Foamy Flows

Studying foams might seem like a tasty job—whipped cream, chocolate mousse, and beer heads are foams–but engineering ideal foams is harder than tasting them. Foam researchers have learned that the bubbles in fresh foam enlarge over time, that the liquid between them drains out, and that these two processes affect each other. But they haven’t had a detailed and accurate theory describing the interaction. Now a team reporting in the 14 May PRL has developed such a theory and shown that it agrees with their experiments. The theory is a step toward a more complete understanding of foams, with possible applications in areas from beer production to mineral purification.

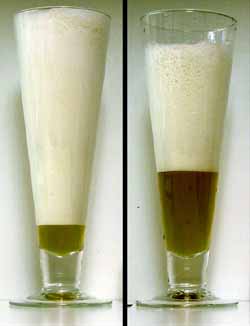

Imagine the stable froth of an ice cream soda. If you could forego drinking it for a while, you would see two distinct processes taking place: The bubbles enlarge–a process called coarsening–and liquid drains out. The coarsening occurs because smaller bubbles burst, but also because of the higher gas pressure in small bubbles, which makes them deflate as gas diffuses into larger bubbles. The larger bubbles provide wider “channels” between them, which accelerates liquid drainage.

To better understand the interplay between coarsening and drainage, a team led by Howard Stone of Harvard University filled a 2-m-long closed tube with soap bubbles and watched the liquid drain out. They held the tube horizontally during the filling process, then tilted it to vertical and measured the height of the column of liquid that gradually accumulated at the tube’s bottom end.

The researchers used two different gases to make foam: which diffuses easily from bubble to bubble, and which diffuses very slowly and essentially eliminates coarsening. As expected, the team found that drainage proceeded at least 10 times slower when coarsening was eliminated by the gas. They were also not surprised that the foam drained more quickly when it had a higher liquid content, because more liquid between the bubbles made the drainage channels larger. But they were surprised that the foam behaved differently–its drainage rate was largely unaffected by the foam’s liquid content.

After re-working their computer simulations, the team realized that the foam behavior came from an interaction between coarsening and drainage. They modified standard drainage equations to include this feedback. According to their model, adding liquid to the foam did not accelerate drainage because the extra liquid inhibited coarsening. In a very wet foam the bubbles are surrounded by thicker walls of liquid, which slows down gas diffusion between bubbles. With slower diffusion, the smaller bubbles remain longer and continue to slow drainage–an effect that compensates for the drainage acceleration caused by larger channels. Over time, drainage causes the bubble walls to thin, which accelerates coarsening; the faster coarsening accelerates drainage.

The team showed that their model fit the data–the first direct and quantitative study of the feedback between foam coarsening and drainage. “It shows very clearly that coarsening plays a role” in drainage, says Douglas Durian of the University of California at Los Angeles. “It’s a nice experiment,” he says, because the comparison of foams made with the two different gases cleanly separates the effects of coarsening, which other labs have not done so successfully.

Of course, long-lasting foam is not always a good thing. A major soft drink producer wants to apply foam research to reduce the excess foam emanating from soda fountains.