Ultrablack Coating Could Reduce Stray Light in Telescopes

If you’ve tried to sleep in a hotel room, you’ll know that unexpected sources of light—from under a door or a glowing electronic sign—can negatively impact your rest. This problem of stray light also affects space telescopes that rely on dark conditions to see distant, faint sources. Accidental reflections from instrument components can make observations unnecessarily fuzzy.

Now Yunzhen Cao and Lin Lv from the Shanghai Institute of Ceramics, Chinese Academy of Sciences and colleagues have created a new kind of light-absorbing film consisting of multiple layers that can absorb nearly all light over wavelengths ranging from 400 to 1000 nm [1]. Compared to other “ultrablack” coatings, the film is more versatile and more robust, which could make it a good choice for future space missions.

Ultrablack materials absorb nearly all incident light over a certain frequency range. They occur in nature (providing camouflage to deep-sea creatures), in industry (absorbing sunlight for energy harvesting), and in science (reducing stray light for sensitive optical devices). Two popular ultrablack substances are vertically aligned carbon nanotubes and black silicon, both of which exhibit over 99% light absorption, but the fragility of these materials can make them unsuitable for space-telescope applications, Lv says.

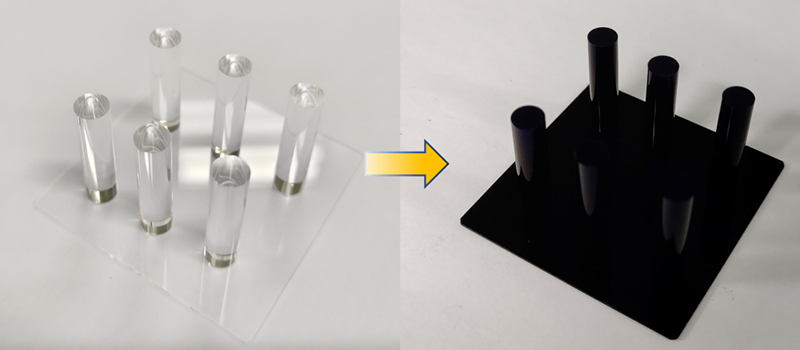

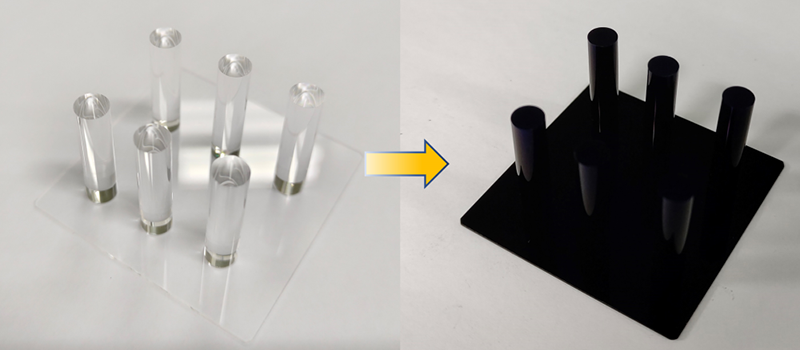

Another drawback with current ultrablack materials is that they can’t easily be applied to curved surfaces, such as the inside of a tube or the exterior of a circular post. Cao, Lv, and their colleagues wanted to address these problems by using a vacuum-based fabrication method, called atomic layer deposition (ALD), that could evenly apply a thin film to a variety of geometries. “One big advantage of the ALD method lies in its excellent step-coverage ability, which means we can obtain uniform film coverage on very complex surfaces, such as cylinders, pillars, and trenches,” Lv says.

Using ALD, the researchers developed an ultrablack film composed of layers of a titanium aluminum carbon (TiAlC) composite and silicon dioxide (SiO2). While other ultrablack films rely on physical qualities for light absorption, such as black silicon’s rough surface texture, the light absorption of the ALD film is derived from both the intrinsic optical absorption of its component materials and the way that these materials are layered. In particular, the metallic compound TiAlC is a reasonable choice for light absorption, says Jonathan Spanier, an engineer and physicist at Drexel University in Pennsylvania who was not involved with this work. He imagines that the absorption of TiAlC is a result of its diffuse light scattering and limited specular backscattering created by its morphology.

Alone, Lv says that TiAlC can absorb 70% of incoming visible light, and when paired with a layer of SiO2, it can absorb 89% of light. To further reduce the amount of nonabsorbed light, Lv and colleagues combined multiple layers of these materials. “As a result, nearly all of the incident light is trapped in the multilayer film,” Lv says.

To fabricate their film, the researchers started with precursor compounds—including titanium tetrachloride, trimethyl aluminum, diisopropylaminosilane, and ozone. These ingredients were alternately passed into the ALD reaction chamber, transforming them into layers of TiAlC and SiO2. After testing different layer combinations, the team determined that a six-layer stack of these compounds created the optimal environment to absorb up to 99.4% of wavelengths between 400 and 1000 nm.

To test the robustness of the film, the team exposed samples to high-humidity conditions (95% relative humidity) for 24 hours. They also scratched the surface of the samples using sandpaper. The film maintained an average light-absorption rate of 99.1% after the humidity tests and 86.3% after the abrasion tests, making it a promising candidate for applications in extreme environments, Lv says.

Charles Falco, a professor of optical sciences at the University of Arizona, says the robustness of the film sets it apart—even though the absorption rate and range remain lower overall than those of its predecessors. “The research is quite thorough, and the authors have explored a number of parameters, so it is an important contribution to the field,” Falco says. He suggests that future work on these films should investigate expanding the absorption range from ultraviolet (100 nm) to near infrared (1100 nm).

Lv says the team does plan to explore methods to expand the absorption range of their film in the future. They are also working to reduce fabrication temperatures by exploring alternative compounds to TiAlC. With these future developments, Lv hopes this film can find a place in space observation and precision optics.

–Sarah Wells

Sarah Wells is an independent science journalist based outside of Washington, DC.

References

- J. Jin et al., “Robust ultrablack film deposited on large-curvature magnesium alloy by atomic layer deposition,” J. Vac. Sci. Technol., A 42 (2024).