Tuning the Flow through a Soap Film

An electric field can drive fluid through a narrow pipe by pulling on ions in the liquid. Now researchers show in Physical Review Letters that an electric field can also pull fluid through a soap film, which is essentially a narrow channel with deformable walls. They also found that the film thickness increases with the electric field strength, which could be useful in controlling the flow of tiny fluid volumes in future labs-on-a-chip.

The emerging fields of microfluidics and nanofluidics offer the possibility of replacing a lab full of beakers with a single chip that can manipulate drops of fluid. These miniature chemistry labs can move fluid using electric fields that act on ions in the fluid. The ions are normally an equal mixture of positive and negative charges, but an excess of one type typically collects along the surface of the channel because the walls are charged. When these surface ions are pulled by an electric field, they drag fluid along with them, including all of the fluid from the interior (or “bulk”) of the channel. This flow—called electroosmosis—is dominant in micro- and nanochannels, where the surface-to-volume ratio is high. But little research has considered what might happen if this ratio were free to change, as in a soft-walled channel.

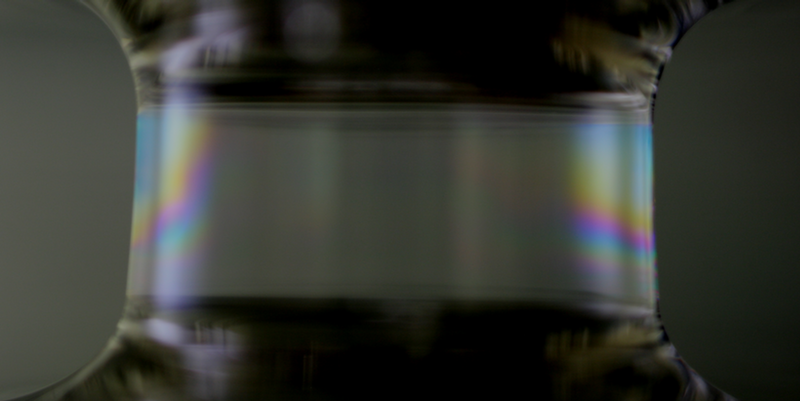

A soap film is a deformable channel made of two sheets of “surfactant” (soaplike) molecules that enclose a layer of water. Anne-Laure Biance and her colleagues from the University of Lyon in France investigated the effect of electric fields on soap films. They set up two horizontal plate electrodes, with one roughly half a centimeter above the other. The team wetted them with a soapy solution consisting of water, a surfactant, and potassium chloride to provide free ions. A vertical cylindrical film of the solution naturally formed between the electrodes. The channel walls in this case were two concentric cylindrical sheets of surfactant that allowed water and ions to flow up and down in the space between. The positively charged surfactant molecules attracted negatively charged chloride ions along the inner and outer walls.

The team applied different voltages to the electrodes and measured the current produced by moving ions. Using some preliminary measurements, the researchers were able to separate the surface ion contributions to this current from that of bulk ions. The surface current, as predicted, dragged fluid up through the soap film against the force of gravity. However, when the team increased the voltage, they noticed that the bulk current increased faster than expected. They deduced that the film was thickening, allowing more bulk current. They estimated that the thickness varied from less than 100 nanometers to several hundred nanometers. A wider channel allowed greater fluid flow, which they could verify by observing the rate of growth in the film’s upper meniscus.

To measure how the flow rate changed with voltage, the team drew on some previous theoretical work that describes how a vertical plate lifted out of a liquid bath can—through viscous forces—pull up, or entrain, a film of fluid. The surface layer of ionic current is like a moving plate that drags fluid up inside the soap film. Using this analogy, the team calculated that the flow rate should increase as the 5/3 power of the applied field, which agreed with their experimental data.

The researchers suggest that this steep dependence of flow rate on voltage could be used to build a fluidic device analogous to a common electronic component. It would essentially restrict fluid flow to zero until a certain threshold voltage was applied (similar to the “off/on” features of an electronic gate). “The interest is that this device would be low cost, with its properties mainly due to the deformability of the channel,” Biance says. The team is also interested in seeing if electric fields could be used to stabilize foams, which tend to collapse when water drains out of them due to gravity.

“[This work] breaks new ground by removing the solid walls that usually define the geometry of a nanofluidic system and control many of its important characteristics,” says Derek Stein of Brown University in Providence, Rhode Island. He says that soap films could help researchers investigate lingering questions about motion at the fluid-wall interface. “By simply changing the soap used to make the bubble, it should also be possible to tune the surface charge density, the surface tension, or other important physical parameters.”

–Michael Schirber

Michael Schirber is a Corresponding Editor for Physics Magazine based in Lyon, France.