Heat Carried by Electron Waves

As electronic devices get ever smaller, keeping them cool is a major challenge. Even tiny electric currents can produce enough heating to damage very small components. New experiments show that surface electron waves called surface plasmon polaritons (SPPs) could help to dissipate heat in microscale devices [1]. The researchers measured the heat carried by these surface excitations in thin metal films and found that the SPP contribution could boost the total heat dissipation by as much as a quarter. Further engineering of such films might increase the amount of heat carried away by SPPs.

The density with which devices such as transistors are now packed into integrated circuits makes thermal management one of the biggest challenges for electronic and information technologies. When components such as thin films of metals or semiconductors reach nanoscale dimensions, the problem may be worsened by the fact that the collective atomic vibrations (called phonons) of the materials are so confined that they cannot conduct heat efficiently away from hot spots.

One way to compensate for this size effect is to mobilize other types of excitation to dissipate heat. Some researchers have sought to exploit surface phonon polaritons [2, 3], which are collective vibrations of the atomic lattice that interact with light waves at the material surface. But so far no one has shown any enhancement of heat conductivity from these excitations in the most common device configuration, a thin film lying on top of another material.

Bong Jae Lee of the Korea Advanced Institute of Science and Technology and co-workers figured that a different but related surface excitation, the SPP, might do the job instead. Here the wave-like excitation that couples to a light wave occurs not in the vibrations of the atoms but in the mobile electrons that carry current near the surface. The electrons in a thin film might thus transport heat energy away from a hot spot by forming SPPs that travel across the surface.

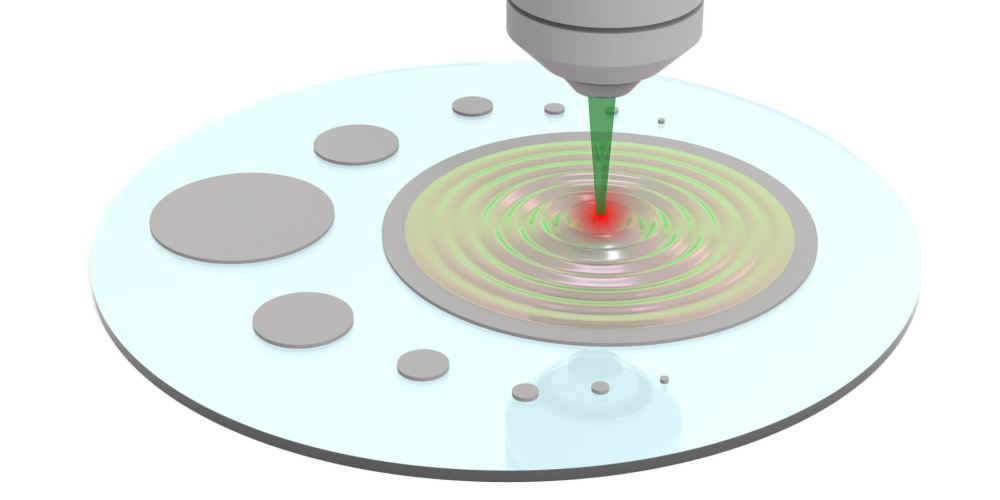

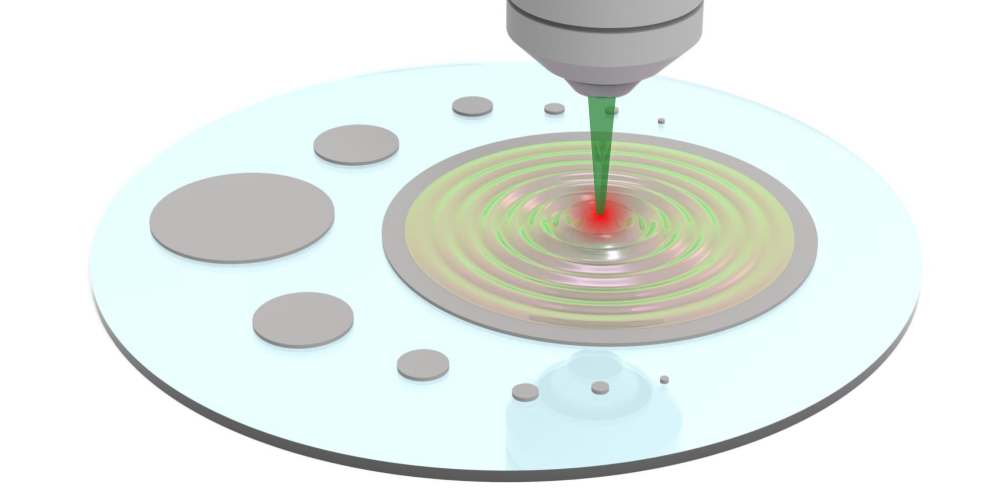

To test the idea, Lee and colleagues measured heat dissipation in a thin disk-shaped film of the metal titanium sitting on a thicker slab of insulating silicon dioxide (the substrate). They used a laser to induce local heating of the film and a method called thermoreflectance to monitor how the heat was dissipated. The heating spontaneously produced SPPs, both on the top surface (exposed to air) and the bottom surface (in contact with the substrate).

To figure out the contribution from SPPs to the dissipation, the researchers used disks of various radii. SPPs typically propagate for several centimeters before decaying significantly. But if the disk radius is much smaller than this decay distance, the SPPs are forced to decay more quickly, commensurate with that smaller radius—and this lessens the SPP contribution to heat conduction. Lee and colleagues found that heat dissipation from the laser-heated spot was greater for a disk with radius 28 mm than for one with radius 0.2 mm.

From this size dependence, they deduced that SPPs can increase the heat conduction at the film surface by up to 25%, relative to its value deeper in the bulk of the metal. “There is still room for further improvement,” Lee says. One possible way to increase the dissipation is to use different metals and substrates with less propensity to absorb SPP excitations.

The dissipation effect works best for metal films of a particular thickness—here around 70 nm. If the films are much thicker, the heat-conduction channels at the surfaces become less significant compared with the conduction through the bulk of the material. If the films are thinner, the SPPs at the top and bottom surfaces of the film interact and interfere with one another, reducing the conduction efficiency.

“This is the first experimental demonstration that SPPs contribute to heat transfer,” says Masahiro Nomura of the University of Tokyo, a specialist in the thermal physics of semiconductor nanostructures. “This demonstration is very important, since it opens a new heat-transfer channel.”

“While the measured enhancement [of heat conductivity] is limited, further studies and engineering will likely achieve large values,” says electrical engineer Alessandro Alabastri of Rice University in Texas. “If so, SPPs may provide an additional knob to manipulate heat transfer at the nanoscale, with significant advantages in microdevices and optoelectronics.” He cautions, however, that the need for relatively large widths of the films will limit engineers’ ability to take advantage of SPPs for the smallest systems.

–Philip Ball

Philip Ball is a freelance science writer in London. His latest book is How Life Works (Picador, 2024).

References

- D. Kim et al., “Boosting thermal conductivity by surface plasmon polaritons propagating along a thin Ti film,” Phys. Rev. Lett. 130, 176302 (2023).

- D.-Z. A. Chen et al., “Surface phonon-polariton mediated thermal conductivity enhancement of amorphous thin films,” Phys. Rev. B 72, 155435 (2005).

- Y. Wu et al., “Enhanced thermal conduction by surface phonon-polaritons,” Sci. Adv. 6 (2020).