So Many Cracks, So Little Time

The fragmentation of a shrinking solid occurs in many natural and industrial processes, such as the cooling of magma and the drying of ceramic glazes. The ability to predict the fragmentation dynamics of a material enables precise control over a material’s response to rapid cooling, which could benefit many applications. Now, a team of scientists led by Thomas Séon at the Jean Le Rond d’Alembert Institute, France, has theoretically and experimentally studied the fragmentation patterns of drops of water that freeze as they impact a cold surface.

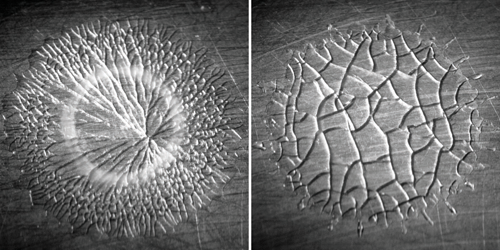

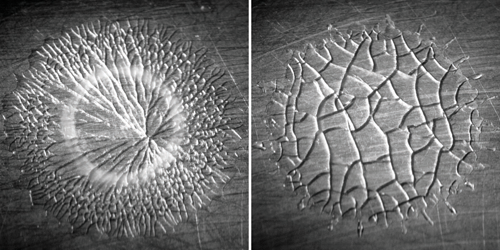

Séon and his team dripped water onto a stainless-steel surface held at temperatures between and and observed the droplet solidification process using a high-speed camera. The contact between the droplets and the steel limited the droplets’ ability to contract as they froze, and the resulting mechanical stresses often caused the frozen droplets to fracture within a few milliseconds. Séon and his colleagues observed that the structures of the surfaces fell into one of three regimes: a smooth face with no fractures, many small fractures emanating from a single nucleation point, and hierarchical fractures in which fewer, larger cracks occurred at roughly right angles to one another.

The researchers used classical scaling laws for fracturing to explain the appearance of these three regimes. Their calculations revealed that the regimes ought to occur as a function of the temperature of the steel surface. Séon and his co-workers verified this trend in their experiments, explaining that it arises from the balance between the thickness of the frozen puddle, which decreases with surface temperatures, and the minimum size of a fragment.

This research is published in Physical Review Letters.

–Katherine Kornei

Katherine Kornei is a freelance science writer based in Portland, Oregon.