Wrinkles Turn to Crumples

Trying to force a sheet of plastic, cloth, or other flexible material into a desired shape often leads to unpredictable wrinkles and folds. But researchers have now shown that the appearance of some of these distortions conforms to subtle rules. According to their experiments, thin sheets of many different kinds respond similarly to geometric distortions by forming gentle wrinkles, which, under the right conditions, give way to crumples or folds that concentrate stress into smaller zones. This understanding could help researchers designing industrial handling machines or polymer sheets that must unfold during the deployment of satellites.

Anyone trying to pull a sheet onto a bed encounters wrinkles, which minimize stretching of the fabric in favor of lower-energy bending. Wrinkle formation is a common response of any elastic material under gentle deforming forces.

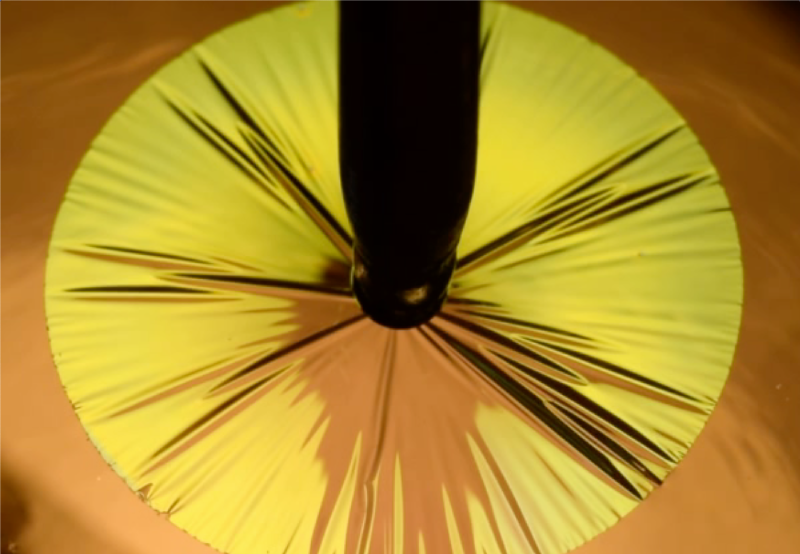

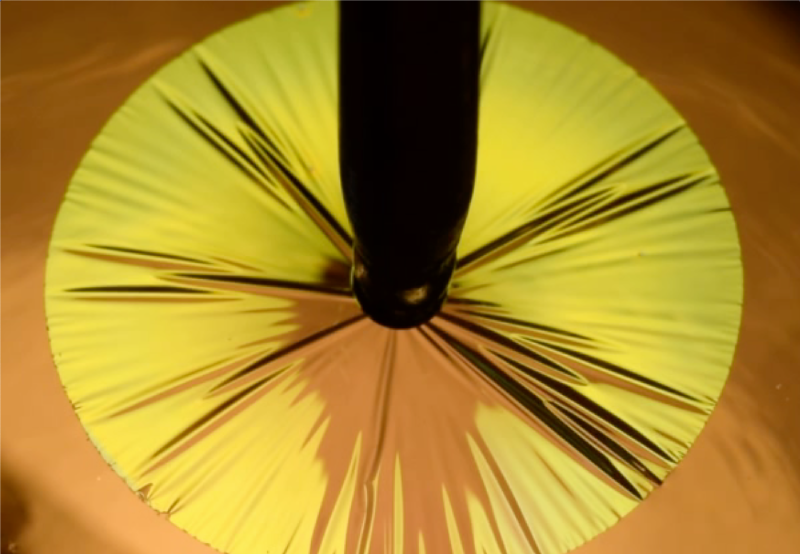

But thin sheets under stronger distortion do something different. In 2012, physicists found an intriguing effect when observing very thin circular sheets of flexible polymer distorting themselves to fit onto an underlying spherical surface [1]. When the curvature of the surface is small enough, the circular sheet adapts by forming smooth, radially-directed wrinkles around its outer edge. As the curvature grows, however, there comes a point at which some wrinkles transform into sharper and more localized structures that the researchers called crumples.

Now Joseph Paulsen and colleagues at Syracuse University in New York have examined how common this “wrinkle-to-crumple” transition might be. They deformed sheets of a wide range of materials using several unrelated geometries, measuring the surface undulations in detail with a laser scanner. In one experiment, the team studied a rectangular, inflatable pillow that they had fabricated from mylar plastic. When filled with air at high pressure, the pillow puffed out, the mylar being nearly flat and only deforming in gentle wrinkles. At lower pressure, the surface instead formed a smaller number of more localized crumples (see video). The pattern was qualitatively identical to the earlier experiments with thin rubber sheets, but in a completely different setting.

In all of the transitions they observed, Paulsen and colleagues found that a single parameter could predict when wrinkles would give way to crumples. That key parameter was the ratio of the imposed curvature to the tensile strain (the amount of stretching in response to in-plane forces). The more curvature, the more the sheet is compelled to bend, favoring crumples, which save energy by concentrating the distortions into small regions. Increased strain tends to keep the sheet flat, which favors wrinkles, because they spread the overall distortion out into smaller-amplitude undulations. The forces varied by a factor of more than 10 from one experiment to the next, but crumples appeared whenever the parameter surpassed a certain fixed value.

The researchers were surprised by the number of materials that show the same behavior. After many of the experiments were completed, the team realized that they could use the results for stiff plastic materials to predict when a soft rubber balloon might form crumples. "So we did the experiment," says Paulsen, "and there they were!"

“We find that crumpling is a generic response that occurs over a vast array of conditions,” says Paulsen. “It happens with soft rubber sheets or stiff polymer films, or using sheets having widths of millimeters or many centimeters.” He says that nature seems to use this process to help sheets contort in many geometrically-tricky situations.

“It's fascinating to find that a simple object such as an inflated balloon contains puzzles of interest to scientific research,” says soft-matter physicist Benoit Roman of the Institute of Industrial Physics and Chemistry (ESPCI Paris). “This paper may not completely solve the mystery of how these crumples appear, but it takes a significant step by identifying common behaviors in very different systems.”

Paulsen believes a deeper understanding of crumple formation could help in the engineering of elastic sheets. For example, crumples could potentially cause damage in “synthetic skins” used in robots or in industrial processing, where the material needs to repeatedly deform in predictable ways.

This research is published in Physical Review X.

–Mark Buchanan

Mark Buchanan is a freelance science writer who splits his time between Abergavenny, UK, and Notre Dame de Courson, France.

References

- H. King et al., “Elastic sheet on a liquid drop reveals wrinkling and crumpling as distinct symmetry-breaking instabilities,” Proc. Natl. Acad. Sci. U.S.A 109, 9716 (2012).