To Eliminate Defects, Create a Bend

Nanofabrication techniques that use templates to pattern devices could exploit so-called block copolymers for their designs. These molecules consist of two or more different polymer “blocks” that are bonded together. Large numbers of block copolymers can self-assemble, with the blocks grouping together by type to form patterns, such as periodic cylinders or stripes. However, defects in the patterns currently limit their use as high-fidelity templates. Now, Friederike Schmid of Johannes Gutenberg University Mainz, Germany, and colleagues have shown that bends in a block copolymer film can help align its periodic structures, reducing pattern imperfections.

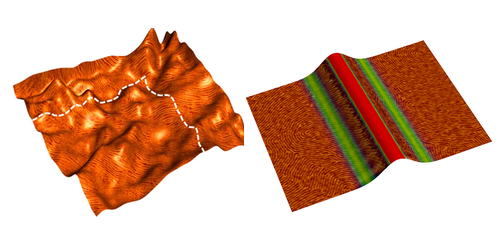

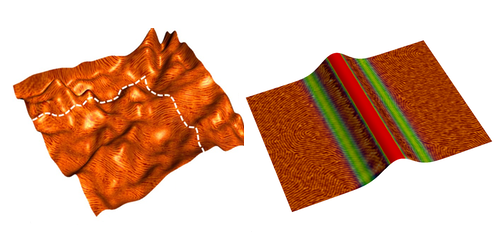

The team fabricated two 30-nm-thick films of the polymer called PS-PEP, which is comprised of a PS block and a PEP block. A film of the polymer was engineered to be free-standing, and it resembled a piece of paper that had been crumpled up and then reflattened. The other film, which had a smaller area of 25 , was formed on a humped substrate, and it looked like a pristine paper sheet that had been carefully draped over a long pipe. In both films, the PS block assembled into cylinders spaced 21 nm apart. Using atomic force microscopy, the team measured the cylinders’ orientations as a function of the film’s local curvature.

In the free-standing sample, the team observed that the cylinders pointed in all directions: Roughly two thirds of the cylinders lay either perpendicular or parallel to the film’s undulations, and the rest were randomly oriented. In the supported film, by contrast, they found that more than 90% of the cylinders aligned perpendicularly to the hump. The supported films, however, contained holes, which could hinder their use as templates. The team says that they should be able to prevent hole formation—and achieve 100% cylinder alignment—by controlling the interactions of the film with its supporting surface.

This research is published in Physical Review Letters.

–Christopher Crockett

Christopher Crockett is a freelance writer based in Arlington, Virginia.