Non-Euclidean Spring

Special plastic sheets, as well as ripple-shaped leaves, have in-plane stresses that cause them to wrinkle rather than lie flat. These so called non-Euclidean plates (NEPs) might be used in self-assembly applications, where they would fold spontaneously into some desired shape. New theoretical work has investigated a spring made from a ribbon of non-Euclidean material. Surprisingly, the properties of the NEP spring do not depend very much on the width of the ribbon: a fat spring and a narrow spring have roughly the same stiffness.

Researchers create NEPs through deformation of plastic sheets or by inducing nonuniform swelling in gels. These materials have an “incompatible” elasticity in the sense that no shape minimizes both the stretching and bending elastic energies. If thin enough, NEPs will bend into a nonflat configuration to reduce the in-plane stress.

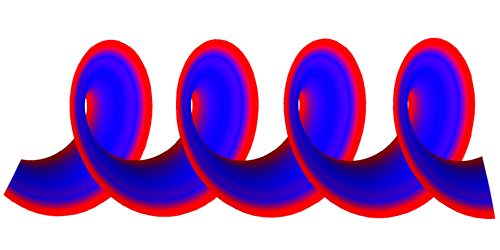

While previous work typically looked at the internal forces that shape NEPs, little has been done to explore how NEPs might respond to an external force or load. Ido Levin and Eran Sharon from the Hebrew University of Jerusalem, Israel, imagined a mechanical spring made from a thin NEP ribbon. They showed that the ribbon spontaneously curled into a helical shape, and they then calculated how the stiffness of this structure depends on the ribbon’s thickness and width. They found that the stiffness does not change—or decreases slightly—when the ribbon’s width is increased. This contrasts sharply with commonly used ribbon springs, which are normally cut from pre-curved materials and which become stiffer with increasing width. In addition, the NEP springs are “ultrasoft” in the sense that the decrease of their stiffness with thickness is sharper than in ordinary springs.

–Michael Schirber

This research is published in Physical Review Letters.