Mimicking an Elephant Trunk

Elephants use their trunks for various tasks by exploiting a remarkable range of motions. A research team has now shown that much of this dexterity can be achieved using just a small number of muscle-like actuators [1]. Using both theoretical calculations and experiments with a simple physical model of a trunk, the researchers found that their minimal model can reproduce the complex bending and torsional motions seen in real trunks. The results might be useful in the design of “soft robotics” devices.

An elephant’s trunk is used for drinking, for feeding, and for grasping objects, such as the vegetation that the animal strips for food. The proboscis is controlled by 17 groups of muscles running longitudinally along the trunk’s axis [2]. “There have been many soft-robot designs inspired by the elephant trunk,” says mathematician Alain Goriely of the University of Oxford in the UK. Most of these don’t mimic the muscle system of real trunks but instead use tubes divided into multiple hard segments that are controlled individually. Some approaches have instead used pneumatics to induce bending and twisting of tubular structures [3].

But to understand the basic design elements needed for such versatile movement and to gain insight into how real trunks operate, Goriely and his co-workers sought to recreate trunk-like motions using a simple set of contractile actuator elements that reflect the longitudinal musculature of the real organ.

“The challenge was to find a way to develop both curvature and torsion,” says Goriely. Making the trunk curl into a spiral-type shape is relatively easy. As the team’s mathematical model confirmed, this action requires a single contractile actuator running longitudinally on one side of a tapering trunk, like the bimetallic strips in the thermostats of electric kettles. But a trunk also has helical muscle fibers that induce torsion, creating movements in three dimensions that allow the trunk to thoroughly explore its surroundings.

The researchers calculated that helical actuators winding around the trunk axis can generate a wide range of torsional motions. They studied several designs and found that the most versatile one had a single straight actuator for curling, plus two helical actuators, one winding to the left and one to the right, for torsional motion. “The question was then to see what such a structure can achieve,” says Goriely.

One way to assess the abilities of such model trunks is to determine the amount of the surrounding space that they can access—what the researchers call the reachability cloud—for given limits on the amount of contraction allowed by the actuators (chosen to reflect the properties of real elephant muscles). With simple models, it is possible to calculate these limits numerically. The reachable volume turned out to be greater for the “three-muscle” design than for, say, small sets of solely helical or longitudinal actuators.

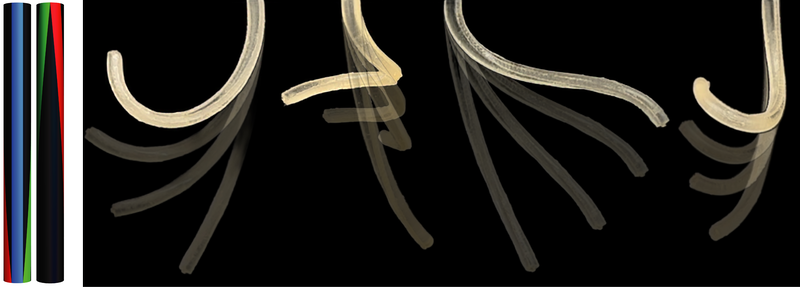

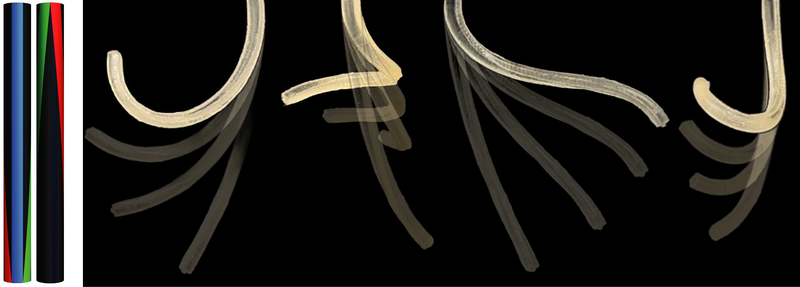

Goriely and colleagues then tested their predictions experimentally with a “minimal trunk”: a cylinder of a rubbery material controlled by three actuator strips comprised of a liquid-crystal elastomer that contracts in one direction when heated. The actuators were deposited onto the cylinder surface using 3D printing, and embedded in them were copper wires that could warm the material electrically, so that each actuator could be controlled independently.

As predicted, this structure could be induced to adopt a wide range of shapes, including simple curling, torsion in either direction, and combinations of both deformation modes. These movements could mimic those of real trunks, which have been documented by others using motion-capture technology [4].

The researchers think their design could be used to make soft, versatile appendages for robotics. Goriely says their approach might also shed light on the motions of climbing plants (driven by differential tissue growth [5]) and of octopus arms.

Mechanical engineer David Hu of the Georgia Institute of Technology calls the work “a triumph of mathematics and an important step in reverse engineering the elephant trunk.” He says that the important result is in “reducing the biological complexity to three degrees of freedom.” Biologist Michel Milinkovitch of the University of Geneva, who has studied the biomechanics of elephant trunks, says, “this minimal-design approach is very attractive,” although at this early stage it comes with limitations: the artificial trunk cannot be elongated or shortened, he says, and “it is unclear how it could efficiently handle small and large loads.”

Hu adds that “the big question left in my mind is this: If elephants can achieve all these 3D trunk positions with just three actuators, why does it have to have so many other muscles, and when are those used?”

–Philip Ball

Philip Ball is a freelance science writer in London. His latest book is How Life Works (Picador, 2024).

References

- B. Kaczmarski et al., “Minimal design of the elephant trunk as an active filament,” Phys. Rev. Lett. 132, 248402 (2024).

- L. L. Longren et al., “Dense reconstruction of elephant trunk musculature,” Curr. Biol. 33, 4713 (2023).

- S. H. Kim et al., “A physics-informed, vision-based method to reconstruct all deformation modes in slender bodies,” Int. Conf. Robotics and Automation (ICRA) 4810 (2022).

- P. Dagenais et al., “Elephants evolved strategies reducing the biomechanical complexity of their trunk,” Curr. Biol. 31, 4727 (2021).

- D. E. Moulton et al., “Multiscale integration of environmental stimuli in plant tropism produces complex behaviors,” Proc. Natl. Acad. Sci. U.S.A. 117, 32226 (2020).