Winning Videos Feature Marbling Paint and Freezing Flashes

The APS Division of Fluid Dynamics has announced the 2023 winners of its annual Gallery of Fluid Motion video and poster contest. The videos below received the Milton van Dyke Award, which recognizes both videos and posters. A new traveling exhibit of past winners is currently on display at the National Academy of Sciences.

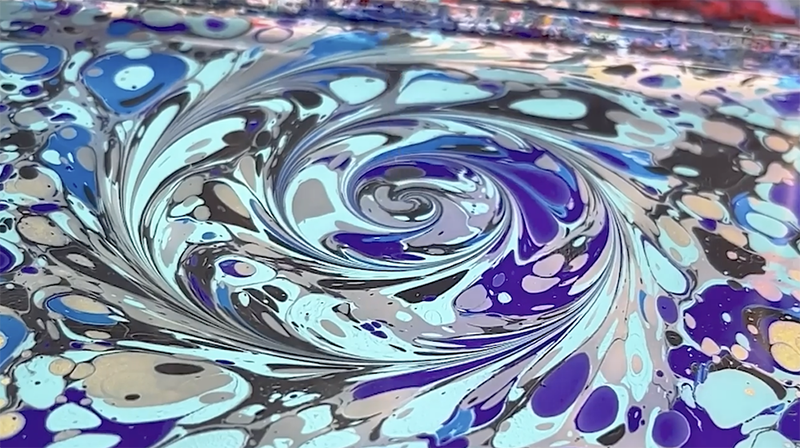

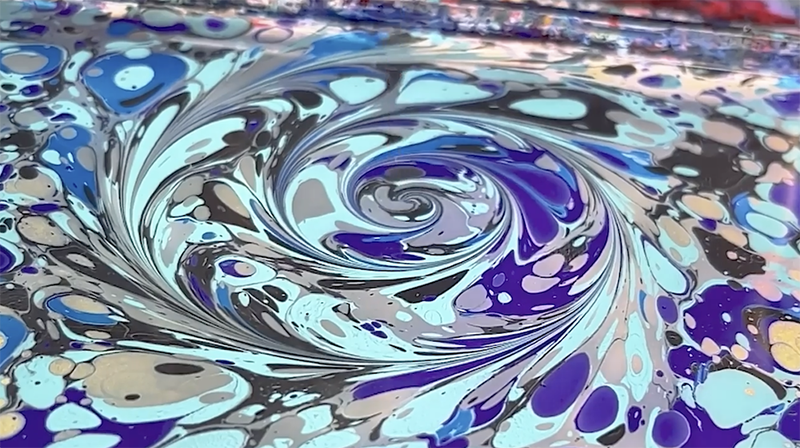

Ancient Art Provokes Hydrodynamics Questions

Marbling is an ancient art that involves dripping various paint colors on top of a viscous liquid surface, then disturbing the paint with tools, and finally laying paper on top to print the colorful patterns. In 2019, Harvard University applied-math graduate student Yue Sun became fascinated by both the hydrodynamics and the aesthetic appeal of marbling, so she learned how to do it. “One beauty of marbling is the randomness. You don’t really know what you’re going to end up with until you have it printed,” she says.

Sun and her colleagues have many questions about the fluid dynamics, but they address just two in their video: First, why does the paint float, even though it’s denser than the liquid bath below? According to the video, the fluids provide enough surface tension to prevent the paint from sinking. Second, why doesn’t the agitation and stirring of the colors cause them to mix together and create new colors? As the video explains, the bath beneath the paint is too viscous to mix from stirring, and paint diffusion across color boundaries is too slow.

Sun hopes to develop fluid dynamics simulations of marbling that are more accurate than those that currently exist. Her greater ambition, however, is to use math to improve her art. She recounts seeing beautiful marbling prints by other artists and wishing she could “reverse engineer” the patterns to learn what stirring strokes were used.

Fireworks from Condensed Water Droplets

A frost-covered window brings thoughts of a snowy day in mid-December, but the ice crystallization process may resemble a firecracker display on July 4th in the US. Graduate student David Paulovics of Côte d’Azur University in France and his colleagues captured new details of frost formation by observing a surface that was initially coated with liquid condensation—like fog on a bathroom mirror. The researchers abruptly reduced the temperature to about −20 °C and recorded the ensuing solidification with a high-end infrared camera. Paulovics recalls their surprise when the camera revealed a series of flashes coming from the chilled surface.

The team already knew that their protocol produces supercooled liquid droplets. Further investigation showed that when one of these droplets begins to crystallize, it releases a burst of latent heat that is observable in infrared light—a process called recalescence. The infrared flashes allowed the researchers to see that the freezing of droplets was not random—the flashes occurred in a ring-shaped region that propagated outward. This expansion implied that the freezing of one droplet induces freezing in its neighbors, like a cold virus spreading through a village. How was this crystallization being transmitted? Upon closer inspection, the team noticed small ice bridges connecting solid droplets to nearby liquid droplets (a phenomenon that others have observed). The team developed a model of this propagation, which may help engineers trying to mitigate the problems that frost can cause for airplane wings and wind turbines.

Lacy Material from a 3D Printer

A 3D printer produces a hot, continuous, toothpaste-like stream of plastic that solidifies into a straight, uniform thread when it cools. But the thread comes out differently when the print head moves faster than normal. “We find that rather than the thread just stretching thinner and thinner, it’s more energetically favorable for it to stick and stretch and stick and stretch,” says Princeton University graduate student Lauren Dreier. Her video shows how this stick-and-stretch process produces a periodic pattern of holes in the solidified plastic. This lace-like structure is not at all what the printer was designed to create, but she and her colleagues have found that the final material has unusual and potentially useful mechanical properties.

The material’s laciness reduces its weight and the amount of plastic required to cover a given area. The hole-filled structure can also give the material a stretchiness that varies with direction, a property similar to some textiles. This technique for making small and periodic holes without molds or complex machining could potentially be useful for fabricating shape-morphing mechanisms in soft robots or for creating shock-absorbing materials, says Pierre-Thomas Brun, Dreier’s PhD supervisor.

Dreier says that the slow-motion videos showing the periodic deposition of plastic blobs reminded her of the slow, walking-like tempo of the Andante movement of J. S. Bach’s Violin Sonata no. 2, which she chose to accompany her award-winning video.

–David Ehrenstein

David Ehrenstein is a Senior Editor for Physics Magazine.