Shaking Cleans Nanoscale Surface

Molecules ordinarily diffuse very slowly within the nanoscale space between two solid surfaces that are in contact, but researchers now show that vibrating one of the surfaces can make such motion millions of times faster. The team used computer simulations and experiments with graphite surfaces to demonstrate the effect. In future microscopic mechanical devices, the researchers suggest, the effect might be exploited to help clean the spaces between sliding surfaces, thereby greatly reducing both friction and the wear on parts.

Researchers already know that small vibrations or oscillating forces can often reduce the friction between two surfaces [1, 2]. Vibrations dislodge the surfaces if they get momentarily stuck together by molecular contacts, allowing them to slide more easily. Michael Urbakh of Tel Aviv University in Israel and his colleagues suspected that a similar technique might also dislodge molecules and allow them to diffuse across a surface more easily.

They developed a mathematical model for the diffusive movement of molecules trapped in a small gap between two surfaces, which is a common situation of interest for micromachines. In the model, there are many molecules in the gap, and they move under the action of a variety of forces, including forces tending to attach them to either surface, as well as interactions among the molecules.

Normally, the random kicks associated with surface thermal vibrations are too weak to knock them free. The model shows, however, that if one of the surfaces oscillates in the direction parallel to the interface, then molecular movement can be greatly enhanced. In simulations, they found that the diffusion coefficient for random molecular motion—a basic measure of how quickly molecules diffuse—can be boosted by 10 billion times with oscillations over a wide range of frequencies, especially higher frequencies. The diffusion boost occurs even if the surface oscillates by less than 1 micrometer in each cycle.

The effect works, the researchers say, because the oscillations help the molecules break free of attractive surface forces, allowing them to hop from point to point. “The energy barriers [for detaching from the surface] become very small during a fraction of each oscillation period,” says Urbakh.

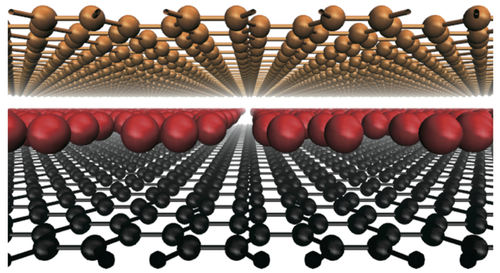

The researchers also showed in experiments that oscillations can clean surfaces. They created tiny “mesas” out of graphite—square blocks 1 micrometer high by several micrometers wide—and produced atomically clean surfaces by cleaving two of them horizontally. They then lifted the upper sections off both mesas and exposed the new surfaces to air for several minutes, so that contaminant molecules would stick. Placing the upper part of one cleaved mesa on the lower part of the second, they then used a needle-like probe to steadily slide the top piece across the bottom one while continually vibrating it horizontally, at a frequency between 5 and 1000 hertz. The probe continuously measured the force required to overcome friction during sliding.

The team found that the required force steadily decreased with time, implying an ongoing reduction in friction caused by a decrease in the number of contaminant particles present. The results suggest that the oscillations remove as many as 90% of the contaminants after only about ten cycles, the researchers report.

The team hopes that techniques of this kind will be helpful in micro- and nanomechanical devices, which can suffer from particulate contamination. These devices may have a range of future uses, such as in tiny sensors of force, mass, or biochemicals. Urbakh says that for microscopic devices, the key to solving these issues is superlubricity, a technique that allows crystalline surfaces to slide over one another with near-zero friction. But superlubricity requires extremely clean surfaces, which might need to be maintained with self-cleaning techniques.

“The result is appealing,” says Annalisa Fasolino of Radboud University in the Netherlands, because the team was able to formulate a simple mathematical model that accurately describes a real system. Since graphite surfaces lack the sharp steps and discontinuities seen in many other materials, she says that the new model could be useful for future nanomechanical devices engineered with other atomically smooth materials such as graphene.

This research is published in Physical Review X

Correction (25 August 2015): The text was revised to include the frequency range of the experiments.

–Mark Buchanan

Mark Buchanan is a freelance science writer who splits his time between Abergavenny, UK, and Notre Dame de Courson, France.

References

- M. G. Rozman, M. Urbakh, and J. Klafter, “Controlling Chaotic Frictional Forces,” Phys. Rev. E 57, 7340 (1998).

- A. Socoliuc, E. Gnecco, S. Maier, O. Pfeiffer, A. Baratoff, R. Bennewitz, and E. Meyer, “Atomic-Scale Control of Friction by Actuation of Nanometer-Sized Contacts,” Science 313, 207 (2006).