Dense Suspensions Spread Best

How well wet paint and other liquid-particle suspensions coat a surface depends on the surface’s wettability and the liquid’s viscosity. These properties must therefore be carefully tuned in applications that require an evenly thick liquid coating, such as spray paints for cars and inkjet printing. Writing in Physical Review Letters, Heinrich Jaeger, Wendy Zhang, and their colleagues at the University of Chicago, Illinois, show that dense suspensions, which contain more particles than liquid, could behave as “universal” coatings that spread out evenly on many surfaces.

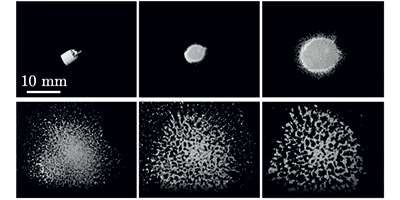

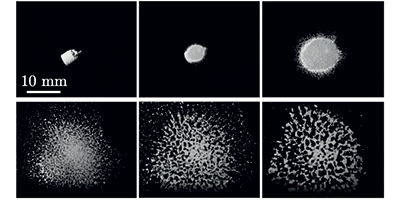

The researchers prepared suspensions of -micrometer-sized ceramic spheres in either water or oil and released drops of the liquids from a height of ~ meters onto a flat, solid surface. On impact, the drops flattened, initially spreading out to form one-particle-thick films across the surface. As the films continued to expand, they formed a lace-like pattern containing regions with only liquid and no particles—a pattern the authors dubbed a “splat.” Simulations and modeling showed that, under the conditions used by the researchers, the expansion was dominated by the speed of the drop on impact, while properties like surface tension, viscous drag, and surface wetting had little effect on the impact dynamics and the resulting splat pattern.

The regime of impact and spreading parameters studied by Jaeger, Zhang and their colleagues, should also be relevant to splats containing nanoscale particles. For applications that do not require a uniform film on the particle level, dense suspensions could provide a convenient way to quickly and robustly deliver thin coatings. – Katherine Wright