Electric Field from a Built-In Flex

Some materials sprout an electric field when you bend them, a phenomenon called the flexoelectric effect. In the 29 July Physical Review Letters, a team describes generating a large flexoelectric effect by growing a thin film with a “built-in flex.” They also varied the degree of flexing and therefore the strength of the electric field it generated. The effect can be surprisingly strong and may someday find uses in nanoscale sensors and actuators.

The flexoelectric effect is the trendy younger cousin of the better-known piezoelectric effect, in which certain solids develop an internal electric field when squeezed or stretched. The phenomenon has proven useful in devices from scanning tunneling microscopes to cigarette lighters, but it can only exist in 20 of the 32 crystal symmetry classes that materials scientists use to categorize solids.

Materials that generate a field from bending, on the other hand, may come from any symmetry class. Bending a crystal stretches each atomic layer by a slightly different amount, with the layer at the outer surface of the bend stretched the most. This “strain gradient” can shift some ions in the crystal enough to generate an electric field. The effect has been seen in bendy materials like liquid crystals, graphene, and even hair, but it was never noticeable enough in an ordinary solid to be useful.

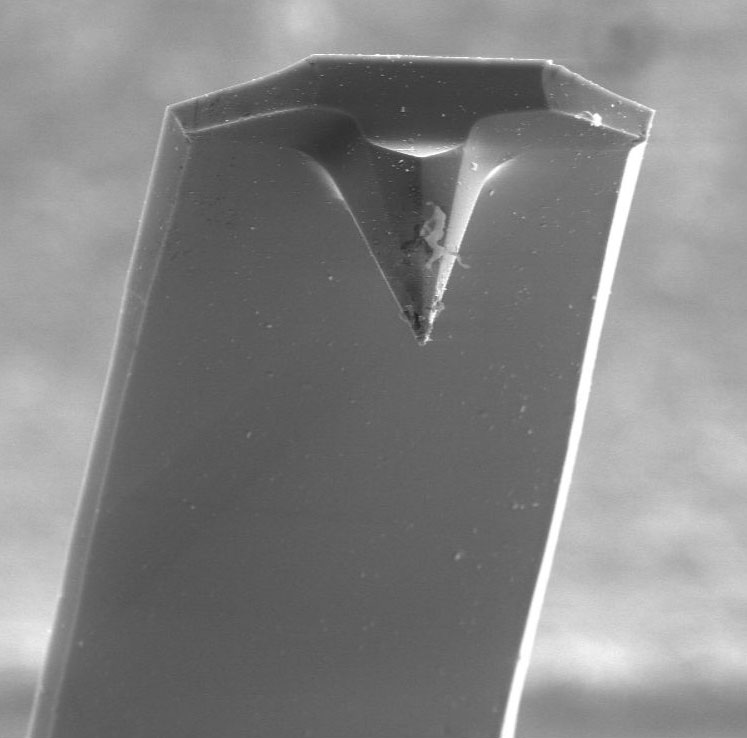

Instead of starting with a flexible material and bending it, Tae Won Noh of Seoul National University in Korea and colleagues built the strain gradient right into their crystal. The team grew thin films of holmium manganese oxide ( ), which is ferroelectric, meaning it can maintain a permanent electric field, just as a ferromagnet maintains a magnetic field.

A standard way to build a strain gradient into a film is to grow it layer-by-layer onto a surface where the atoms are spaced slightly differently from the “native” crystal of interest. The team used a sapphire surface, whose atomic spacing is 3.5 percent wider than Atoms of each successive layer that condensed from the vapor were spaced slightly closer together than the layer below, but this “relaxation” toward the natural spacing varied dramatically depending on the amount of oxygen gas in the chamber. With low oxygen, the film formed with many empty oxygen sites, which reduced its ability to “tighten up” its atomic spacing with increasing thickness. So the top layer spacing was much wider than for high-oxygen films.

Using x-ray diffraction on high-oxygen films, the team measured strain gradients that were one to ten million times larger than others had measured for macroscopic strips of similar materials that were bent. This huge strain gradient induced a large electric field via the flexoelectric effect, Noh says.

Ordinarily, the electric field inside a ferroelectric material isn’t uniform overall; the material breaks up into zones, each with a field in a specific direction. The team directly imaged these domains and showed that the flexoelectric effect was strong enough at high temperatures in the high-oxygen samples to generate a single domain in the film. But films grown under lower oxygen (and thus with lower strain gradients) had less effect on the domains and other ferroelectric properties. So controlling the oxygen level amounted to a way of “tuning” the material’s properties.

“You can use this electric field to control the physical properties of your system,” Noh says. “Nobody has used the flexoelectric effect to control those kinds of properties.” Noh says highly strained films have been around for decades, but no one looked at their flexoelectric effect before. “We’re saying to workers in the field, ‘Look at it. Pay attention to these properties.’”

The key result is that the atmospheric conditions during growth of the films affect their flexoelectricity, says Gustau Catalan of the Nanoscience and Nanotechnology Research Center (CIN2) in Barcelona, Spain. “Flexoelectricity can therefore be controlled by a careful choice of growth conditions, allowing the tuning of an important physical property,” he says. Piezoelectrics are expected to be useful in future nanoscale motors and memories, says Noh, so flexoelectric films may also be important in these devices.

–Lisa Grossman

Lisa Grossman is a freelance science writer.