Ultrasound Cleans with a Twist

Semiconductor wafers, jewelry, and other delicate items are often cleaned by immersing them in a bath of liquid vibrated at ultrasonic frequencies, but it’s hard to measure exactly how the process works. Researchers reporting 12 August in Physical Review Letters studied a controlled bubble that resembled those that do the work in ultrasonic cleaning. The team found that as the bubble expanded and collapsed, it exerted a strong rolling force on particles stuck to a solid surface, which helps explain why the cleaning process is so effective. The team hopes that a better understanding of the process will lead to future improvements in cleaning technology.

Even a single defect on a semiconductor chip can render it useless. Molecule-scale contaminants on wafers destined to become chips can be removed chemically, but dislodging larger particles often requires mechanical force as well. Researchers think that in ultrasonic cleaning this force comes from bubbles that expand and contract with every pressure cycle, which could be a million times per second. But experimentally tracking the bubbles and the effects of the fast-moving fluid they generate has been difficult.

A team at the Nanyang Technological University in Singapore led by Claus-Dieter Ohl adapted a technique for creating a bubble where and when they wanted it. They focused a laser pulse up through a glass microscope slide into a strongly absorbing liquid dye. The laser heating caused the bottom layer of the dye to evaporate explosively, forming a hemispherical bubble at the glass surface that grew to tens of microns in radius and then collapsed, all within about 25 microseconds. The team stuck several-micron-diameter plastic beads on the slide surface and immersed them in the dye to mimic dirt particles adhering to a surface. They then recorded video of the beads’ motion in response to the bubble.

In some experiments, the researchers coated one side of every bead with gold, so they could see the beads’ rotation. The beads rolled back and forth during a single cycle of the bubble’s expansion and contraction, some at a rate corresponding to 150,000 rotations per second. This rapid rotation implies a large twisting force (torque) on the beads. The torque arises because the beads rest partially in a thin, stationary layer of fluid at the glass surface and partially in the fluid above, which moves rapidly in response to the bubble. “The rotation is a very clear indication that this boundary layer is important,” says Ohl. Similarly, in ultrasonic cleaning, a dirt particle stuck to the surface will extend partly out of the boundary layer and feel a large torque that can break its connection to the surface.

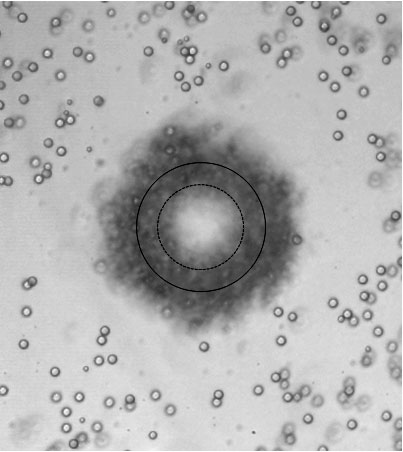

The quiescent boundary layer also affects the overall forces on detached particles, according to the team’s experiments and calculations. Particles that start close to the bubble are pushed rapidly away as the bubble expands, and their inertia keeps them from completely returning to where they started as it collapses. More distant particles, however, are pulled a little closer during each cycle of expansion and contraction by a complex flow pattern near the glass surface. As a result, repeating the pulses gathered particles into a roughly 60-micron-diameter ring around the bubble, where the attraction and repulsion cancelled out.

“This is one of the first experiments to visualize a particle around a rapidly expanding and contracting bubble,” says Ho-Young Kim of Seoul National University in South Korea. Although there may be important differences with the smaller, continuously oscillating ultrasound bubbles used in cleaning, he says, the combination of controlled bubbles with a two-dimensional geometry for visualizing the particle motion is “very clever.”

–Don Monroe

Don Monroe is a freelance science writer in Murray Hill, New Jersey.