Art-Inspired Tape Is Both Strong and Weak

Ubiquitous in first-aid cabinets, it’s easy to take adhesive bandages for granted. But not all Band-Aids are created equal and finding that perfect one is tricky: too sticky and the Band-Aid may be painful to rip off, not sticky enough and it may peel off before the wound can heal. Now Michael Bartlett of Virginia Tech in Blacksburg and colleagues may have solved the bandage conundrum [1]. Using an existing adhesive tape, the team shows that carefully placed U-shaped cuts in the tape can bond the tape both strongly and weakly to a surface, with the apparent strength depending on which end of the tape the user pulls when they want to remove it.

Most of today’s adhesive tapes are either strongly bonded to a surface and thus difficult to remove or lightly bonded and easy to tear off. Researchers would like to create a tape that strongly bonds and is easy to remove. Such a tape could allow tear-free removal of Band-Aids from toddlers’ arms as well as safe packaging of shipment boxes that can be easily opened. But engineering both qualities into one material has proven difficult.

For their demonstration, Bartlett and his colleagues cut patterns into readily available adhesives, including packing tape and gloves that provide extra grip on a surface. The researchers focused their tests on cuts that contained lines of connected features shaped like the letter U, with the Us being a few cm to mm in width and height. The patterns were cut into the tape using a laser cutter.

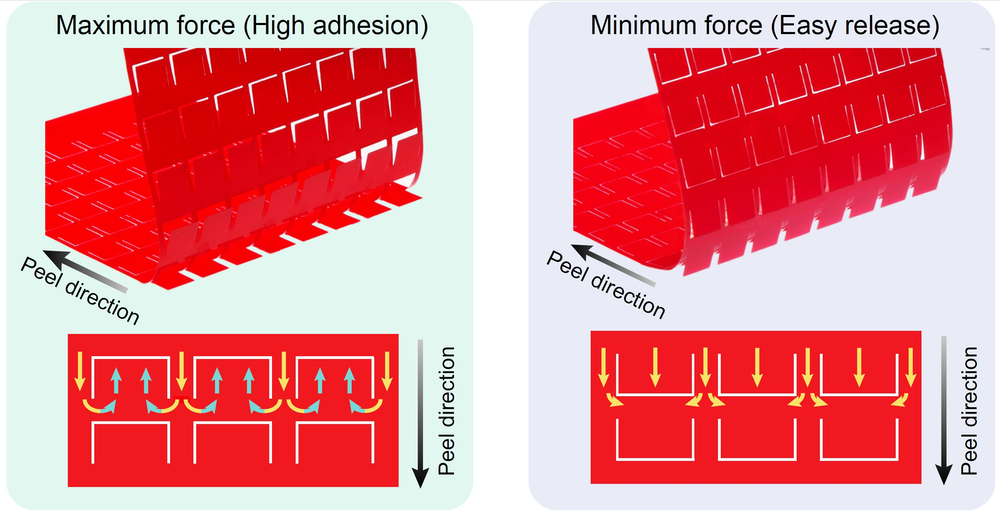

The team found that tape adhesion strongly depended on the alignment of the pulling direction with that of the Us. The strongest adhesion was found when the tape was lifted from the end that caused the tongues to peel off in the opposite direction to that in which the tape was being pulled (Video 1). In this scenario, the tongues behave in a similar manner to someone pushing down on their heels to prevent being moved, giving the tape a 60-fold increase in the strength of its cling. In contrast, when the pulling direction matched with the tongue-lifting direction, the separation was easy, and the adhesion matched that of off-the-shelf versions of the tape (Video 1).

The researchers also examined the ability of their tape to withstand heavy loads using tests that included repeatedly dropping a standard cement brick on a taped box and using the tape to hang an object on the wall. They found that boxes sealed with a length of U-patterned packing tape withstood over five impacts from a dropped brick compared to two for unpatterned packing tape. The engineered tape also secured a picture frame to a wall for a longer time: seven days for the patterned adhesive (after which the researchers removed the picture) versus 20 minutes for the off-the-shelf version.

Bartlett notes that they were able to tailor the upper strength of the adhesive by altering the height and width of the Us and the placement of the Us relative to each other and to the ends of the tape. “That opens some interesting possibilities for highly tunable adhesive films,” he says. Michal Budzik, a materials scientist at Aarhus University in Denmark agrees. The ability to easily tailor the adhesive properties of a tape without changing its chemistry will “undoubtedly be influential,” he says. “This clear shift in adhesive research opens new avenues and possibilities. I find it highly promising.”

Now that Bartlett says that he and his colleagues has shown that their cutting technique works for tailoring the adhesion of tapes and gloves, Bartlett says that the team plans to apply it to other systems. Those include robotic grippers and medical devices, such as extended wear glucose monitors. “There are a lot of possibilities,” he says.

–Sarah Wells

Sarah Wells is an independent science journalist based outside of Washington, DC.

References

- D. Hwang et al., “Metamaterial adhesives for programmable adhesion through reverse crack propagation,” Nat. Mater. (2023).