Holey Rubber Slab Has Controllable Stiffness

A new material has a tunable springiness. Simply by squeezing the rubbery material to different degrees, the researchers who developed it can predictably alter its stiffness over a wide range in a direction perpendicular to the squeeze. The material is a slab containing two different sized holes. Such a “programmable” material might find uses in robotics, medical prostheses, or ordinary footwear.

“Smart materials” have properties that can change in response to changes in their environment. For example, researchers have developed tunable vibration dampers for vehicles and for protecting buildings from earthquakes. These devices work by changing their stiffness, and thus the frequency at which they absorb vibrations. But they usually use piezoelectric materials, which require an electric field to change their properties. A purely mechanical technology that doesn’t rely on electric power could be cheaper and more robust.

Bastiaan Florijn and coworkers at the University of Leiden in the Netherlands have developed and tested such a structure. It is an example of a so-called metamaterial—a material whose properties derive from its macroscopic structure rather than from its composition. Previously mechanical metamaterials were used to make acoustic dampers that could be switched on and off by a small amount of compression [1], or for “unfeelability cloaks” that could deform to mask the presence of an object concealed beneath them [2]. But the new material has a variety of mechanical properties, rather than simply being switchable between two states.

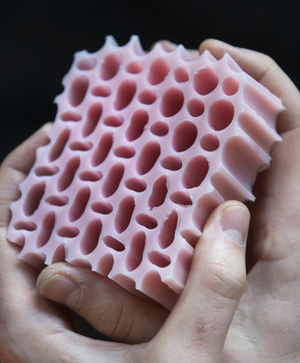

Florijn and colleagues made a slab of silicone rubber 35mm thick, perforated with rows of holes alternating between 7 and 10mm in diameter, so that each large hole was surrounded by four small holes, and vice versa. In their experiments, the team controlled the stiffness in one direction within the sheet (call it y) by squeezing, or “confining,” the sheet by a carefully measured amount in the other direction ( x). For a fixed x confinement, they measured the relationship between force (stress) and deformation (strain) in the y direction. They showed that the shape of this curve was strongly affected by the degree of confinement.

In the team’s experiment, as the y force slowly squeezed the sheet, the large holes flattened along either the x or the y direction, and the interspersed, small holes flattened along the perpendicular direction. As the y squeezing increased, the orientation of this flattening could switch, sometimes abruptly, from x to y or y to x, which altered the stiffness. Following standard practice, after reaching the most squeezed state in the y direction, the team ran the process in reverse, slowly releasing the pressure, to see if the stress-strain curve would look the same in both directions.

The researchers found four kinds of behavior. With little or no x confinement, the amount of deformation in the y direction increased smoothly with the applied force. For greater confinement, a kink developed in the stress-strain curve, making it nonlinear. With still more confinement, the curve showed “hysteresis,” an even more pronounced nonlinear behavior where the forward and reverse curves don’t match. In this case, the material could absorb and dissipate energy (by generating a bit of heat), rather than simply storing it like a spring. Finally, for still more confinement in the x direction, the curve became smooth again. Florijn and colleagues saw the same behavior in numerical simulations of a two-dimensional elastic sheet with the same pattern of holes.

Florijn says one could imagine using the material to make the feet of a robot “change from more bouncy to more dissipative, depending on the terrain.” Or one could build a car bumper that “can dissipate a lot of energy during impact but afterwards can easily be brought back to its original shape and strength.”

Martin Wegener of the Karlsruhe Institute of Technology in Germany, who has developed other metamaterial structures, calls the work a “step forward in controlling mechanical metamaterials.” Previous work, he says, has focused mainly on linear properties, as in a simple spring. Here, in contrast, the material can behave nonlinearly—making possible applications such as shock absorption. “I expect that the paper will stimulate further work” on similar structures, says Wegener.

This research is published in Physical Review Letters.

–Philip Ball

Philip Ball is a freelance science writer in London. His latest book is How Life Works (Picador, 2024).

References

- P. Wang, F. Casadei, S. Shan, J. C. Weaver, and K. Bertoldi, “Harnessing Buckling to Design Tunable Locally Resonant Acoustic Metamaterials,” Phys. Rev. Lett. 113, 014301 (2014)

- T. Bückmann, M. Thiel, M. Kadic, R. Schittny, and M. Wegener, “An Elasto-mechanical Unfeelability Cloak Made of Pentamode Metamaterials,” Nature Commun. 5, (2014)