Some Granular Columns Weigh Too Much

In a silo full of grain, the walls support some of the grain’s weight, so the measured weight is less than the grain’s true weight. Experiments and simulations of an analogous, lab-scale system now show that in some situations, the measured weight may instead exceed the particles’ total weight. This effect applies only to narrow cylinders—not real silos—but the results reveal new phenomena that could be relevant for granular systems in the food, construction, and pharmaceutical industries.

Grain particles packed in a silo press against one another tightly enough that they are partially suspended, an effect that relies on friction among the particles and friction between the particles and the walls. This support reduces their apparent weight, as shown by German engineer H. A. Janssen in 1895 [1].

Experiments using model silos to check the Janssen predictions have previously shown that the filling technique affects the results. For example, you can pour the particles in as a continuous stream, or you can uniformly coat the entire circular area of the cylinder, so that the top surface remains flat during filling. The procedure has an effect on the way that particles get wedged against the walls. In 1923, a pair of physicists proposed that, in some cases, the filling protocol could cause friction at the walls to push downward against particles, rather than upward [2]. But experiments have not yet revealed such downward forces.

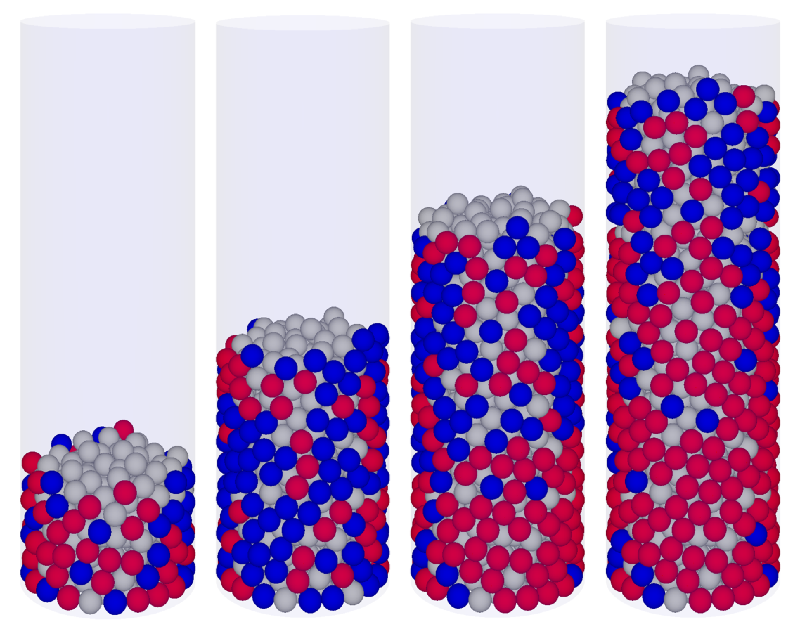

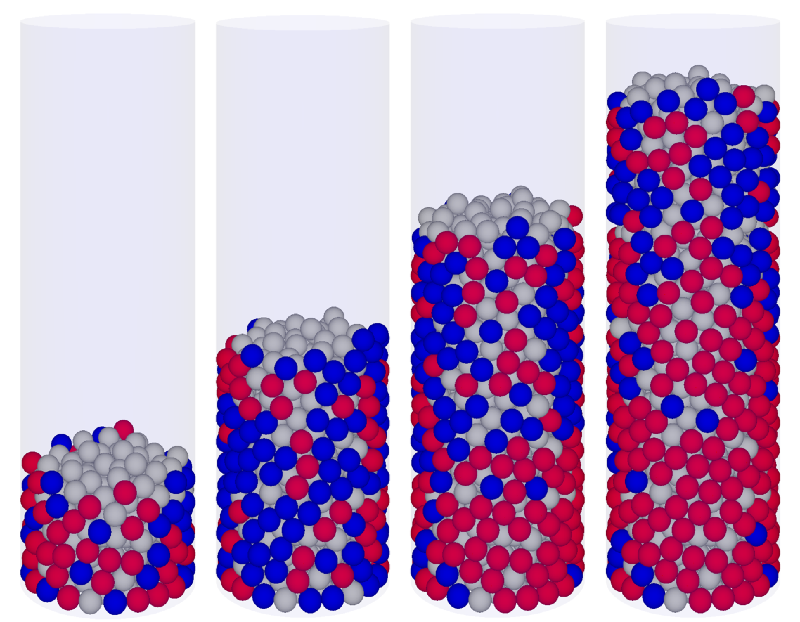

A team led by Massimo Pica Ciamarra of Nanyang Technological University, Singapore, and Alberto Fernandez-Nieves, of the Georgia Institute of Technology and the University of Barcelona, investigated the cylinder-filling process and the frictional forces that it can produce. The researchers poured 6-mm-diameter, plastic beads, a few at a time, into glass cylinders of different diameters, allowing the column of particles to settle between each new set of beads. After each addition of particles, they measured the apparent weight and the column height.

For large cylinders (diameters at least 30 times that of a single bead), as the column height increased, the apparent weight increased more slowly than the true weight, as predicted by Janssen’s model. However, for small cylinders (diameters 8–12 times that of a bead), the apparent weight at first increased more rapidly than the true weight, reaching a maximum of more than 10% above the true weight in some cases. As the column height increased further, the apparent weight increased more slowly, until it reached and then dropped below the true weight. The observed extra weight is surprising, according to the researchers, and defies explanation within currently accepted theories.

To explain their observations, Ciamarra, Fernandez-Nieves, and their colleagues performed simulations of cylinder filling in which new particles were added one at a time, at random horizontal positions, and the column was allowed to settle before each particle was added. Through their experiments and simulations, the researchers found that as each particle lands on the top surface of the column, it nudges others sideways, which causes particles at the edges to be pushed upward against the walls. These edge particles experience a downward force from the wall, thanks to friction, which leads to the increase in apparent weight—what the team calls the “reverse Janssen effect.”

The team observed the effect only for a certain range of filling heights, between about 10 and 36 times the bead diameter for the narrowest cylinder. The effect goes away for taller columns because, as filling proceeds, a particle wedged against the wall becomes buried under an increasing weight. This weight pushes the particle downward, countering the upward push from its neighbors and reducing or reversing the downward force from the wall. Eventually, enough particles become deeply buried that the walls push upward more than downward. Upward forces also become dominant when the diameter of the cylinder is larger than 30 bead diameters because, as the diameter increases, the volume—and thus the weight pushing down on each particle at the walls—increases more rapidly than the surface area.

“The effect is totally unexpected. These results constitute a significant step in [understanding] granular matter compaction,” says condensed-matter physicist Pascal Viot of Sorbonne University, Paris. He says that the work raises several questions, such as whether it is possible to switch between reverse and standard Janssen effects, which could potentially lead to a new type of vibration sensor.

This research is published in Physical Review Letters.

–Rachel Berkowitz

Rachel Berkowitz is a Corresponding Editor for Physics Magazine based in Vancouver, Canada.

References

- H. A. Janssen, Z. Verein Deutsch. Ing. 39, 1045 (1895).

- J. Shaxby and J. Evans, “On the properties of powders. The variation of pressure with depth in columns of powders,” Trans. Faraday Soc. 19, 60 (1923).