Stitching Together a Knit Theory

Pulling on a knitted scarf can stretch it to twice its length, even though the thread it’s knitted from hardly elongates. Knitting is a timeworn craft, at least a thousand years old, but no satisfactory account of the mechanics of its stretchiness exists. New theoretical work describes how individual stitches in a knitted fabric respond to tension. The model correctly predicts how a nylon knit stretches, and it could be helpful in designing “smart materials” that can spontaneously fold into a specific shape.

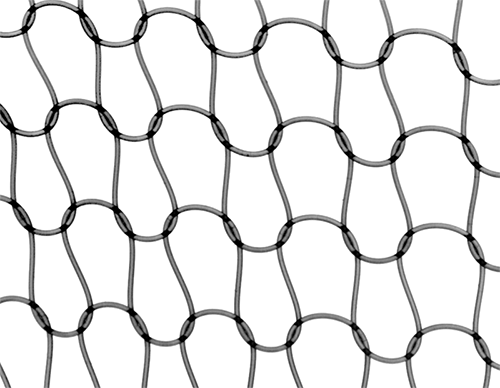

In contrast to woven fabrics, which are made of multiple threads that cross each other, a knitted fabric consists of a single thread that loops back and forth on itself to form an interlocking network of stitches. Although individual stitches—the open loops in the fabric—maintain their identity when a knitted fabric is deformed, the thread itself can slide from one stitch into a neighbor. This is why knits are so flexible and why they can easily drape over other objects. Indeed, engineers are using knits as highly deformable scaffolds that can be combined with hardening resins to form composite materials.

Frédéric Lechenault of the École Normale Supérieure in Paris began thinking about the physics of knitting three years ago, when his first child was born. The baby’s knitted booties and blankets were highly stretchable, “and yet, paradoxically, the individual threads don’t stretch much at all,” Lechenault says. Previous models of knitted materials have assumed that the fabric responds uniformly to stretching, neglecting the fact that the behavior of each stitch depends on its location in the fabric. Lechenault and his colleagues sought instead to develop a knit model starting with the fundamental mechanics of the interlocking threads.

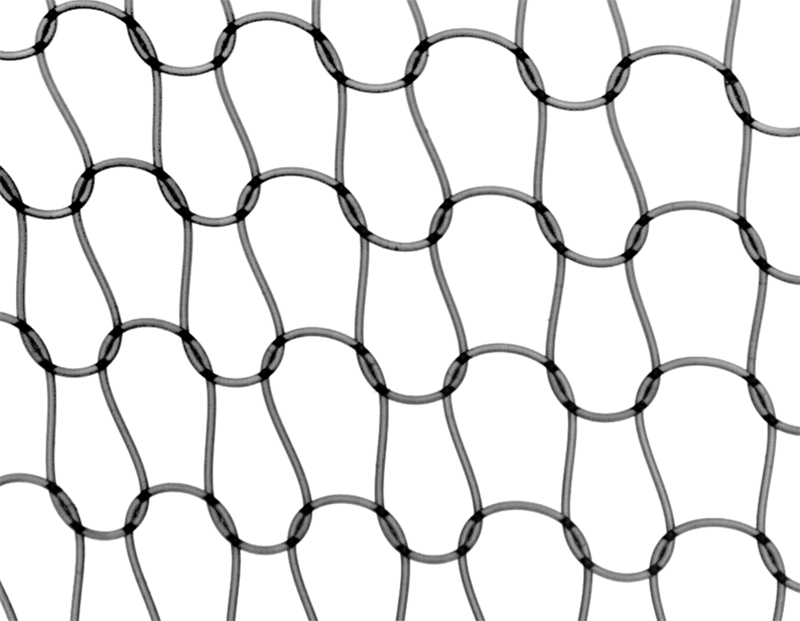

The researchers began by performing some simple stretching experiments on a 20-cm-wide knitted fabric made from thin nylon fishing line. The knit consisted of a grid of 51 by 51 stitches in a stockinette configuration, a common knitting pattern. The researchers clamped the material at both ends and used a video camera to record the changing position and shape of each stitch in the fabric when it was stretched.

The stitches tended to move in straight lines. Those at the sides moved mostly horizontally, while those in the middle moved mostly vertically. The stitches also deformed, typically becoming elongated and tilting away from the vertical. Overall, the fabric took on a curved, hourglass shape similar to what is often observed in solid elastic materials, such as a rubber sheet, when stretched.

Guided by these observations, the researchers set up a model that treats each stitch as a four-sided “cell” corresponding to a visible loop in the fabric. With the fabric at rest, each cell has the same shape, but as tension is applied, the model predicts how the shape of a given stitch would change as a consequence of its position in the grid and its relation to its neighbors. The fundamental basis of the model is that stitches move so as to minimize the energy associated with bending the thread from its initial configuration. The researchers specify that the thread slides and bends but doesn’t stretch. With these assumptions, the team calculates how each stitch would respond when the fabric is stretched and what the resulting shape of the fabric would be. Their predictions matched their observations of the nylon fabric.

The stitch-based model, the researchers say, reduces the complex pattern of a knit to a few simple equations that can easily be adapted to different stitch patterns. They add that the model can also be used to explore how knitted fabrics move in three dimensions and suggest that it could help in developing self-folding fabrics. These smart materials would be knitted to have a specific curved shape that they would adopt when triggered by heating or by a mechanical stimulus.

Mechanical engineer Pedro Reis of the Swiss Federal Institute of Technology in Lausanne, Switzerland, likes the model especially because it captures the position dependence of stitch deformation. He adds that the theoretical framework developed by Lechenault and co-workers should be relevant to a broad range of fabrics as well as mechanical metamaterials. “It is time for physicists to get knitting,” he says.

This research is published in Physical Review X.

–Michael Schirber

Michael Schirber is a Corresponding Editor for Physics Magazine based in Lyon, France.

More Information

The History of Hand Knitting, from the Victoria and Albert Museum