didn’t go up and down in a gentle, continuous way, but were instead characterized by a preponderance of steep cliffs.

The team then analyzed this raw data further, looking at how the steepest of these cliffs were distributed spatially over the surface. The analysis showed that for each material, the cliffs were nested in a highly organized pattern known as a multifractal, which is a mixture of many fractals. A fractal pattern is always characterized by a number called its fractal dimension; a multifractal is a mathematical combination of fractals with a range of fractal dimensions.

Observing multifractal properties is significant, the researchers suggest, because multifractals have previously been seen mainly in two other settings—fluid turbulence and financial time series. Further mathematical analysis of the cliff distribution showed that at least three distinct numbers characterizing the pattern were virtually identical for the three different materials, suggesting some deep uniformity in the fracture process that creates these cliffs.

This universality may point to a process, suggested by physicists almost 20 years ago [1], in which fracture proceeds in a material through the creation of multiple microcracks, or “damage cavities,” which recombine and coalesce rapidly as the crack propagates. “In the process,” says Bouchaud, “voids get created and expand, deforming the material and creating more voids. Then when they coalesce, they leave behind these ‘steep cliffs’, or ‘scars’.” This process dissipates energy in the material and seems to happen the same way in every material. In fluid turbulence, instead of voids creating voids, it’s large-scale eddies that produce eddies at smaller and smaller scales, until the smallest ones simply generate heat (dissipate energy). This turbulent “cascade” is similar in all fluids.

Other physicists are surprised by the strength of the apparent link to turbulence. “Some 20 years ago we had thought about an analogy between turbulence and rough surfaces on purely formal grounds,” says Joachim Krug of the University of Cologne in Germany. “But I wouldn’t have expected turbulence concepts to become useful for understanding the surfaces of real materials. I’m really intrigued.”

Aside from this fundamental understanding of fracture, Bouchaud and colleagues believe this work may also lead to new ways to characterize fractured surfaces. By looking at the patterns of steep cliffs, it should be possible to estimate a material’s ability to avoid fracturing under stress (toughness), says team member Stéphane Vernède of the Pierre and Marie Curie University in Paris. This procedure might be useful in the aftermath of air crashes or other accidents when investigators search for the root of a material failure.

This research is published in Physical Review Letters.

–Mark Buchanan

Mark Buchanan is a freelance science writer who splits his time between Abergavenny, UK, and Notre Dame de Courson, France.

References

- K. Ravi-Chandar and B. Yang, “On the Role of Microcracks in the Dynamic Fracture of Brittle Materials,” J. Mech. Phys. Solids 45, 535 (1997)