Thickening Fluid Gets Even Thicker

A cornstarch-water mixture becomes more viscous and resistant to motion the faster it is stirred. This effect, called shear thickening, occurs in many liquids, and researchers have now shown that it can be enhanced in some cases by adding long, stringy polymers into the solution. The result came from measuring the properties of liquids containing polymers of various lengths. The finding may help engineers design better flexible body armor or smart materials that are liquid under normal conditions but turn solid under stress.

A liquid containing a high density of microscopic particles—a so-called colloidal suspension—can exhibit shear thickening. Researchers are still seeking a fundamental understanding of the effect. Previous experiments have found that the shear-thickening effect can be weakened or even completely eliminated by introducing short polymers into the solution, the presence of which induces weak attractive forces between the larger colloidal particles. Why this reduction takes place remains a matter of debate, as several competing physical effects play a role.

Now Jacinta Conrad of the University of Houston, Daniel Blair of Georgetown University in Washington, DC, and their colleagues, have discovered a distinct effect by which the addition of much longer polymer molecules leads to enhanced shear thickening. In a series of experiments, they tested the properties of a glycerol-water mixture containing 1.5-micrometer-diameter spherical particles to which they added polymers of different lengths.

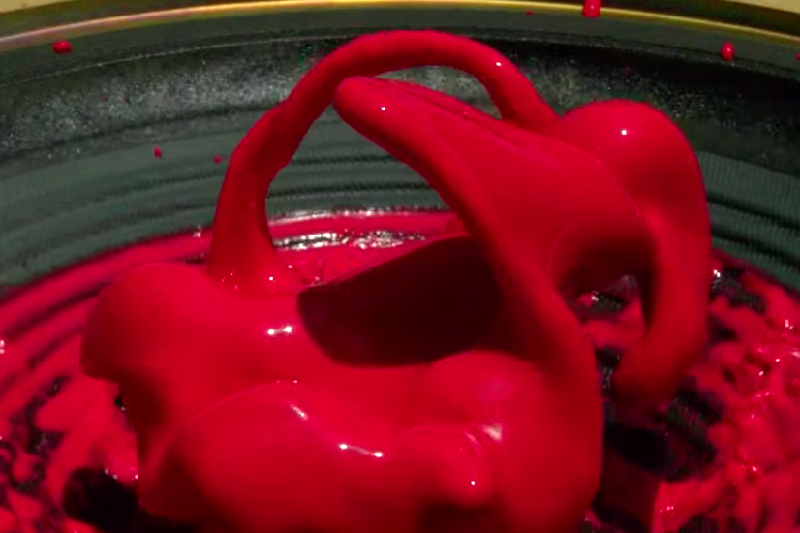

The team tested the solutions in a standard rheometer, where the blunt tip of a shallow cone points downward and nearly touches a flat plate. Fluid placed in the narrow space between the two surfaces is sheared as the cone rotates, and the device measures the force required to turn the cone as well as the pressure against the surfaces. Shorter polymers (0.6 micrometers long) slightly weakened the shear thickening effect at high shear, compared with a polymer-free solution, in agreement with earlier experiments. But with longer polymers (about 4 micrometers long), the team observed strongly enhanced shear thickening. In addition, the suspension containing short polymers pulled inward at high shear, while the larger polymers caused the fluid to press outward.

These results, Conrad says, when combined with recent theoretical and experimental work by others, point to a possible explanation for the enhanced shear thickening observed with long polymers. The shear stress appears to squeeze long polymers out of the smallest spaces between the particles and into larger voids. From there, the random motion of the polymers as they push against neighboring particles creates an effective attractive force among the particles. This attraction causes the particles to behave like grains of sand in a sandpile; a shear stress applied at one location has a long-distance effect as each particle pushes on its neighbors through the so-called contact network. This network leads to high viscosity and thus to an enhanced shear thickening effect. The shear stress applied by the rheometer caused the material to expand because each particle had to roll around others in order to slide past.

The short polymers are not easily excluded from tight spaces, so they appear not to influence shear thickening in the same way as long polymers. However, their small effect at high shear is consistent with earlier work. In the rheometer, the suspensions with short polymers contracted when sheared, presumably because high-density clusters formed and reduced the fluid volume. This cluster formation is one of the standard models of shear thickening.

“This work is surprising,” says chemical engineer Lilian Hsiao of North Carolina State University in Raleigh. “It goes against previous thoughts that the addition of polymers would mask the shear thickening.” The discovery, she suggests, could help engineers, who often add polymers into suspensions to tune viscosity, which affects how fluids flow in many industrial processes. “The work provides a map for fine tuning polymers to design complex flows of particles, which we find in everyday life, including in oil slurries, foods, and many consumer products.”

The team believes that their results should be useful in designing polymer additives of different sizes for use in adjusting the strength of the thickening effect in particle suspensions. This ability could enable the development of smart materials that can change their characteristics according to conditions. These materials would have uses in safeguarding industrial equipment operating in extreme conditions or in protective clothing, such as bullet-resistant vests or better helmets that reduce the risk of concussions.

This research is published in Physical Review Letters.

–Mark Buchanan

Mark Buchanan is a freelance science writer who splits his time between Abergavenny, UK, and Notre Dame de Courson, France.