Designing a Green Accelerator

Energy sustainability is a big deal for Erk Jensen, but it wasn’t always. Like other physicists who design machinery for particle accelerators, he spent much of his career chasing higher energies and brighter beams. But a decade ago, an alarming estimate about the power needs of a proposed high-energy accelerator for Europe changed his perspective. “If you have the power consumption of a small town for just this accelerator—which does nothing but produce some numbers for physicists—you have to do something about it,” says Jensen, who leads a large group of scientists and engineers at CERN, the European particle physics lab near Geneva.

At that time, Jensen says, he and his collaborators “were not even considering the questions of energy efficiency or environmental impact.” But he says that awareness about these issues has increased in recent years, as physicists have realized that their facilities’ energy usage can affect public support. Jensen is now one of a growing number of scientists in leadership positions who are speaking out about physicists’ responsibility to design more energy-efficient accelerators.

Research and development will help. Thanks to materials advances and clever new concepts, certain mainstays of accelerator machinery, such as radio-frequency cavities, could see leaps in efficiency. More radical changes could come from recycling the energy of accelerated particles or from repurposing waste heat to warm people’s homes. And just as accelerator technology has trickled outside of basic research into medical treatments, sanitation, and the semiconductor industry, physicists hope that their environmentally friendly strategies might also spin off to other industries.

The Energy-Hungry Machine

In 1931, Ernest Lawrence and Stanley Livingston constructed the first cyclotron, a circular particle accelerator and ancestor to many current designs. That first device was a mere 5 inches across and accelerated protons to 80,000 eV. Today there are roughly 30,000 accelerators around the world, mostly for medical use, with the largest—the Large Hadron Collider (LHC) at CERN—measuring 8.5 km in diameter and accelerating protons to 6.5 trillion eV.

The most powerful accelerators require huge amounts of energy. Running the LHC, for example, requires about 200 megawatts of power. Jensen says that early estimates for a post-LHC collider predicted that the machine would need up to 600 megawatts and thus could use as much power as all of Geneva.

“Particle physics always wants to reach higher energy and luminosity,” says Mike Seidel, who heads the Large Research Facilities division at the Paul Scherrer Institute in Switzerland and who is an active organizer of a biennial conference on sustainable science. “Unfortunately, that’s a direct function, in many cases, of the power that you draw from the grid.”

Plans for future accelerators pose a contradiction. Most scientists believe in sustainable energy usage, but the public might rightly ask, “How come those scientists now get a toy that uses so much energy?” says Thomas Roser, who chairs the Collider-Accelerator Department at Brookhaven National Laboratory (BNL) in New York.

Rebooting a World War II Technology

The main driver to increase accelerator efficiency has traditionally been cost, since a large electric bill quickly eats up an operations budget. Hefty power requirements may also overtax the existing grid. “Some of these really large machines that we’re dreaming about—they’re barely feasible with current technology,” says Matthias Liepe of Cornell University. “You’d have to build a nuclear plant to run them, and that’s certainly not within what’s possible or [what] can be funded.”

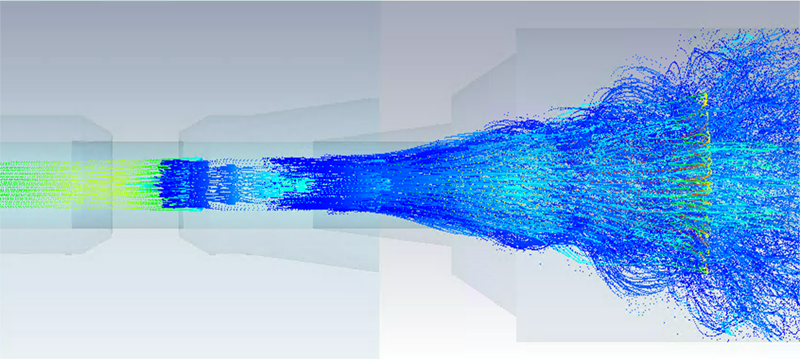

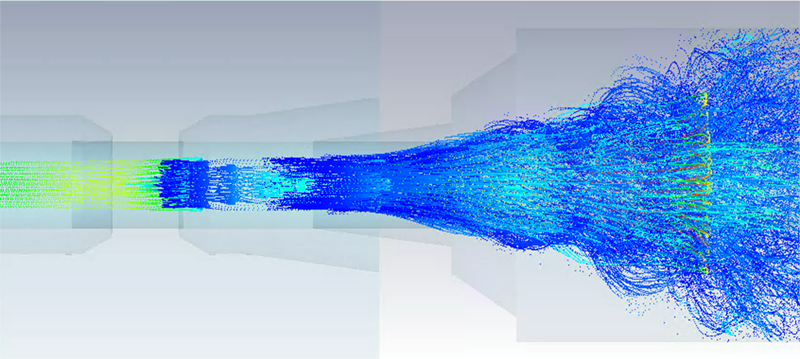

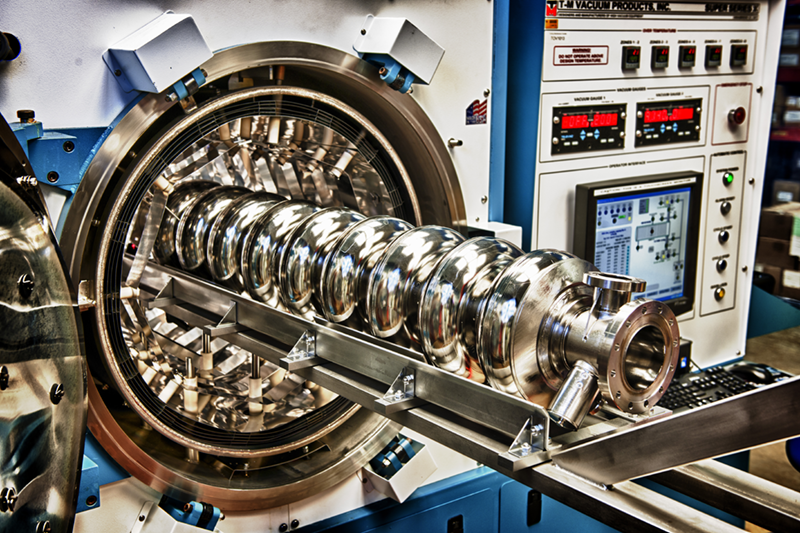

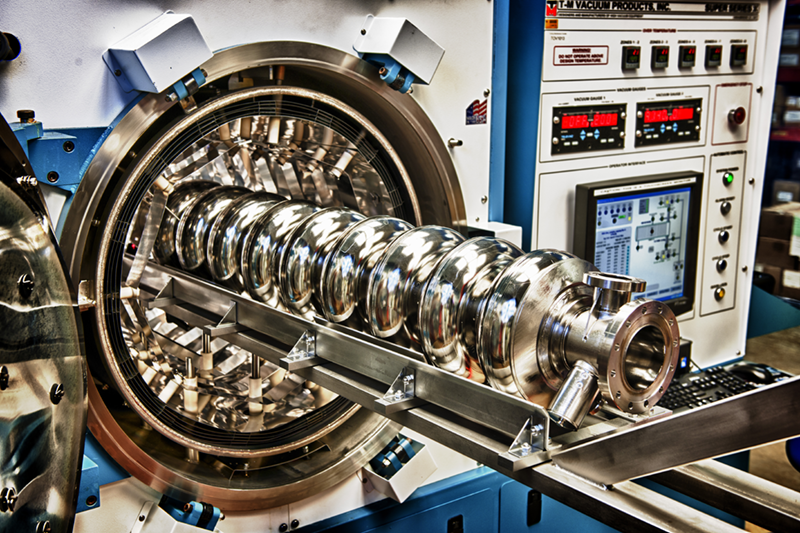

So researchers have always tried to maximize the amount of energy from the grid that goes into a particle beam, rather than being lost as heat. In most high-energy accelerators, the particles are driven as they move through a sequence of several-meters-long metal enclosures, or cavities. Each cavity is connected to a device called a klystron that produces intense radio-frequency (rf) electromagnetic waves that build up in the cavity. These oscillations are carefully timed so that when a group (or “bunch”) of charged particles enters the cavity, it receives a forward push (see explanatory videos from CERN and Fermilab).

An unexpected opportunity for saving energy resulted from recent work with klystrons, which were invented in the 1930s and were first used to generate radio waves during World War II. These rf devices can consume about half of an accelerator’s energy budget, explains Igor Syratchev, an accelerator physicist at CERN. But until recently, researchers assumed that the 70% efficiency of commercial klystrons was as high as it could get (efficiency here is the ratio of the output rf power to the input dc power from the grid).

Starting in 2010, Syratchev and Chiara Marrelli, a postdoc in Jensen’s group who is now at the European Spallation Source (ESS) in Sweden, set out to study and improve klystron efficiency. In a chance encounter with a Russian team’s work at a 2013 conference, Syratchev learned of a new, high-efficiency technology for handling electrons that could be applied to a klystron’s internal electron beam. Over the next five years, Syratchev, Marrelli, and their colleagues used computer simulation tools to design various klystrons that harnessed the new technology and that could have greater than 80% efficiency [1].

Syratchev estimates that increasing the klystron efficiency from 70 to 85% would save CERN’s proposed Compact Linear Collider (CLIC) 2.5 terawatt-hours over 10 years—enough to power about 50,000 Swiss households over the same time period. He expects testing of the first prototypes within a few years. Frank Zimmermann, an accelerator physicist at CERN, was surprised by the klystron improvements. “This is amazing: You have a technology; you thought it’s at the end, and after 80 years, suddenly some innovation.”

New Materials for Accelerator Cavities

Cooling the cavities, which are heated by the rf fields, is another major contributor to an accelerator’s energy bills. Superconducting rf (SRF) cavities, for example, are commonly used because they dissipate little energy from the rf field, so that the field is minimally distorted. But SRF cavities are made of superconducting niobium, which must be chilled to 2 K, and heat extraction at this temperature is very inefficient and requires expensive equipment.

One way to reduce these cooling costs is to improve niobium’s properties in order to cut the already tiny field energy losses in an SRF cavity. About eight years ago, researchers at Jefferson Laboratory (J-Lab) in Virginia and Fermilab in Illinois discovered that they could double a cavity’s “quality factor”—a measure of the degree to which losses have been suppressed—by embedding small amounts of titanium or nitrogen in the niobium. Pashupati Dhakal of J-Lab estimates that the improvement could cut cavity-cooling electricity bills by up to 4 times. Cavities produced with the nitrogen-enhanced material will get their first use at the upgraded version of the Linac Coherent Light Source (LCLS-II) at the SLAC National Accelerator Laboratory in California, now under construction.

Another option for reducing cooling costs is to replace niobium with a superconducting material that can be used at a higher temperature, where heat extraction would be more efficient. Niobium became the standard decades ago because it has some useful properties. But in 2014, Liepe and his colleagues demonstrated a cavity made from niobium tin ( Nb3Sn) that would require cooling to only about 4 K. Researchers working with Nb3Sn are “getting very close to the first applications for accelerators,” Liepe says.

After Reduce: Re-Use and Recycle

Before the community was so concerned with cutting energy for social reasons, improvements in rf accelerator efficiency had already been pushed pretty far by the “money argument,” says Mats Lindroos, who heads the accelerator group at ESS, under construction outside of Lund, Sweden. To take a bigger stab at reducing total energy usage, ESS is one of several facilities that are trying to re-use the large amount of energy that would normally be lost.

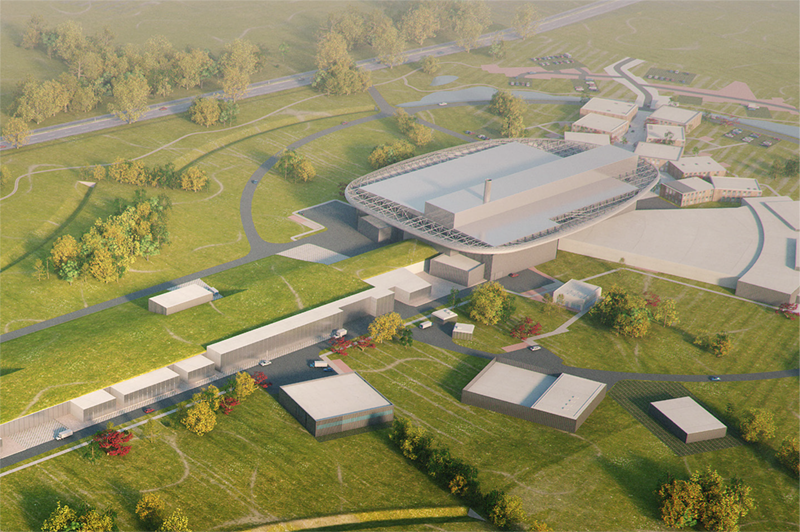

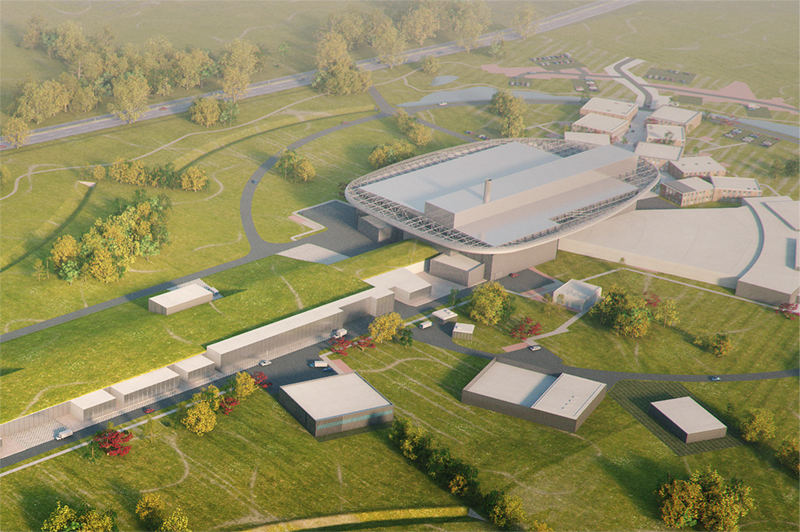

ESS is a neutron source that was initially pitched as a carbon neutral research center—an early concept even had a dedicated windfarm. But even with a less-ambitious plan, the facility is being built on Swedish farmland, which allowed planners to completely rethink the infrastructure design. “It started from scratch,” says Lindroos.

As Lindroos explains, only a quarter of the energy input goes into the beam itself; the rest becomes heat that is absorbed by cooling water. Hot water isn’t good for much, other than heating things, but that’s just fine for a cold climate like Sweden’s. In 2018, ESS signed an agreement with the German utility E.ON, in which the company promised to provide cooling water to ESS and to work with the local energy company Kraftringen to recoup the hot water for heating homes in Lund. The plan began its first phase earlier this year. And in a testament to Nordic bicycle culture, Kraftringen intends to use some warm water to de-ice bicycle paths. “It’s a societal benefit,” says Lindroos; winter biking accidents lead to “a big influx of people to the hospital with broken legs.”

Heat re-use isn’t an option for facilities that don’t have Sweden’s cold climate or the right municipal infrastructure. Another re-use concept, called energy recovery, extracts energy from the unused part of a particle beam. In circular colliders, for instance, two beams circulate in opposite directions around a loop to collide with each other, but very few particles interact in any given circuit. So after the collision point, the timing of the rf oscillations can be shifted with respect to the particle bunches so that when the beam passes through a cavity, the particles give their energy back to the field instead of taking it away.

A number of facilities around the world already use energy recovery, but the idea of using the technique explicitly to reduce energy consumption is a “newer development,” says Roser. Earlier this year, he and BNL colleagues Maria Chamizo-Llatas and Vladimir Litvinenko proposed a concept for a circular electron-positron collider that would reduce power consumption dramatically by recovering not only the particle energy but also the particles themselves [2]. With “one third of the power consumption, it’s possible to reach higher energy and productivity of a facility,” says Litvinenko.

The Right Time to Innovate

Seidel, Jensen, Roser, and other scientists have worked to make sustainability part of the planning process for new accelerator facilities by organizing and speaking at conferences for the past decade. For example, last year in Granada, Spain, where researchers and policy makers gathered to work on the European Strategy for Particle Physics (ESPP), Jensen told a crowded room that particle physics has a “duty to society” to design efficient machines [3]. The US version of the ESPP is Snowmass 2021, a year-long series of planning workshops, and earlier this year, Roser convinced the accelerator groups involved to make energy efficiency a goal of these meetings.

All of the physicists interviewed for this article emphasized that no solution can come at the expense of performance, or else particle physicists won’t get behind it. But with big accelerator projects on the horizon in Europe, China, Japan, and the US, researchers say that the timing is right to innovate. The latest ESPP, reported in June (see Research News: Europeans Decide on Particle Physics Strategy), states that any future project must provide a detailed plan for “saving and re-use of energy.” On September 9, CERN released its first public environmental report, promising to limit a rise in energy consumption to 5% through 2024, even as the LHC ramps up in performance. And in the US, researchers are gearing up for Snowmass 2021 (see Opinion: Exploring Futures for Particle Physics) and the design phase for the Electron Ion Collider, the successor to the Relativistic Heavy Ion Collider at BNL.

“The scientific community is brainstorming and discussing how to address the next challenges in particle physics,” says Chamizo-Llatas, “so it is a good time for out-of-the-box ideas.”

–Jessica Thomas

Jessica Thomas is the Editor of Physics.

References

- J. Cai and I. Syratchev, “KlyC: 1.5-D large-signal simulation code for kystrons,” IEEE Trans. Plasma Sci. 47, 1734 (2019).

- V. N. Litvinenko et al., “High-energy high-luminosity e+e− collider using energy-recovery linacs,” Phys. Lett. B 804, 135394 (2020).

- Erk Jensen’s presentation slides from ESPP 2019 (pdf).