Simulations Unravel Fibers’ Twisted Topology

Future generations of robots and prosthetic devices will require compact artificial muscles that are powerful and efficient. One way to make such muscles is to twist elastic fibers so that they coil up and shorten in response to a stimulus such as temperature, mimicking the contraction of the real thing. Now, Lakshminarayanan Mahadevan at Harvard University and colleagues have quantified this process by simulating how soft elastic filaments respond when they are strongly stretched and twisted.

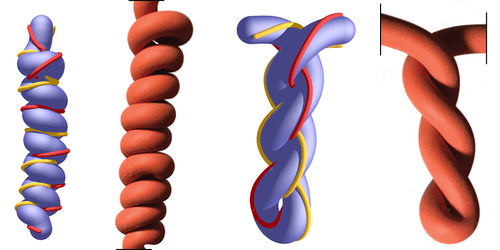

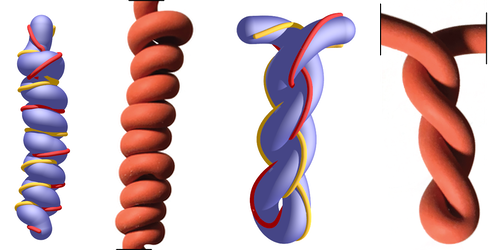

Elastic filaments accommodate twisting forces by contorting themselves into a range of configurations. Though the number of possible arrangements might appear endless, for a filament that is anchored at each end—like a muscle—the shapes are actually made up of a combination of three basic forms: The filament stays straight, or it forms a simple corkscrew-like coil called a solenoid, or it becomes a DNA-like loop of intertwined helices called a plectoneme.

In their simulations, the researchers modeled different force regimes to come up with a phase diagram that relates a filament’s final configuration to the forces applied to it during twisting. The team showed that, under strong tension (due to stretching when it’s anchored) and weak twisting, the filament tends to remain straight. Strong twisting without much tension yields plectonemes, and when the filament is strongly stretched and twisted, it adopts a solenoidal form. Near the triple boundary where the phase spaces of the three shapes meet, the filament exhibits a complex combination of all three.

The researchers hope that their results will lead to better designed artificial muscles. Their insights might also be relevant in understanding how polymers can deform when twisted and how magnetic field lines get their topology and geometry.

This research is published in Physical Review Letters.

–Marric Stephens

Marric Stephens is a freelance science writer based in Bristol, UK.