Breaking Glass under a Microscope

If you dropped a wineglass, you’d expect it to shatter, not skitter across the floor like a silver goblet would. But research published in the 21 February print issue of PRL suggests that glass does in fact break like a metal–at least at the nanometer scale. The research may help explain some of the fracture properties of glass, and may someday lead to stronger versions of the material.

Researchers generally categorize fracture modes into two classes. Ductile fracture occurs in metals, which can bend before they shatter. Brittle materials like glass can’t bend, and so they break more easily. Researchers have traditionally thought that cracks in brittle materials grow because applied stress causes atomic bonds to stretch and pull apart at the tip of the crack. This process would produce sharp crack tips and smooth fracture surfaces. In contrast, ductile fractures occur because stress causes pockets of empty space called damage cavities to form ahead of the crack tip. These cavities grow and coalesce to propagate the crack, a process which leads to rough, uneven fracture surfaces.

At the millimeter and micrometer scales, the difference between glass’s smooth fracture surface and metal’s rough one is clear. In recent years, though, researchers have looked more closely at broken glass and noticed that its fracture surface is rougher than they had previously thought. Using an atomic force microscope (AFM), researchers examined fractured glass at the nanometer scale and found rough, metal-like surfaces.

That prompted some to wonder whether the ways in which glass and metal break are really so different after all. “It seemed that the topographic features of metals and glass were not so different,” says Christian Marlière of Montpellier University in France. “Why not think that the fracture processes are also equivalent?”

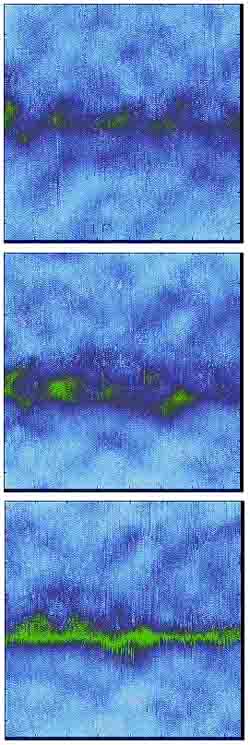

To test this theory, Marlière’s group collaborated with colleagues at France’s Atomic Energy Commission (CEA) in Saclay. The researchers placed a 4 x 4 x 40-millimeter block of glass vertically inside a chamber and slowly squeezed on the small top and bottom faces with a compression machine. A one-millimeter-diameter hole went horizontally through the middle of the block. The squeezing pressure caused it to bow apart in the middle, and cracks slowly propagated vertically up and down from the hole. The team used an atomic force microscope (AFM) to watch one resulting crack as it developed. The AFM, which measures the topography of a surface, revealed tiny valleys ahead of the crack tip, and the team showed that these were nanoscale damage cavities. “So the way glasses and metals rupture is very similar,” says Marlière, but at a thousand times smaller scale for glasses.

Elisabeth Bouchaud, head of the CEA group, says the research may have implications for glass manufacturers. Right now, she says, manufacturers have a good understanding of glass’s empirical fracture properties–how much stress a certain type of glass can withstand before cracking, for example. “What we hope,” she says, “is that we can give them a better understanding of the effect of glass composition on damage properties.” That might help manufacturers develop different types of glass particularly suited for different jobs.

James Rice of Harvard University says that fracturing glass has never before been carefully examined at the nanometer scale. “This study is certainly significant,” he says, “because it presents evidence that the actual way extremely brittle materials fracture is different from what has commonly been imagined.”

–Lea Winerman

Lea Winerman is a freelance science writer.