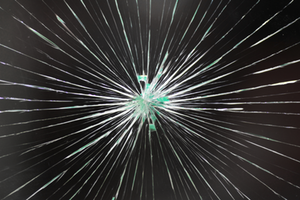

Windshield Cracks Hold Secrets of Impact

When a small rock hits a windshield, the cracks that appear are hardly a welcome sight, but the star-shaped pattern may contain information about the rock and the glass. Experimental results in Physical Review Letters show that the number of cracks radiating out from the impact point could reveal the collision velocity and the underlying material properties. The exact relationship found by the research team might prove useful in a forensic investigation to determine, for example, the speed of a vehicle or the energy in a bullet. It could also help in understanding cracklike features in archaeology and planetary science.

In the field of fracture mechanics, an important parameter is the fracture energy, which is a measure of the amount of energy it takes to form a crack. It is related to the surface energy of the material, because a crack creates new surface. Researchers typically assume that cracks form when a material is stressed to a point where the fracture energy is less than the corresponding elastic energy, or in other words, when breaking costs less energy than bending. Materials with the lowest fracture energies are the most brittle.

But once the crack has opened up, “few studies have asked the question, ‘what does the cracking pattern tell us?’” says Nicolas Vandenberghe of the Aix-Marseille University in Marseille, France. In a recent experiment, Vandenberghe and his colleagues studied perforations in aluminum foil and found that the number of tears (or cracks) showed some consistent behavior that could be explained with a theoretical model [1]. The team has now performed this same sort of “postmortem” analysis on a simple system that mimics a rock hitting a windshield.

For their experiment, Vandenberghe’s team selected plates of glass and Plexiglas with thicknesses from about half a millimeter to several millimeters. An air gun fired a bullet-shaped, 4-millimeter-diameter steel cylinder at the sheets with speeds between and meters per second. A high-speed camera tracked the crack initiation and development.

The first thing the researchers noticed was that the number of cracks was proportional to the square root of the impact speed. This result would imply that if a slow-moving rock hits your windshield when you’re driving at 80 miles per hour, you might expect twice as many cracks as a -mile-per-hour vehicle. Comparing materials, the researchers found that the number of cracks increased with increasing brittleness (decreasing fracture energy), as expected. To derive this behavior from basic physics principles, the team developed a formula for the total energy in a sheet, including both fracture and bending energies, and calculated the number of cracks that would minimize this energy. Their equations correctly predicted that the number of cracks should be proportional to the square root of the impact speed and to the inverse cube root of the fracture energy.

The team’s equations might help a forensic investigator piece together the details in an accident or a crime, Vandenberghe says. The model might also reveal the properties of an unknown material. For example, Jupiter’s ice-covered moon Europa has lines extending outward from meteorite impact craters in a pattern similar to the thin plate fractures. Planetary scientists might be able to learn something about the make-up of Europa by doing a careful counting survey of these ice structures.

Jan Åström from the Finnish Information Technology Center for Science (CSC) in Esbo says the research contributes to on-going efforts to characterize the fundamental aspects of fracture and fragmentation. Howard Stone of Princeton University imagines that this study could help researchers reconstruct fragmented objects from archaeological digs. “Obviously, there are likely differences in fragmentation depending on how the impact occurs,” Stone says, “but the present work provides new insights into how the number of cracks can vary and also is a nice example of a controlled study to probe these effects.”

–Michael Schirber

Michael Schirber is a Corresponding Editor for Physics Magazine based in Lyon, France.

References

- R. Vermorel, N. Vandenberghe, and E. Villermaux, “Radial Cracks in Perforated Thin Sheets,” Phys. Rev. Lett. 104, 175502 (2010)

More Information

Tutorial on basic fracture mechanics by Neil James of Plymouth University, UK