X-Ray Movie Reveals Origin of Metal Splashing

Metal 3D printing uses a laser to fuse metal powder particles into intricate objects, but the beam often creates flying blobs of molten metal that can lead to manufacturing defects. The cause of this “metal spatter” was poorly understood, but a new x-ray movie has captured the process in detail. Researchers observed the formation of tiny liquid bumps on the molten metal surface that play a central role in producing the airborne droplets. The team’s work may help in optimizing laser conditions to reduce spattering.

In one version of metal 3D-printing, called laser powder bed fusion, a layer of metal powder is spread across a solid surface. At specific locations, a scanning laser beam strikes the layer, causing the powder and the surface beneath to temporarily melt into a small puddle. As the laser traces out a pattern, the puddles in its wake solidify, forming one layer in the desired object. The process is repeated with more powder spread over the top to form the next layer. This technique and similar ones produce a wide range of products, such as lightweight airplane parts and custom hearing aids. But one problem that has limited 3D printing is spattering. Ejected metal droplets often land in the powder and re-solidify, which can lead to defects within the final product, explains Tao Sun from Argonne National Laboratory in Illinois.

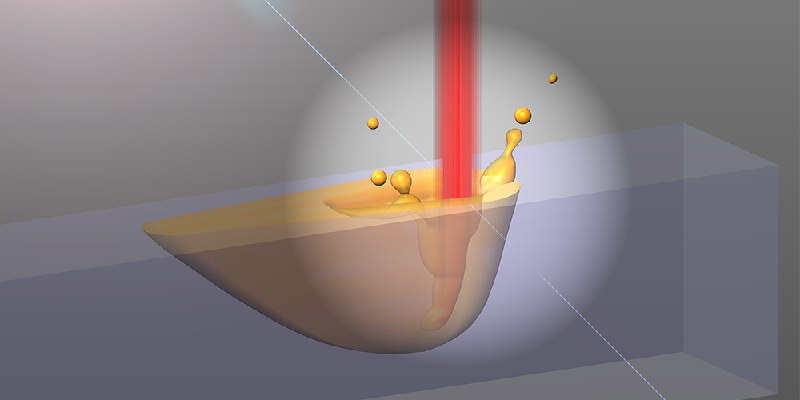

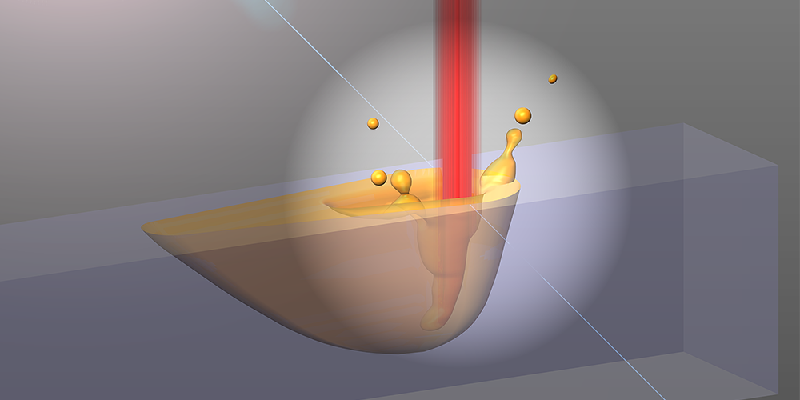

To address the problem, researchers have tried to model the mechanisms that produce metal droplets. The current understanding is that spattering arises from the “keyhole”—a narrow and deep depression in the molten puddle surface, produced by the laser as it vaporizes molten metal at the laser-metal contact point. The assumption is that small droplets of liquid metal are cleaved off of the keyhole rim and are then pushed upward by the pressure of vaporized metal streaming out of the keyhole. However, researchers have identified some droplets that move too fast (up to 50 meters per second) to have been accelerated by the typical pressure from laser vaporization.

Sun and his colleagues have now explained the fast-moving droplets. For their experiments, they installed a 3D printing system in one of the beamlines of Argonne’s Advance Photon Source (APS). It is difficult to isolate spatter from a powder bed, so the researchers observed the laser-metal interaction on a bare sheet of titanium alloy, a material that is commonly used to make parts for the aerospace industry. Using x-ray pulses from the APS, the team recorded images of the keyhole region inside the alloy with micrometer spatial resolution and at millions of frames per second.

The high-speed movies revealed that tiny bumps form regularly on the wall of the keyhole. Normally, these bumps are pushed down by the laser’s radiation pressure, but in certain cases, vapor pressure and radiation pressure combine to hold a bump in place so that “it becomes elongated like a tongue,” Sun says. The tongue-shaped feature eventually extends from one wall to the other, forming a momentary lid across the keyhole. As the tongue absorbs laser energy, it rapidly heats up and explodes, creating a burst of vapor pressure that blasts out several droplets from the keyhole rim.

Having uncovered the origin of high-speed metal blobs, Sun and his collaborators considered ways to prevent their formation. One idea—already used in some laser welding applications—is to blow a non-reactive gas (like argon) at the laser impact site. The gas could keep the keyhole open and prevent bumps from reaching the tongue stage. However, such a gas would be impractical in 3D printing, as it would disturb the powder bed, Sun says. Another option is to alter the shape of the laser beam, or use multiple beams, with the goal of widening the keyhole or lessening the thermal gradients around the keyhole—either of which should make tongue formation less likely.

“Probably the greatest promise of this study and future work on observing different types of spatter is that this knowledge could be used to improve the control of [3D printing] machines,” says mechanical engineer Aaron Stebner from the Colorado School of Mines in Golden. For example, Stebner says that monitoring the spatter above a powder bed could be used to infer the formation of defects and their types. “This work provides the key insight as to the nature of spatter as it forms from keyhole defects.”

This research is published in Physical Review X.

–Michael Schirber

Michael Schirber is a Corresponding Editor for Physics Magazine based in Lyon, France.