Thin-film Peeling is Not Always Smooth

A gecko detaching its foot from a wall is a process with surprising complexity at the nanoscale. Researchers writing in Physical Review E found in a theoretical analysis that nanoscale surface bumps can cause a film to peel off in a series of discrete steps, thanks to tiny fluctuations in the film-surface attraction. The work suggests that films can detach from surfaces more easily than previous models predicted, and it could help explain how gecko feet detach from walls and ceilings. The result could also influence how researchers peel away sheets of graphene and other atomically thin objects in the lab.

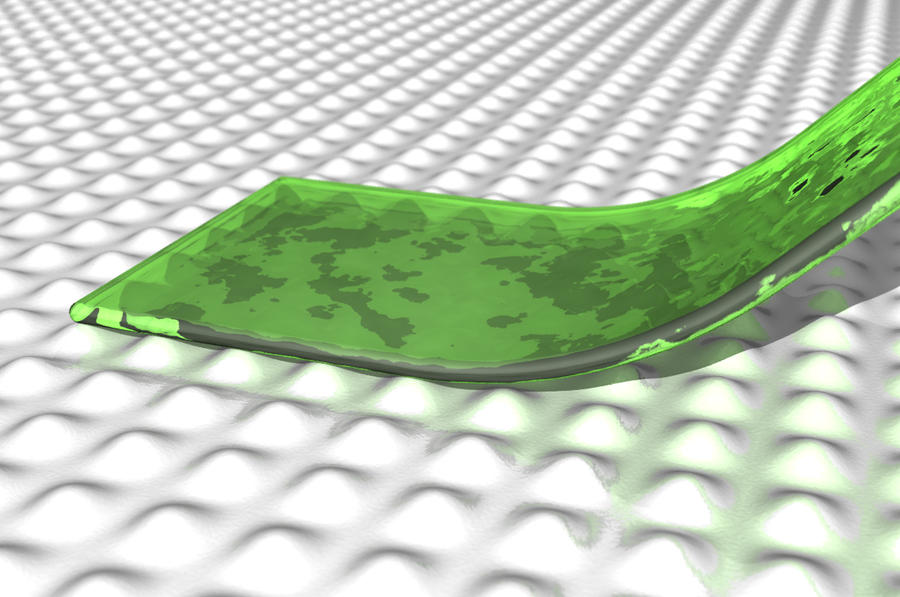

When a thin film comes within a few nanometers of a surface, the van der Waals attraction kicks in and pulls the film toward the surface. Geckos take advantage of this attraction to walk on smooth vertical walls and ceilings using millions of tiny foot extensions called spatulae.

A theory explaining how gecko spatulae and other thin films adhere to perfectly smooth surfaces has existed for several decades. More recent work has extended the explanation to surfaces with micrometer- and nanometer-sized bumps and grooves. Researchers have also examined the process of peeling a film off of a bumpy surface, which could lead to the development of adhesive tape that mimics gecko feet, for example.

Existing peel-off theories use a single, fixed value for the van der Waals force. But Stefan Lindström of Linköping University in Sweden and his colleagues thought that accounting for the thermally fluctuating nature of the force at the nanoscale might lead to important differences in the predicted peel-off behavior. The researchers analyzed a thin film adhering via a fluctuating van der Waals force to a surface with regularly spaced, nanometer-high bumps. The random thermal fluctuations that the team included are known to increase the failure rate for van der Waals adhesion.

The researchers considered a range of values for the film’s flexibility but focused mainly on an intermediate value that turned out to match the gecko’s spatulae. Such a semiflexible film would contact the surface only at the tops of the bumps, so the team assumed that the van der Waals attraction, which is extremely short range, would only be significant at those locations.

In analyzing the peel-off process, the researchers found that fluctuations in the van der Waals attraction at the contact points in front of the advancing film-surface “crack” were critical. These fluctuations could cause the film and surface to fully separate, in effect amplifying the peeling force’s effect. So a tiny crack could open into a wider one through a series of fluctuation-induced detachments between the film and individual bumps in the surface. If this process were to repeat for millions of spatulae, a gecko could fall off a wall or ceiling, Lindström says.

This connection between nanoscale thermal fluctuations and the peel-off process is new, says Lindström. “This improves on previous models,” he says. “They are not wrong, of course, but this adds an additional effect you see because of the [nanometer] scale.”

The model explains why experimental peel-off rates can vary even for identical films adhering to identical surfaces, says Joris Sprakel of Wageningen University in the Netherlands. Such results did not jibe with previous peel-off models that neglected thermal fluctuations, Sprakel says. “The interesting thing is that such small, random, and seemingly insignificant events at the nanoscale can have such a large influence on processes occurring on macroscopic length scales,” such as a gecko’s foot pad adhering to a wall.

But chemical engineer Manoj Chaudhury of Lehigh University in Bethlehem, Pennsylvania, says that real-world bumps encountered by a gecko are closer to micrometers in size, so further work may be needed to apply the team’s model in a practical way. But Lindström says his model could apply even to surfaces with micrometer-sized bumps, because any real-world material will have some roughness at the nanoscale as well.

The team’s model could also help researchers design new laboratory processes for separating films from surfaces, says Lindström. For instance, researchers often grow atomically thin graphene sheets on a surface and then peel them off, but if the peel-off force is too strong, the sheet may rip. The team’s model suggests that a smaller force than previously thought may be sufficient to remove such a film.

–Gabriel Popkin

Gabriel Popkin is a freelance science writer in Washington, DC.