Two Modes of Balloon Bursting Revealed

When a balloon pops, how many pieces does it break into? A study using high-speed video shows that there are two different bursting modes—a single tear and several tears—and explains why they exist. Researchers inflated sheets of rubber into balloon shapes in a reproducible way and popped them. According to their video data, it all depends on the stress in the rubber sheet, determined by the pressure inside the balloon. At low pressures, a single crack can dissipate the stress, but above a threshold pressure, multiple cracks are required.

It was sheer curiosity that led Sébastien Moulinet of the Ecole Normale Supérieure (ENS) in Paris to think about this problem. “I started to get interested in this question after seeing an artistic photograph of an exploding balloon,” he says. “I noticed that the cracks seemed to be separated by the same distance” and that they advanced in parallel. These properties can produce a kind of “rib-cage” structure of fragments.

Moulinet wondered what causes this pattern and why the breakup sometimes takes a simpler form. To answer these questions, he and ENS colleague Mokhtar Adda-Bedia studied a more controllable system than a toy balloon. They used a thin, flat, latex rubber sheet of uniform thickness, clamped over a 5-cm-wide hole through which it could be inflated, like a soap film on a child's bubble-blowing wand. At a fixed distance in front of the hole, the researchers placed a sharp blade that would puncture the bubble once it reached a certain size and therefore a certain internal gas pressure. They could vary the bursting pressure simply by moving the blade closer or further away from the hole.

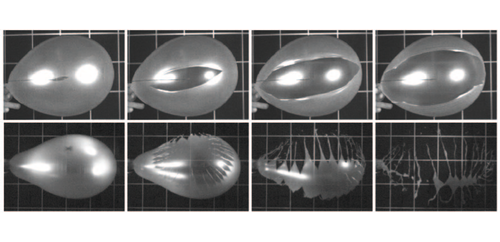

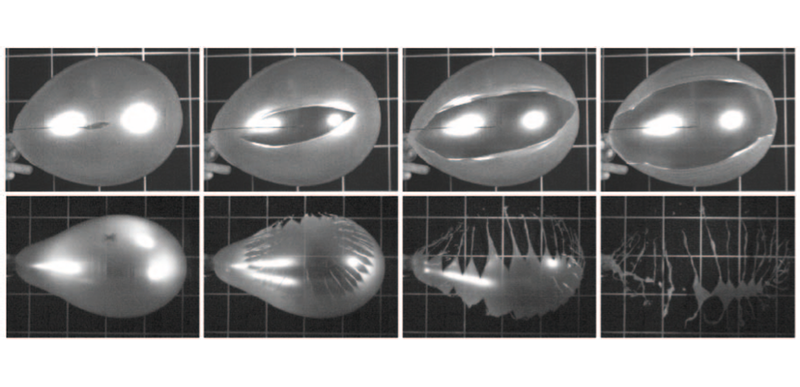

The researchers found that, for relatively low pressures, the bubble split with a single crack that spread from the puncture point like an ever widening mouth. But above a critical pressure, this fracture mode changed to one in which several cracks spread radially from the puncture point. Inspecting the tears in the rubber remnant from such bursts, Moulinet and Adda-Bedia found a tree-like branching pattern (which was not obvious in the video recordings). The higher the initial pressure, the more branching occurred, and so the more “fingers” were generated.

Moulinet and Adda-Bedia found that the key parameter controlling the bursting is not the internal pressure but the stress in the rubber membrane, which depends not only on the pressure but also on the thickness and curvature of the membrane. The higher this stress, the faster the crack moves to dissipate the stress. But there's a limit to the speed a crack can travel through rubber, the video images showed. When the stress goes above this threshold, the researchers found, the only way the crack can dissipate stress faster is to split into more cracks.

“The higher the stress, the more elastic energy is stored in the balloon, and then the more numerous the fractures need to be to release the stored energy,” says Moulinet. For the shape explored by the researchers—a bubble with a wide neck generated from a flat sheet and punctured at its apex—the branching crack produces a kind of many-armed, octopus-like remnant, instead of the “rib cage” pattern seen in typical spheroidal balloons.

The work “adds quite a bit to what we know about fragmentation,” says Jay Fineberg of the Hebrew University of Jerusalem, an expert in fracture dynamics. He says that most previous studies in other fragmenting systems have observed the growth of separate cracks that intersect and merge. In this case, the branching patterns show that cracks become unstable as they propagate, which causes them to split into multiple cracks. He thinks that this illustrates a new mode of breakup.

Michael Marder of the University of Texas at Austin says that after publishing research on rubber fracture some years ago, he was sent many “rubber octopuses” by park rangers—the remains of burst balloons found in trees. He found the shapes puzzling and is intrigued that these new experiments seem to explain them.

This research is published in Physical Review Letters.

–Philip Ball

Philip Ball is a freelance science writer in London. His latest book is How Life Works (Picador, 2024).