Metallic Glass isn’t All Glassy

Metallic glasses can be strong, corrosion- and wear-resistant, yet break abruptly. Researchers don’t understand their structure well enough to explain these properties, but in Physical Review Letters, a team provides new structural details, suggesting that the materials are more orderly than expected. Using a specialized electron microscopy technique, they discovered regions of crystalline order amid the disorder expected for glasses. The team hopes that a better understanding of the structure of metallic glasses will lead to explanations for their unusual properties and improvements in the manufacturing process.

If the rumor that the upcoming iPhone 5 will be sheathed in metallic glass is true, Apple is putting a lot of faith in a substance that materials scientists don’t fully understand. Metallic glasses are metals, but like window glass, they don’t have an ordered, crystalline structure, the way most metals and minerals do.

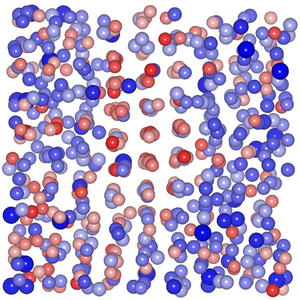

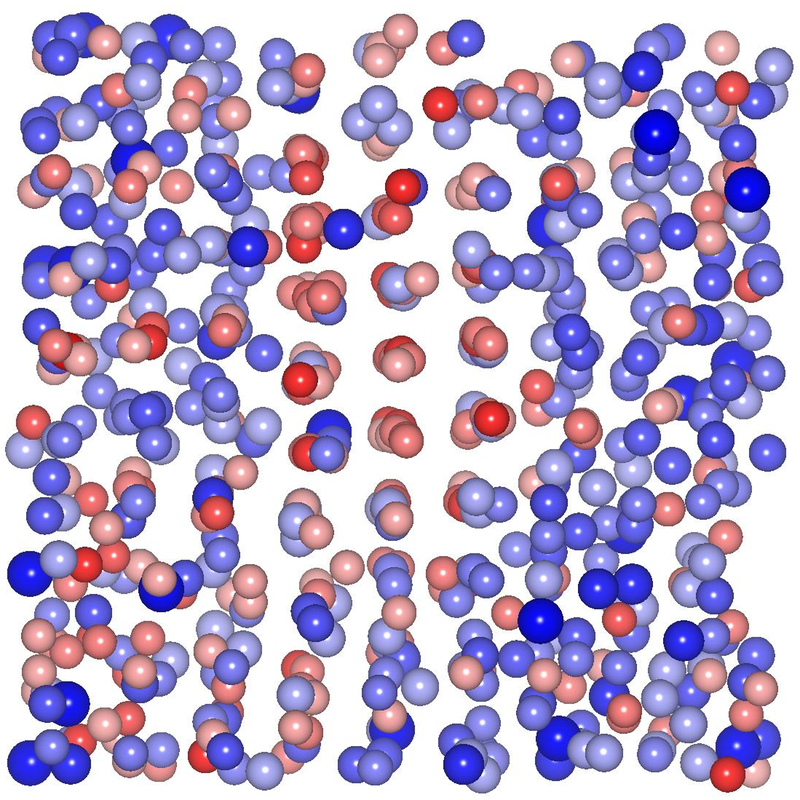

But materials scientists suspect that metallic glasses do have some kind of semi-ordered structure, even if it isn’t a perfect crystal. The prevailing theory is that “clusters” of atoms—groups that include a central atom and its nearest neighbors—form distorted pentagons or icosahedrons (the three-dimensional equivalent of a pentagon). These shapes have fivefold symmetry, so they are mathematically impossible to arrange into a perfectly repetitive pattern. Materials with fivefold symmetry tend to shatter, rather than stretch or bend under stress, which also describes metallic glasses. Another theory holds that groups of clusters pack into crystalline arrangements a nanometer or more across, but this idea is controversial.

The fivefold symmetry theory is supported by computer models, but these simulations can only reveal so much. Paul Voyles of the University of Wisconsin in Madison and his colleagues have now added some experimental data to a computer model and come up with a more complex picture.

The team used a technique called fluctuation electron microscopy (FEM) to probe samples of the metallic glass Zr50Cu45Al5. FEM measures variations in the scattering (diffraction) of electrons as the electron beam is moved across the surface of a thin sample. A perfectly homogeneous sample—whether crystalline or amorphous—would have very little variation in its diffraction pattern. But if the sample has some degree of variation on the scale of one or a few nanometers, such as small regions of atoms with structures that differ from neighboring regions, the diffraction will vary noticeably. The technique is sensitive to a “medium-range” length scale that is difficult to probe with conventional electron microscopy or x-ray diffraction.

Feeding the FEM data into a computer simulation, the researchers found that different areas of the sample had different types of symmetry. Some regions were made of icosahedra, and some looked more cubic. The cubic, “crystal-like” regions occupied almost 15 percent of the initial sample, which was rapidly cooled from the molten state. The fraction went down after the team heated the sample to room temperature for an hour, suggesting that the true equilibrium state reached after long heating times might have very little crystal-like structure.

Voyles admits that the data are from only one of many possible metallic glasses, so other varieties could be different. And this may not be the ideal, lowest-energy state for the material. But since flash-cooling is the normal procedure to make metallic glasses in industry, this sample was worth measuring, Voyles says. “I like reality, and this is realistic.” The next step in the research will be to use clues from the structure to figure out how Zr50Cu45Al5 forms into a glass. The team also hopes to measure other metallic glasses.

The research is intriguing, and the results hint that the “cluster-packing” theory might be onto something, says Todd Hufnagel, a materials scientist at Johns Hopkins University in Baltimore. The small size of the simulations performed by Voyles’ group limits the amount of long-range order to be seen, but future experiments and simulations could illuminate that better, he says. Hufnagel says the work has affected his thinking about the topic. “I had been skeptical of that [cluster-packing model], but it seems to be showing up in Paul’s stuff.” He says Voyles’s team’s results will make him think carefully about higher-order atomic organization in metallic glasses.

–Kim Krieger

Kim Krieger is a freelance science writer in Norwalk, Connecticut.

More Information

Introduction to Fluctuation Microscopy (by P. Voyles)

What is Fluctuation Microscopy? (by M. Treacy, Arizona State University)