Copper, Sputter Thyself

In the coating process known as sputtering, which is used widely in research and industry, energetic ions from a plasma slam into a solid, knocking out atoms that then cover nearby surfaces. In the 30 January Physical Review Letters, researchers show that by operating a sputtering machine at voltages far beyond the manufacturer’s recommended limits, they can dramatically increase the number of ions it produces. The team theoretically describes the sudden increase in ion output they observed in this high-voltage regime. The method could provide improved corrosion-resistant coatings for aircraft parts or tiny wires for integrated circuits.

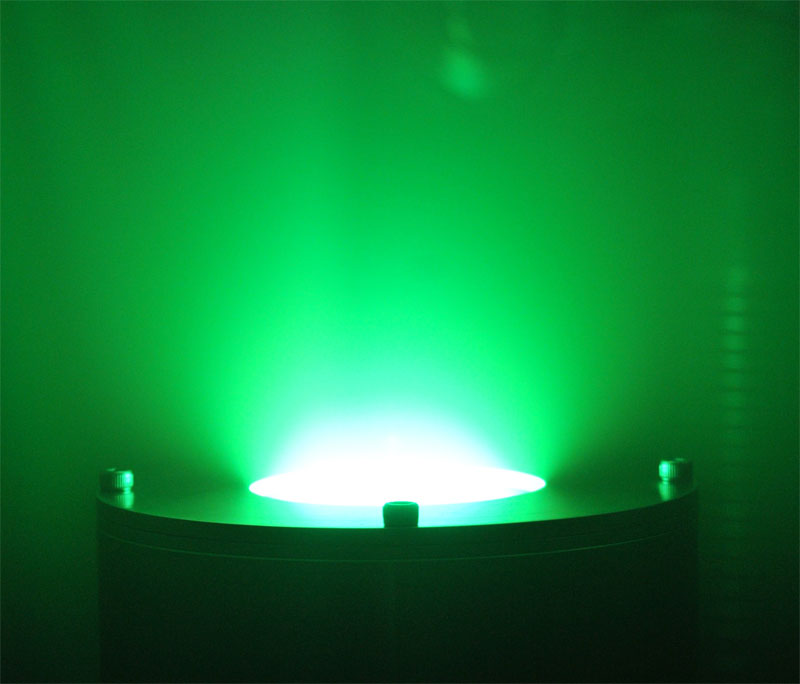

Sputtering is one of several ways to deposit thin films on a substrate like a machine tool or a semiconductor wafer. The substrate is placed, along with a “target” made of the material to be deposited, in a chamber filled with gas at low pressure. Researchers apply a voltage to the target that ionizes the gas nearby, creating a plasma discharge–a glowing haze above the target–much like the plasma in a fluorescent light bulb. Plasma ions are attracted to the target, and as each one hits, it knocks out several atoms, which fly across the chamber and coat surrounding surfaces, including the substrate.

One problem with sputtering is that the resulting coating contains microscopic voids, which can cause problems later on. To improve the film quality, some researchers have been increasing the plasma density, essentially making the “fluorescent bulb” brighter, by using very high target voltages. The denser plasma kicks up more atoms and ionizes many of them as they pass through it. And when these ions, along with neutral atoms, coat the substrate, they create a less porous film, compared with films made with neutral atoms exclusively. To avoid catastrophic heating, however, the plasma discharge must be generated in infrequent pulses a few tens of microseconds long, so the overall number of ions is modest. Joakim Andersson and André Anders of the Lawrence Berkeley National Laboratory in Berkeley, California, wanted to see what happened if they pushed the plasma even harder. “We have a sense of play,” says Anders.

“It took surprisingly little increase in voltage,” Anders recalls, before the team saw a sudden and dramatic rise in the number of ions hitting the substrate. At this high voltage (several hundred volts), which Anders jokingly calls “abusive” to the sputtering rig, there is a feedback effect, where so many atoms are dislodged from the target and ionized that many remain in the plasma and supplement it. This increased plasma then knocks out more atoms, leading to a “runaway.” Others have seen “self-sputtering” before–a regime where target atoms are dislodged by other, recycled target atoms. But no one has previously increased the current of ions hitting the substrate beyond the current in the plasma. To allow time for this process, the researchers had to keep the pulses on much longer than normal–about 400 microseconds–and avoid overheating by waiting longer between pulses.

The researchers demonstrated the role of the target atoms by removing the gas from the chamber entirely and initiating a plasma with a brief electric arc–a “puff” of plasma to get the feedback started. They also used a target made of copper, whose atoms are especially easy to dislodge. The observations fit with a simple theory that explains why increasing target voltage leads to exponentially increasing ionization of target atoms passing through the plasma. The key is that raising the voltage heats up the plasma’s electrons, which can then ionize more target atoms.

The resulting ion current available for a substrate is much higher than other researchers have produced. Ulf Helmersson of Linköping University in Sweden admits to initially having “some disbelief” that the ion current could exceed the current supplied to the target but has become convinced. The new work is “a very important contribution to understanding this kind of discharge,” says Arutiun Ehiasarian of Sheffield Hallam University in England, and could also expand the practical application of high-current pulsed sputter deposition.

–Don Monroe

Don Monroe is a freelance science writer in Murray Hill, New Jersey.

More Information

Entry from Ulf Helmersson’s sputtering blog about this paper

News release from Lawrence Berkeley National Laboratory