Surface Folds Make Tears and Chips

Most people think that solids, in contrast to liquids and gases, do not change their shape irreversibly in response to small stresses. The more refined view is that solids deform plastically, with the deformation persisting after the stress is removed. This can occur even under small stress through the thermally activated motion of defects, when the solid is given enough time to relax. The process resulting in the shape change of solids under stress is not completely clear, but suggestions are that it resembles the process of the laminar flow of fluids. However, when stresses exceed a critical value, laminar flow becomes unstable. Above this critical stress level, fluids often develop turbulence, while for high enough stresses, solids will crack, or if they are ductile and malleable, will form shear bands, which are narrow zones of intense shearing strain.

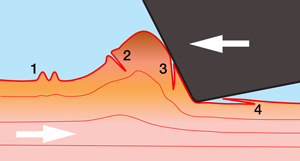

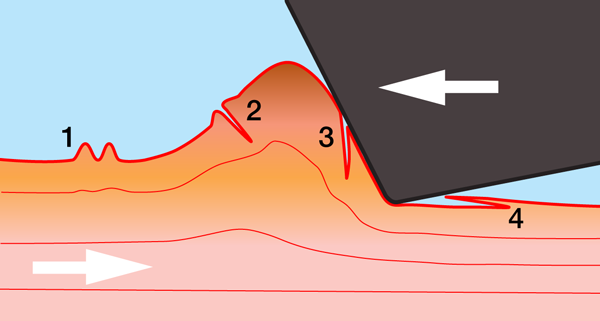

Writing in Physical Review Letters, Narayan Sundaram and colleagues at Purdue University, Indiana, propose that the response of solids may turn out to be more fluidlike than previously believed [1]. The team detected turbulent vortexlike structures in copper, which were produced by the sliding motion of a hard steel wedge indenter against the copper surface at velocities of about 1 mm/s. Similar fluidlike instabilities in sliding solid interfaces have been predicted in nanometer-scale molecular dynamics simulations [2], but the new results are nevertheless surprising: the experiments were performed at velocities several orders of magnitude smaller than the simulations and the flow instabilities were triggered in an extended region ahead of the actual point of contact, rather than at the interface between the sliding solids. Using particle image velocimetry, the team observed that within a range of wedge incidence angles, “bumps” arose in the copper surface a few hundred microns ahead of the indenter’s wedge. The morphology of these bumps looked similar to the undulating protuberances of fluids near a hydraulic jump (a sudden rise in liquid height often observed at a sudden velocity decrease). As the wedge approached the bumps, they sometimes interacted and grew into folds, which got buried underneath the steel wedge. The folds were elongated while emerging from underneath the tip, producing isolated tears and open folds. A schematic of the folding dynamics is shown in Fig. 1. The material above the crack ( 4 in Fig. 1) is only loosely connected to the substrate and can easily be sheared off to produce thin platelets or chips, which are typical for metallic debris [3].

Sundaram et al. modeled their experiments by carrying out finite element simulations in which the material is divided into “cells,” and found striking similarity with the experimental features when assigning different plasticity (but identical elasticity) to the individual grains with a typical size slightly exceeding 100 microns. The simulations reveal that softer cells are squeezed upward to produce the bumps on the surface. They mutually attract under the compressive action of the tip to form the folds, which emerge at the surface as fold or crack features in the wake of the wedge, just like in the experiments.

Simulating an undulating but mechanically homogeneous monocrystalline solid did not turn out to be successful. In order to observe folds in these homogeneous simulations, it was necessary to start with a large initial sinusoidal amplitude that far exceeded the experimental roughness amplitude. So, surface roughness cannot explain the experimentally observed folds, and thus the heterogeneity due to the grains in the solid is the most likely rationalization. The new study therefore adds to the established view that platelet-shaped metallic debris particles arise as the consequence of stretching and delamination from cyclic loading or an initially rough surface [3]: The particles can also emerge as a consequence of a plastic instability caused by heterogeneous grains eventually inducing mesoscale folding of the surface.

Note that the observed plastic instability should not be related to the elastic buckling instabilities of objects, since the latter are scale free and independent of the grain size, while the observed formation of bumps and folds is intimately connected to the grain size of the investigated material. Nevertheless, it would be interesting to investigate to what extent quantitative parallels can be drawn with continuum fluid dynamics. Qualitative discussions of this sort have been proposed not only in nanotribology [2], but also in a geological context [4].

The wedge investigated in the new study can be thought of as a small-scale machining tool, or alternatively, as a polishing grain, which is attached to a work wheel or part of a polishing paste. The study by the Purdue researchers reveals that a road to improving the surface quality of machined metals lies in a better control of the grain geometry and its impact angle with the metal. This insight bears the promise to design future machining equipment in a more targeted and controlled fashion than presently possible.

References

- N. K. Sundaram, Y. Guo, and S. Chandrasekar, ”Mesoscale Folding, Instability, and Disruption of Laminar Flow in Metal Surfaces,” Phys. Rev. Lett. 109, 106001 (2012)

- D. A. Rigney and S. Karthikeyan, “The Evolution of Tribomaterial During Sliding: A Brief Introduction,” Tribol. Lett. 39, 3 (2010)

- K. L. Johnson, “Contact Mechanics and the Wear of Metals,” Wear 190, 162 (1995)

- Y. Y. Kagan, “Seismicity - Turbulence of Solids”, ” Nonlinear. Sci. Today 2, 1 (1992)