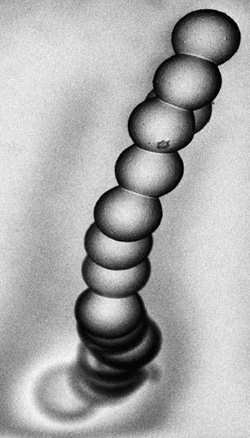

Polymer Pearl Necklaces

Like beads on a necklace, microscopic spheres made from polymers can be strung together to form new materials with many possible uses. Researchers describe these three-dimensional networks in the 7 January print issue of PRL. These new materials may someday be fine tuned for applications in optoelectronic components or magnetic media.

To a chemist, silicon can be hopelessly restrictive. Semiconductors and other inorganic crystals are the basis for electronics and other technologies, but–aside from small changes available by doping with impurities–their chemical properties are essentially fixed. Carbon-based polymers, on the other hand, have almost unlimited possibilities in the hands of a good chemist, who can modify the repeated chemical groups to suit whatever application she has in mind. Materials scientists are trying to exploit such chemically flexible, or “soft,” materials in many areas, including electronics.

Chemists Mike Barnes and Don Noid and their colleagues at the Oak Ridge National Laboratory in Tennessee developed a technique for blending solutions of two different polymers that normally avoid one another. They force the water to evaporate so quickly that the molecules can’t separate and instead clump together into microscopic spheres. Now they’ve discovered that the individual microspheres can string themselves together in the process, forming branching structures and columns. The team believes that as the water evaporates, the ends of the polymer chain molecules sticking out from the surfaces of the growing microspheres can bond one sphere to another. The result of this process is a stable, three-dimensional, chain or network structure.

The microspheres are smooth and transparent enough that light can bounce around inside them. “They act like miniature laser cavities,” Barnes explains. Light of the right wavelength “can travel around the microsphere for hundreds of round trips.” Because the microspheres are linked to each other, these optical resonances can pass between them and propagate through the chain structure. This effect could be useful in optical “wires” for sensors and other light pipe devices that could be tuned to a specific wavelength, the researchers believe.

Beyond optoelectronics, the chains might also be useful as magnetic coatings. Trapping magnetic particles within the microspheres might offer a new way to coat magnetic storage media like hard disks: Simply paint on the magnetized chains.

Mark Kuzyk of Washington State University in Pullman is impressed with the results and expects improvements in the technique. “In the future they will undoubtedly make more complex and better controlled geometries.” He adds that the researchers might be able to make a highly periodic, crystal-like structure, or “photonic crystal,” out of the microspheres, and thereby control light propagation in another way.

–David Bradley

David Bradley is a writer at sciencebase.com in Cambridge, UK.