Brighter Color-Shifting Ink for 3D Printers

Catch a glimpse of a soap bubble on a sunny day and the normally transparent, hollow sphere will shimmer like a rainbow, changing color as it moves across your view. The bubble’s shifting hue comes from a phenomenon known as iridescence, where color is produced by a material’s structure rather than by pigments. Now Luoran Shang of Fudan University, China, and colleagues have developed a new iridescent ink for 3D printing that is brighter than existing ones [1]. The ink changes its color when it is heated or hydrated, something that Shang says could allow for its use in making sensors to monitor a person’s temperature or hydration level.

Most structurally colored materials are thin-film systems that get their changing hue from patterns etched into the films or particles embedded in them. When light hits one of these film systems, interference effects cause only a single color of visible light to reflect out. For a given system, this selected color changes depending on the angle with which the incoming light hits the material and the angle with which the material is viewed, leading to its shimmering behavior.

While iridescent materials have been made for decades, their use has been limited because of the traditional thin-film geometry. To widen their application, researchers have been developing bulk iridescent materials that use the inherent patterns formed by the molecules they contain to reflect and refract light. Recently, these materials started entering the 3D-printing arena, but certain challenges—including low reflection intensity and poor flow behavior—have hindered their uptake.

For their ink, Shang and her colleagues used a biological liquid crystal called hydroxypropyl cellulose (HPC), which consists of long-chain molecules that self-assemble into a spiral-staircase arrangement within an overall layered structure. The staircase’s “step heights,” which determine the wavelength of light that the material strongly reflects, can be adjusted by changing HPC’s temperature and hydration, allowing for fine-tuning of the material’s color. It’s a very versatile system for generating iridescence, Shang says.

On its own, HPC has the wrong properties for printing, so the team mixed it with gelatin and a polymer called poly(acrylamide-co-acrylic acid), or PACA. The gelatin helped the mixture flow correctly in a 3D printer, while the PACA ensured that the material maintained its shape postprinting. They also added in carbon nanotubes—broadband light absorbers—to enhance the vibrancy of the ink.

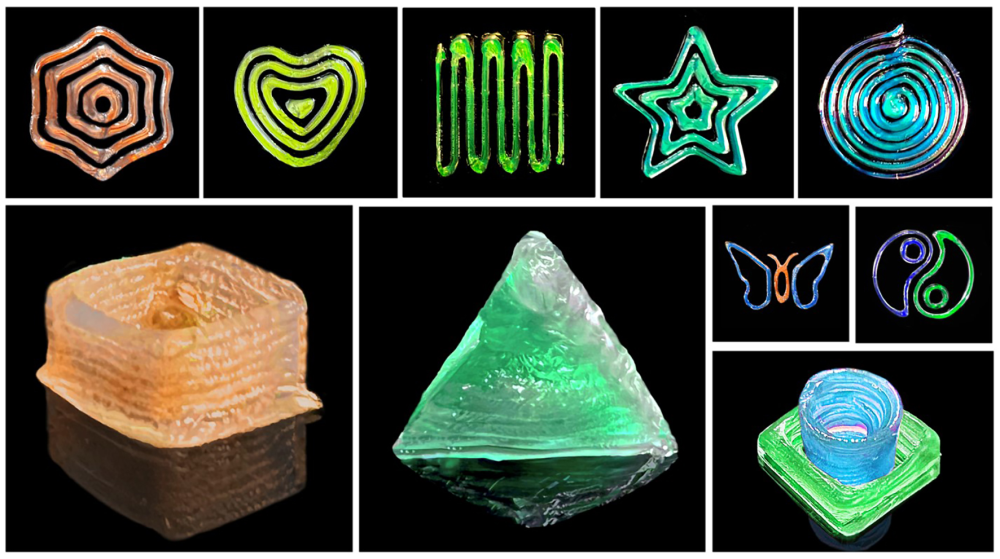

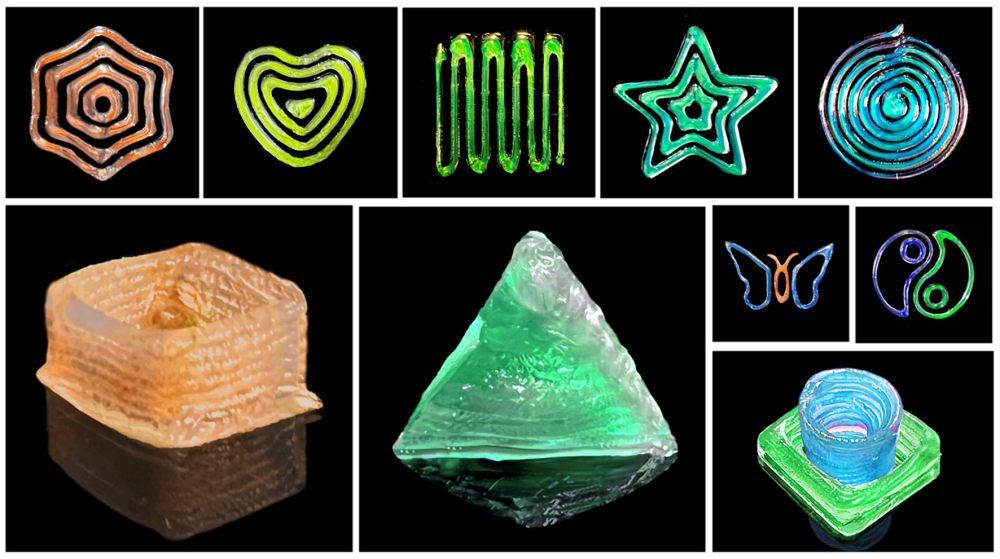

To demonstrate the 3D ink, the team printed a variety of objects, including a butterfly and a pyramid. After printing, they heated, cooled, hydrated, and dried the objects, showing that they could induce every color in the visible spectrum. By shining UV light on the objects, they were also able to polymerize PACA in the ink, permanently locking in a single hue.

Shang and her colleagues are not the first to use HPC-based materials to create an iridescent ink for 3D printing. For example, earlier this year, Silvia Vignolini and colleagues at the University of Cambridge, UK, demonstrated a similar iridescent ink [2]. In that case, the group used a different “flavor” of HPC, which assembles into spiral-staircase-containing filaments, rather than a layered structure. The group also omitted the carbon nanotubes, which reduced the color intensity of Vignolini’s ink relative to Shang’s ink.

But Vignolini thinks that her ink has other properties that might increase the likelihood of its uptake. “The HPC that we use is much more widely available in industry, while the one that [Shang] used is kind of niche,” she says. She also notes that since they only mix their HPC with water, their ink is fully biodegradable. “It’s much more sustainable.”

Because of HPC’s green credentials, Vignolini thinks it won’t be long until it starts being widely used in some form in 3D printing. “You have a material that is intrinsically colored—you don’t have to add a pigment into the plastic—and it has the bonus of being ecological,” she says. Shang is also hopeful that these materials will soon become widespread. “3D-printed, iridescent objects are really beautiful things,” she says. “That gives me hope that this advance could allow iridescent materials to make the transition from the lab to everyday life and commodities.”

–Katherine Wright

Katherine Wright is the Deputy Editor of Physics Magazine.

References

- Z. Zhang et al., “Cholesteric cellulose liquid crystal ink for three-dimensional structural coloration,” Proc. Natl. Acad. Sci. U.S.A. 119, 23 (2022).

- C.L.C. Chan et al., “3D Printing of liquid crystalline hydroxypropyl cellulose—Toward tunable and sustainable volumetric photonic structures,” Adv. Funct. Mater. 32, 2108566 (2022).