Light-Powered Jets

Imagine a laser-powered squirt gun shooting a stream smaller than the width of a human hair. That’s essentially what researchers report in the 11 April PRL. The researchers used the pressure of laser light to create a micrometer-scale liquid jet at the interface between two liquids of different densities. This is the first example of a stable and continuous optically-powered microjet. It could lead to improvements in devices that use liquid jets, as well as microjets that guide light.

Liquid microjets have many commercial, medical, and industrial applications. They’re used as ink sprayers in inkjet printers, as cutting tools for microsurgery, and as sample fillers in gene chip technology. Microjets can be powered by compressed air, thermal bubbles, and even acoustic waves. But a laser-powered microjet would allow the size and other jet properties to be controlled easily during use, simply by adjusting the laser, says Alexis Casner of Bordeaux University in France.

The difficulty for Casner and Bordeaux colleague Jean-Pierre Delville in creating such a jet is that the pushing force exerted by a laser, even at high power, is very weak. To get this weak force to effectively push a liquid surface, the team produced a liquid interface with low surface tension. They whipped up a mixture of water, a type of alcohol, an oily chemical called toluene, and a soap-like chemical called a surfactant. The mixture forms nano-sized droplets of water, alcohol, and surfactant within the toluene. Above a critical temperature, it separates vertically into two phases with different concentrations of droplets, and a low-surface-tension interface forms horizontally between the phases.

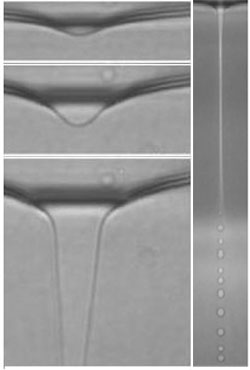

The researchers directed a laser beam downward–from the low-concentration side–and pushed a “bump” out into the other phase. As they increased the laser power, the bump grew larger, and its shape changed, which affected the refraction of laser light across the interface. At a critical power the laser beam experienced “total internal reflection,” a condition where light is entirely reflected. This complete reflection maximized the pressure on the liquid surface and pushed the small bump into a jet. The team controlled the jet’s direction by varying the direction of the laser beam.

After traveling some distance as a steady stream, the jet broke up into evenly-spaced, equally-sized droplets. The researchers could control the frequency and size of the droplets by varying the power of the laser. This property of the microjet may be useful, explains Delville, particularly in manufacturing emulsions. Many products–including many foods and medicines–are emulsions made up of droplets of one liquid dispersed within another, and this technique could give manufacturers an unprecedented amount of control over their size.

The researchers also say that laser-powered microjets might someday be used to guide light, because light from the laser travels through the microjet as it would through an optical fiber. Such a “liquid optical fiber” would have the advantage of being perfectly adapted to the beam that created it and might be useful in optical circuits.

Michael Brenner of Harvard University praises the creativity of the work. He says other types of waves have been used to make jets before, but not light waves. Elisha Moses of the Weizmann Institute in Israel says that the microjets could have important applications. If researchers can find appropriate two-fluid systems, he says, “then it’s a very neat method.”

–Lea Winerman

Lea Winerman is a freelance science writer.

More Information

Response to this paper: Phys. Rev. Lett. 92, 049401 (2004)