How to Control a Random Laser

A random laser doesn’t require the carefully designed mirrors needed for a normal laser, but in its most basic form, the light contains many colors and goes in many directions. Researchers can limit a random laser to a single, unpredictable wavelength, but now a team reporting in Physical Review Letters proposes a general technique to produce a selected wavelength. The system, which they demonstrate with computer simulations, would use a feedback loop to adjust the profile of the light source powering the laser. The result could lead to durable and customizable lasers, including the prospect of producing some wavelengths not available with conventional lasers.

A conventional laser contains a “lasing” medium, such as a gas, that amplifies the light as it bounces back and forth between a pair of mirrors. A random laser has no mirrors, and instead the light bounces around among scattering objects, such as zinc oxide particles floating in a liquid containing laser dye. Hit it with bright flashes of “pump” light, and the liquid will glow with laser light of many colors. Since a random laser lacks the precisely manufactured optical cavity that is sensitive to temperature and vibrations, it’s potentially cheaper and more robust than a regular laser. It might also be adjustable over a wide range of wavelengths.

First theorized in the late 1960s, random lasers became feasible a decade ago. One of the challenges has been controlling the wavelength. Using a low-power pump produces a single wavelength, but the wavelength that appears can’t be chosen in advance nor easily changed.

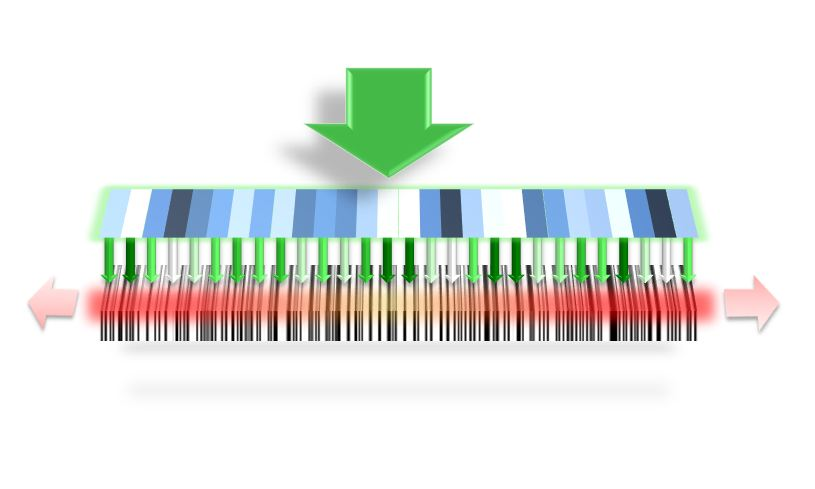

Now Patrick Sebbah of the Institute of Industrial Physics and Chemistry (ESPCI ParisTech), and his colleagues, have come up with a system that allows control of the wavelength, and they have demonstrated it with computer simulations. For simplicity, the team envisions a one-dimensional laser, similar to one reported in 2005 [1], but they say 2D and 3D lasers could work in a similar way. In the computer model, the laser consists of 161 slabs of lasing material of varying thickness (but near 100 nanometers) interleaved with air gaps of about 200 nanometers. The pump light comes in perpendicular to the main laser axis, and it goes through a so-called spatial light modulator (SLM) before hitting the laser. The SLM, a device found in LCD projectors, allows one to program the spatial profile of the light, choosing the precise intensity that will hit each slab of the laser.

In the simulation, a detector feeds information about the laser’s output beam back to the SLM, which continually modifies the profile of the pump light until the desired single-wavelength beam is reached. The system is based on the idea that a random laser has many “modes” within it. A mode is a portion of the laser that amplifies light of a specific wavelength. Under some conditions, these modes form isolated regions within the laser, but under other conditions, the modes spread across the entire device and form complicated overlapping patterns. Experiments have suggested that if the pump light hits only part of a random laser, then the output light only contains contributions produced by the modes that received pump light.

Sebbah and his colleagues show how to pump only a single mode chosen at the start. Pumping the mode could require a quite complex spatial pattern, but the iterative procedure zeroes in on that pattern, causing the laser to emit the mode’s wavelength. Once the laser operators find a pattern that produces a certain wavelength, they could switch rapidly between that pattern and other patterns that produce other wavelengths.

The team hopes that in the future, instead of building an expensive custom laser, researchers could take a simple powder and tune it for any application. “You start from something dirty, then you control it, you tame it,” says Sebbah. He envisions many uses for wavelength-selectable random lasers, such as sources for ultraviolet light, for which there are no good mirrors and thus no conventional lasers..

”I’m sure that many people will like this, and it offers a whole playground of different applications,” says Stefan Rotter of the Vienna University of Technology. The technique potentially reduces production time from several weeks to just a few seconds, he says. Instead of a costly manufacturing process, you simply change the laser using your spatial light modulator hooked up to your computer.

–Frank Smith

Frank Smith writes about science with a focus on light.

References

- V. Milner and A. Z. Genack, ”Photon Localization Laser: Low-Threshold Lasing in a Random Amplifying Layered Medium via Wave Localization,” Phys. Rev. Lett. 94, 073901 (2005)