Neutron Vision

Superman can’t see through lead with his x-ray vision, but if he could see with neutrons he’d do better. Neutrons can penetrate dense materials, and in the 2 June PRL, researchers describe a simple, 3-D imaging technique that does not require a high-quality neutron beam. The technique could prove especially useful for studying the internal structure of magnetic materials, the researchers say.

Neutrons have wave as well as particle properties [see Focus story from 12 May], so they can be controlled with analogs of standard optical techniques. Passing neutrons through a pinhole creates a tightly collimated beam, while refraction from a suitable crystal–separating wavelengths a bit like a prism–can yield neutrons of a single energy or wavelength. But in both cases, winnowing out unwanted neutrons severely reduces the intensity of the beam, which has made neutron imaging by such methods time-consuming and complex.

Franz Pfeiffer and his colleagues at the Paul Scherrer Institute in Villigen, Switzerland, devised an imaging system that uses a series gratings, opaque screens with many narrow, parallel slits in them. Neutrons from a 2-centimeter-wide beam first hit a coarse grating, which creates a series of bright neutron “lines.” Each neutron line acts independently as a single “coherent” source of waves, like light from a pinhole used in classic optics experiments, because the slits are widely spaced (several millimeters apart). Using many such “sources,” instead of just one, provides 100 times the neutron intensity of other techniques.

Next the wave-like neutrons hit a second, finer grating and create a characteristic pattern of alternating high and low neutron intensity–so-called interference fringes–on the far side. An object placed between the first and second gratings bends the path of neutrons passing through it, just as a piece of glass refracts light rays. This refraction shifts the interference pattern produced after the second grating. Neutron detectors, however, don’t have the resolution to image the interference fringes directly, or to detect tiny shifts in them.

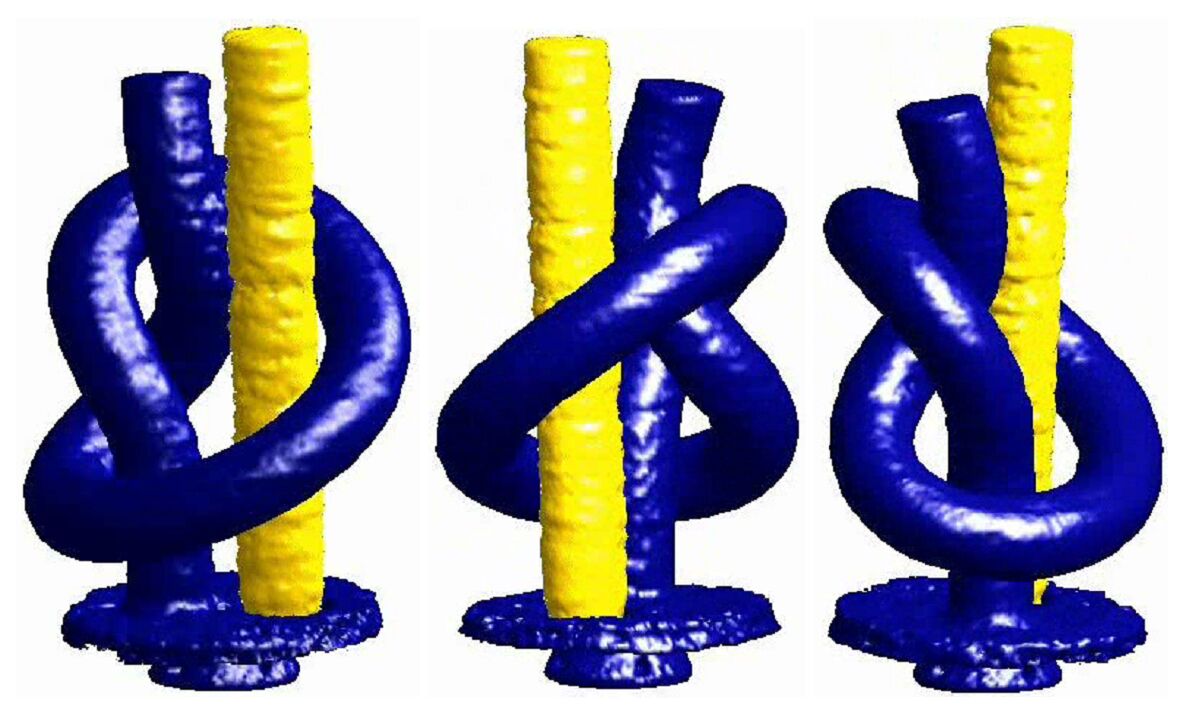

To extract information from their set-up, the Swiss team places a third grating a short distance beyond the second, with spacing chosen to match the periodicity of the fringes. They then measure the changes in neutron intensity transmitted through this third grating as it is slowly moved across the interference pattern. This trick is akin to sliding one comb in front of another–small changes in position translate into large changes in the total transmitted light. Using a two-dimensional detector array to image the shifts as the object is rotated, the researchers can mathematically generate the 3-dimensional internal structure of the object based on its ability to refract neutrons. Neutron refraction can cleanly distinguish between, say, titanium and molybdenum, even though their absorption of neutrons is similar. The technique is also insensitive to intensity variations across the neutron beam’s width, so the beam need not be ideal.

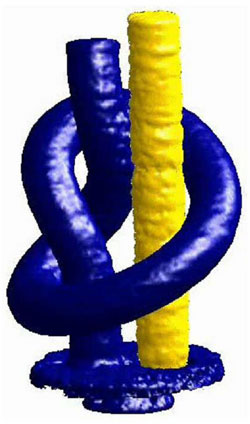

In what Pfeiffer calls a demonstration of principle, he and his colleagues created neutron profiles of 6- and 7-millimeter-wide rods of titanium, lead, molybdenum, and magnesium, including 3-D images of one “knotted” around another. Further development of the method, Pfeiffer hopes, will lead to a practical way of mapping the interiors of solids, such as the domain structure of magnetic materials, to which neutrons respond without the interference of electrostatic effects.

Muhammad Arif of the National Institute of Standards and Technology in Gaithersburg, Maryland, is impressed with the work, although he says that higher resolution will require extreme precision in making the gratings, which will be challenging. But the more efficient use of neutrons, he adds, makes this a technology worth pursuing.

–David Lindley

David Lindley is a freelance science writer in Alexandria, Virginia.