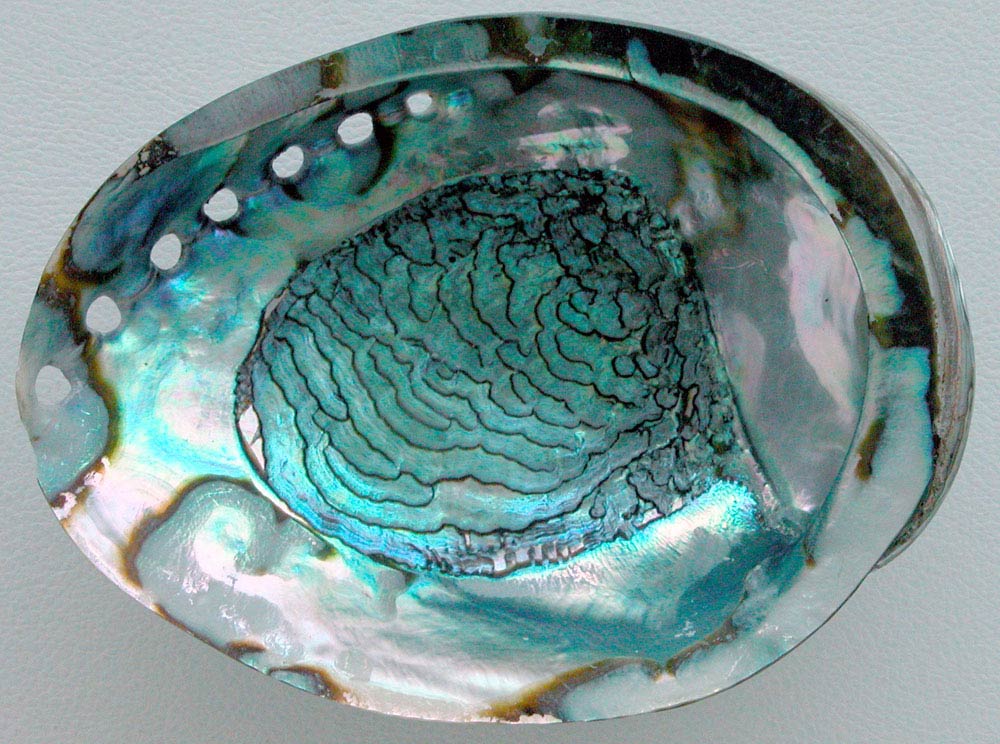

Inside Mother-of-Pearl

Researchers have revealed new details of the microscopic architecture of mother-of-pearl, or nacre. Using an x-ray technique, the team determined the orientation of the crystalline structure within the calcium carbonate “bricks” that make up the material. They found that adjacent bricks can have different crystal orientations, even though their faces are parallel and stack neatly together, as they describe in the 29 June Physical Review Letters. The team proposes a mechanism for nacre growth and says that improved understanding of the nacre structure could provide inspiration for new types of engineered materials.

Nacre is made mostly of aragonite–a calcium carbonate crystal–arranged in 500-nanometer-thick layers. It forms from ions in seawater that washes through an organic “scaffold” of thin, interconnected, horizontal sheets–the animal essentially lays the “mortar” before filling in the “bricks.” The iridescence of mother-of-pearl comes from the interference of light as it reflects from the thin, crystalline layers. But the beauty is only part of what drew Pupa Gilbert, of the University of Wisconsin, Madison, to study nacre. “Materials scientists have been interested in mother-of-pearl for decades because this material is 3000 times more resistant to fracture than its components,” she says, referring to the organic and crystalline constituents.

The aragonite crystals are shaped more like irregular disks than like bricks, and each one is offset from the one below. The alternating tablet and scaffold layers look a bit like single layers of coins touching at their edges, alternating with sheets of paper. Researchers have studied the tablet architecture and the components of nacre with various microscopes, but there hasn’t been a good way to see both the atomic-scale crystal alignment and the details of the tablet architecture at the same time.

To investigate the nacre structure, Gilbert and her colleagues used a technique that hadn’t been applied to biominerals before. They hit a portion of a nacre sample edge-on with a polarized x-ray beam tuned to a resonant frequency of the carbon-oxygen bonds. They then focused the electrons ejected from the sample to make an image–a grayscale map showing a mosaic of differently shaded areas representing regions with different crystal orientations.

The team found that the layers were not necessarily aligned with the atomic-scale crystal structure, and neighboring tablets could have different crystalline orientations. But groups of up to 40 tablets with identically oriented structures tended to form ragged columns within the sample, like snaking stacks of quarters.

The team also proposes a way that nacre might grow. It forms layer-by-layer from the bottom up, and some researchers have assumed that each crystalline tablet grows right on top of the one below, with only slight sideways offsets. The tablets may be connected through small holes piercing the scaffold layers. Gilbert and her colleagues propose that the holes–or some kind of nucleation sites that trigger crystal growth–are randomly scattered throughout the scaffold layers and not necessarily vertically aligned. As each tablet grows, it will likely hit the scaffold “ceiling” first but continue to grow horizontally for some time. Eventually it will meet a hole or nucleation site that can start another tablet growing in the level above, and finally, the tablet will stop expanding when it hits a neighboring tablet.

This growth scenario leads to the highly skewed columns of identically oriented crystals that the team observed. The columns peter out on their upward path as neighboring columns encroach from the sides–quite different from the usual model of columns that grow continuously upward. Cracks are less likely to propagate through such a structure because they run into crystal boundaries, says James De Yoreo of the Lawrence Livermore National Laboratory in California.

According to the new data, “the intrinsic properties of crystal growth aren’t what’s driving [the architecture],” says Adam Hitchcock of McMaster University in Canada. “Biology has a major role to play.”

–Stephanie Chasteen

Stephanie Chasteen is a freelance writer and physics graduate student at the University of California at Santa Cruz.