Friction at the Atomic Scale

Everyone learns the basics of friction in high-school physics classes: the friction force experienced by a sliding object is proportional to the normal force that an object exerts on a surface. Remarkably, this extremely simple and empirical relation, known as Amontons’ Law, is still often used in creating the most technologically sophisticated machines and devices, even though friction is known to vary with a large number of other parameters not captured in this relation. For example, at the nanoscale, friction is significantly influenced by adhesion, an example where Amontons’ Law cannot predict the friction force [1]. Likewise, friction can depend on sliding speed, duration of contact, environment, temperature, and the sliding direction [1,2]. As reported in Physical Review Letters, Jay Weymouth and colleagues at the University of Regensburg in Germany have investigated the friction force at atomic length scales, using an atomic force microscope (AFM) [3] to probe the forces between a tungsten tip coated with a small amount of silicon, sliding on the surface of crystalline silicon. They report an observation never before obtained at the scale of just a few atoms: friction is strongly dependent on the orientation of specific silicon atomic bonds at the surface with respect to the sliding direction of the tip.

A directional dependence of friction, also known as friction anisotropy, has been previously observed on larger scales (at least a few nanometers). For example, a tip was pulled along a molecular layer where the molecules were locally all tilted in the same direction. Sliding along the tilt axis produced lower friction than when sliding perpendicular to it [4]. A similar behavior can be observed in a simple way by pressing one’s hands together (as if in prayer but with the fingers spaced apart). Upon sliding the fingers of the left hand against the fingers of right hand (perpendicular to the long axis of your fingers), the fingers of one hand become stuck in between those of the other. However, if one instead slides the left hand down and the right hand up (parallel to the long axis of your fingers), the hands move smoothly. The relative orientation between the sliding direction and the grooves of one’s fingers influences friction because of the geometry of our hands. Friction anisotropy has been observed by sliding a small tip on atomically flat and well-characterized surfaces [5]. However, in all these cases, the nanometer-size tip was pressed into contact with the surface, meaning that a large number (at least thousands) of atoms were in contact during this experiment.

Recent advances in AFM have led to the development of the highly sensitive frequency-modulation (FM) method [6], where the tip oscillates in the direction normal to the surface. In this AFM mode, attractive forces between the surface and the tip cause a change in the resonant frequency of the force sensor; the surface topography can be imaged by tracking the oscillator’s resonance frequency with very high precision. The tip can be brought within atomic distances of the surface without actually touching it. This “noncontact AFM” (nc-AFM) mode has been used to produce remarkable, atomically resolved images of surfaces, such as the first atomic resolution images of single pentacene molecules on surfaces [7], or the rearrangement of individual chemical bonds during surface chemical reactions [8]. A particularly sensitive method, pioneered by Giessibl’s group, uses the so-called “qPlus” sensor—a stiff quartz tuning fork with a sharp and conductive tungsten tip attached at its end [9]. The use of qPlus sensors in nc-AFM allows one to drive oscillations at amplitudes even smaller than the typical sizes of atoms, leading to resolution below one atom [10].

In the present work, Weymouth et al. built customized qPlus sensors that have been rotated by ° with respect to their typical orientation; this allows the tip to oscillate parallel, instead of perpendicular, to the surface and thus measure friction. This novel geometry allowed them to acquire the first atomic resolution image of the lateral frequency shift.

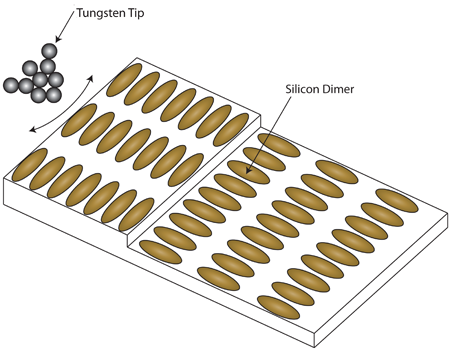

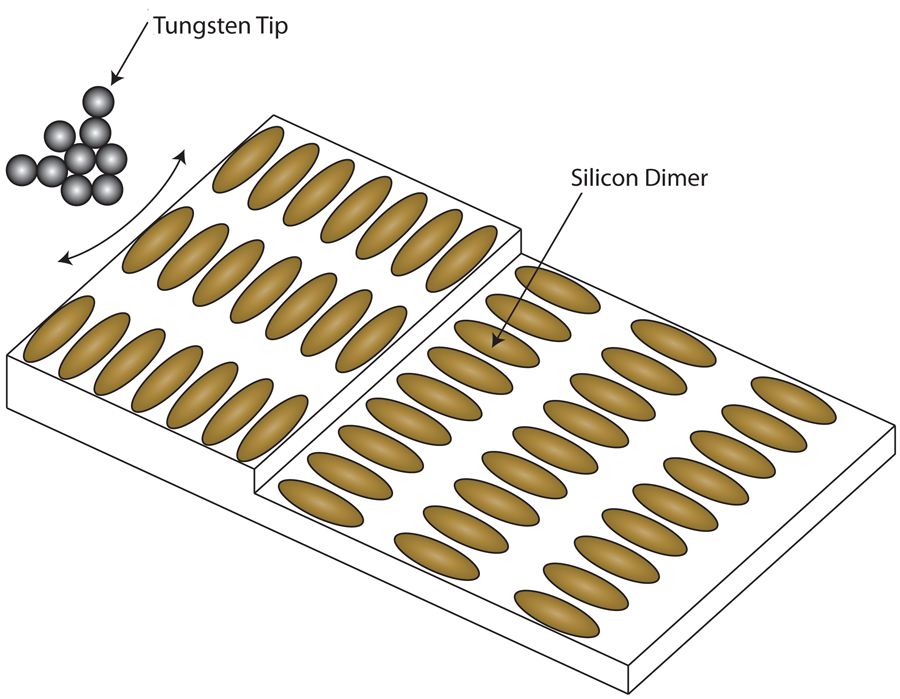

The silicon surface they studied consists of pairs, or “dimers” of silicon atoms that are all aligned along a single, crystallographically defined direction on the surface. The sample can be prepared so that there are two different regions (terraces) where the dimers are oriented in two perpendicular directions (see Fig. 1). The research team found that when the tip was sliding perpendicular to the dimers, the friction force showed a symmetric modulation at each dimer location. However, if the sliding was parallel to the dimers, the modulation became asymmetric. This difference could be directly attributed to the direction dependence of the lateral stiffness of the atomic bonds of the dimer.

Such atomic-scale studies have an important advantage: the authors can model the surface using a fully atomistic and quantum-mechanical simulation, which reproduces the experimental observable quantities well, such as normal or friction forces, normal or lateral stiffnesses, and the measured surface topography. Such simulations are needed as it is not possible, in even the most careful experiments [2], to simultaneously observe every atom on the surface and the tip while measuring normal and lateral forces. In contrast, simulations can address every single atom and allow the formulation of an atomically precise hypothesis to explain the experimental observations. Furthermore, quantum-mechanical simulations cannot yet reach the length scale of larger-scale friction studies with AFM (quantum-mechanical simulations are limited by available computer power to a few hundred atoms, whose dynamics can be simulated for only a few picoseconds). Thus the atomic-scale experiments by Weymouth and colleagues offered the chance for the first successful comparison of fully quantum-mechanical simulations with measurements.

While the results are obtained for a very specific anisotropic system, the work has more general impact in two key ways. First, it shows that atomically resolved lateral stiffness and lateral force measurements are possible. This opens up the possibility of future investigations of other materials and phenomena related to friction. Second, the fact that the calculations match so well the experimental data helps establish the accuracy of methods based on quantum-mechanical calculations. With further increases in computer power and algorithm efficiency, simulations of larger systems (more atoms) for longer times may realize virtual studies of phenomena not accessible to experiments.

Even though we know a great deal about friction, much about it remains a mystery. We do not have any equations to predict the amount of friction between two specified materials, and we do not understand and cannot quantitatively predict how friction will depend on temperature or the environment. However, through this combination of novel experiments and advanced simulations, the complex problem of friction is now being studied at the atomic scale—the most fundamental unit of contact. Such microscopic insights may help eventually move friction beyond previous empirical approaches to a point where, through bottom-up understanding of how friction originates, the properties of materials in sliding contact can eventually be predicted and controlled. A better understanding of friction will benefit applications ranging from the study of geological faults to the prediction of wear in automobile components or microelectromechanical systems (MEMS).

References

- C. M. Mate, Tribology on the Small Scale: A Bottom up Approach to Friction, Lubrication, and Wear (Oxford University Press, Oxford, 2008)[Amazon][WorldCat]

- I. Szlufarska, M. Chandross, and R. W. Carpick, “Recent Advances in Single-Asperity Nanotribology,” J. Phys. D: Applied Physics 41, 123001 (2008)

- A. J. Weymouth, D. Meuer, P. Mutombo, T. Wutscher, M. Ondracek, P. Jelinek, and F. J. Giessibl, “Atomic Structure Affects the Directional Dependence of Friction,” Phys. Rev. Lett. 111, 126103 (2013)

- M. Liley, D. Gourdon, D. Stamou, U. Meseth, T. M. Fischer, C. Lautz, H. Stahlberg, H. Vogel, N. A. Burnham, and C. Duschl, “Friction Anisotropy and Asymmetry of a Compliant Monolayer Induced by a Small Molecular Tilt,” Science 280, 273 (1998)

- U. Gehlert, J. Fang, and C. M. Knobler, “Relating the Organization of the Molecular Tilt Azimuth to Lateral-Force Images in Monolayers Transferred to Solid Substrates,” J. Phys. Chem. B 102, 2614 (1998); R. W. Carpick, D. Y. Sasaki, and A. R. Burns, “Large Friction Anisotropy of a Polydiacetylene Monolayer,” Tribol. Lett. 7, 79 (1999); H. Bluhm, D. Schwarz, P. Meyer, and R. Wiesendanger, “Anisotropy of Sliding Friction on the Triglycine Sulfate (010) Surface,” Appl. Phys. A 61, 525 (1995)

- T. R. Albrecht, P. Grütter, D. Horne, and D. Rugar, “Frequency Modulation Detection Using High-Q Cantilevers for Enhanced Force Microscope Sensitivity,” J. Appl. Phys. 69, 668 (1991)

- L. Gross, F. Mohn, N. Moll, P. Liljeroth, and G. Meyer, “The Chemical Structure of a Molecule Resolved by Atomic Force Microscopy,” Science 325, 1110 (2009)

- D. G. de Oteyza et al., “Direct Imaging of Covalent Bond Structure in Single-Molecule Chemical Reactions,” Science 340, 1434 (2013)

- F. J. Giessibl, “High-Speed Force Sensor for Force Microscopy and Profilometry Utilizing a Quartz Tuning Fork,” Appl. Phys. Lett. 73, 3956 (1998)

- F. J. Giessibl, S. Hembacher, H. Bielefeldt, and J. Mannhart, “Subatomic Features on the Silicon (111)-(7×7) Surface Observed by Atomic Force Microscopy,” Science 289, 422 (2000)