Relaxation is a Two-Step Process for Metallic Glasses

For most of us, glass is the clear material that’s used to make windows and wine bottles. But glasses, which lack the conditions necessary to reach thermal equilibrium, come in many forms. They can be transparent or opaque, metallic or insulating, and their fundamental building blocks can be as small as atoms or as large as polymers. Finding similar behaviors in different types of glasses could lead to a better understanding of the materials, and potentially to an overarching theory for them. A team led by Weihua Wang of the Chinese Academy of Sciences in Beijing has made such a connection. They report the first evidence that a strained metallic glass relieves mechanical stress, or “relaxes,” via two steps [1], one fast and one slow—a two-step relaxation process that has so far only been observed in “soft” glasses like colloids. The fact that the process also occurs in a rigid, or “hard,” glass like a metal suggests that it may be a universal feature of glassy systems. In general, the results provide a fuller picture of the dynamics of the out-of-equilibrium nature of glasses, which is poorly understood.

Metallic glasses are alloys with amorphous atomic structures. They are obtained by rapidly cooling, or “quenching,” the alloy from its high-temperature, liquid phase to below its glass-transition temperature. The quenched metal’s structure is out of equilibrium from its preferred crystalline form. As such, the structure will spontaneously start to evolve very slowly over time, a process known as aging, which can last for a much longer time than any laboratory experiment. The strength and resistance to corrosion of metallic glasses often exceeds that of crystalline metals, making them of interest for certain applications. But they are also model glassy systems because of their simple atomic structure, which can be described as a dense random packing of hard spheres.

Metallic glasses and other rigid amorphous solids respond to external stimuli with a broad distribution of relaxation times, from picoseconds to over hours or days. In addition, their response to any external stimulus depends on the length of time since they started to age. However, developing a deep understanding of the interplay between aging and relaxation remains a challenge for condensed-matter physics.

The experiments by Wang and colleagues address this interplay. The team focused on three common metallic glasses, Zr44Ti11Cu10Ni10Be25, Zr50Cu40Al10, and La55Ni20Al25. They quenched the compounds in flat-ribbon-shaped molds to below their glass-transition temperatures, which in this case lie between 400 and 700 K. After a certain “waiting time,” the team subjected each ribbon to a sudden elongation, or strain, of a few percent and measured the corresponding stress within the ribbon over time, observing that it decayed in two steps. The first was steep, with a falloff that occurred within tens of seconds and was faster than exponential in time. The second step was more gradual, occurring over minutes to several hours and was slower than exponential in time—an indication of cooperative motion of the atoms in the alloy. Unlike the first step, the second step only appeared at temperatures well below the glass-transition temperature and for strains that were induced after waiting for a long time (3 hours).

The gradual relaxation that Wang and colleagues observed in the second step is well known from experiments with glasses [2]. The fast relaxation step, in contrast, is a new finding for metallic glasses and for rigid glasses in general. Indeed, it was only by performing their measurements on the three materials over a wide range of temperatures and at waiting times that varied from minutes to over a week that the team was able to distinguish the two steps.

Prior to the work by Wang’s group, hints of a faster than exponential relaxation in metallic glasses had shown up in measurements of the materials’ atomic correlation function [3], which describes the average position of an atom with respect to its neighbors. Researchers have attributed this fast process in metallic glasses to the presence of internal stresses or defects in the atomic arrangement, both of which can be created during a quench. Indeed, a mesoscopic model [4] that describes stress relaxation in a thermally activated elastic glass predicts a faster than exponential decay, followed by a more gradual decay. Similar behavior has been measured in glassy polymers, whose enthalpy has been found to relax in two steps [5].

Where fast relaxation during aging is well established is in out-of-equilibrium soft materials [6]. One example is a colloidal suspension of clay particles in water [7, 8]. X-ray photon correlation and light-scattering measurements that are sensitive to density correlations in the suspensions have revealed a fast decay followed by a long-time aging regime. The length- and time-scale dependences of these two relaxation processes indicate that the fast one arises from the uncorrelated motion of individual clay particles, while the slow one originates from correlated rearrangements of all of the particles. In addition, measurements of the mechanical response of the materials have found that clay suspensions exhibit a two-step relaxation process like that observed in metallic glasses by the Wang group [9].

Metallic glasses are composed of atomic units that interact via short-range potentials, while colloids consist of nanometer- or micrometer-sized particles with long-range, or “soft,” potentials. That these two vastly different prototypical glass-forming systems relax in a similar way is a tangible clue that relaxation in aging glasses follows a universal pattern. The correspondence also suggests that colloidal glasses could be used as a “proxy” for metallic glasses and potentially for other types of glasses. This possibility could prove useful: in colloids the size of the particles and the type of interaction between them (attractive or repulsive), as well as the ways in which the colloid is driven out of equilibrium, can all be adjusted to suit the needs of the experiment.

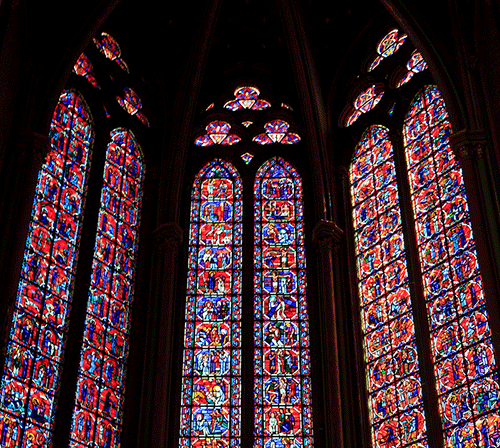

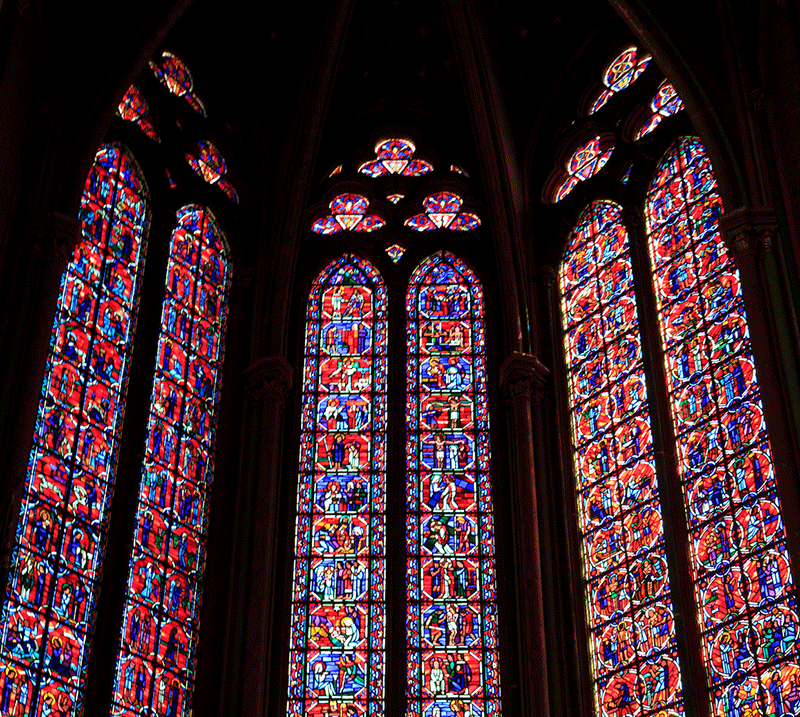

In certain glassy systems, like the silica-based glass in a wine bottle or in cathedral windows, the process of restoring equilibrium takes practically forever (Fig. 1). The work by Wang and colleagues indicates that metallic glasses provide a useful system for studying equilibrium restoration on more experimentally friendly time scales. The results might also help researchers improve the functionality and stability of rigid glasses, whose tendency to relax under strain or deformation can be a downside. Specifically, the time scale for the slow stress-relaxation step could be made to exceed the material’s “working” lifetime by using the material after a certain waiting time or at temperatures much lower than the glass transition. In addition, the findings indicate that, at short time scales, some relaxation in a glass is always “active,” which must be accounted for to ensure that the material’s mechanical properties are stable.

This research is published in Physical Review Letters.

References

- P. Luo, P. Wen, H. Y. Bai, B. Ruta, and W. H. Wang, “Relaxation Decoupling in Metallic Glasses at Low Temperatures,” Phys. Rev. Lett. 118, 225901 (2017).

- R. C. Welch et al., “Dynamics of Glass Relaxation at Room Temperature,” Phys. Rev. Lett. 110, 265901 (2013).

- B. Ruta et al., “Atomic-Scale Relaxation Dynamics and Aging in a Metallic Glass Probed by X-Ray Photon Correlation Spectroscopy,” Phys. Rev. Lett. 109, 165701 (2012).

- E. E. Ferrero, K. Martens, and J.-L. Barrat, “Relaxation in Yield Stress Systems through Elastically Interacting Activated Events,” Phys. Rev. Lett. 113, 248301 (2014).

- D. Cangialosi, V. M. Boucher, A. Alegría, and J. Colmenero, “Direct Evidence of Two Equilibration Mechanisms in Glassy Polymers,” Phys. Rev. Lett. 111, 095701 (2013).

- L. Cipelletti et al., “Universal Non-Diffusive Slow Dynamics in Aging Soft Matter,” Faraday Discuss. 123, 237 (2002).

- R. Angelini, L. Zulian, A. Fluerasu, A. Madsen, G. Ruocco, and B. Ruzicka, “Dichotomic Aging Behaviour in a Colloidal Glass,” Soft Matter 9, 10955 (2013).

- F. A. de Melo Marques, R. Angelini, E. Zaccarelli, B. Farago, B. Ruta, G. Ruocco, and B. Ruzicka, “Structural and Microscopic Relaxations in a Colloidal Glass,” Soft Matter 11, 466 (2015).

- R. Bandyopadhyay, P. H. Mohan, and Y. M. Joshi, “Stress Relaxation in Aging Soft Colloidal Glasses,” Soft Matter 6, 1462 (2010).