A Very Short Movie

In a hundred picoseconds, light can barely travel the width of your thumb. But a team reporting in an upcoming issue of Physical Review Letters has managed to take a snapshot in that time of the debris blasted away by a laser pulse hitting a chunk of aluminum. Researchers use such ultrashort pulses to cut tiny holes for nanostructures, and the new paper includes time-lapse movies that clear up some of the mystery surrounding the process. The images suggest that even with the shortest pulses, heating contributes to the ejection of material, and the more exotic charge effects are not entirely responsible. The results may help improve precision lithography and other nano-engineering techniques.

Using a laser like a tiny chisel to blast away, or “ablate,” atoms from a surface is an increasingly popular way to etch precision structures to form micro- and nano-machines. Femtosecond laser blasts are intensely powerful because their energy is compressed into such a short time, and they can make efficient, clean cuts. Longer pulses, by contrast, tend to melt some of the nearby material. Researchers have assumed that with a short pulse of energy there isn’t time to heat up the crystal structure. In one scenario, called Coulomb explosion, the excited electrons fly away quickly, leaving behind positively-charged ions that fly apart from repulsion rather than from heating. But ablation happens so quickly that researchers don’t completely understand how the laser energy is absorbed and how the material is ejected.

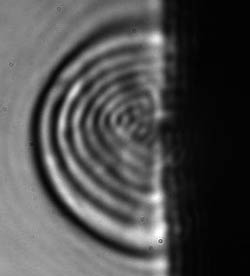

To learn more, Xiaonong Zhu and his colleagues at Nankai University in Tianjin, China, took pictures of the process starting at 100 picoseconds, faster than ever before. The team aimed 50-femtosecond laser pulses at samples of aluminum, silicon, and glass. They diverted a portion of each pulse into a second “probe” beam that shined along a variable “delay line” path and then sideways through the ejected debris. Each probe pulse produced a shadow picture of the emerging plume at a precise time following the main pulse. Learning about ablation this way is akin to watching popcorn fly through the air and then deducing how heat must have traveled through the unpopped kernels before they became airborne.

The images show a growing hemisphere of material kicked up by the ablation pulse. Between about 500 picoseconds and 3 nanoseconds, alternating dark and light arcs appear inside. Zhu and his colleagues interpret these as a diffraction pattern, a sign that for aluminum, the probe light is transmitting through a transparent, non-conducting liquid, whereas the initially liberated aluminum is an opaque, liquid metal, they say. Based on their knowledge of aluminum, the team says the transition to transparency suggests a rapid decrease in temperature and pressure, which must have followed a sudden heating by the laser pulse to a temperature of perhaps Kelvin. So they believe heating of the atoms is central to the ablation process, even with a pulse as short as 50 femtoseconds. Processes like the Coulomb explosion are not the full story.

“There is a lot of arguing [among researchers] about the physical mechanism of the material removal,” says laser scientist Michael Withford of Macquarie University in Sydney, Australia. He is impressed by the ingenuity of Zhu’s shadow movies and believes they will help resolve some of the issues. “Having that time-resolved capability where you are looking at the evolution of the droplets strikes me as quite unique.”

–Mike Wofsey