Washing with Vortices

A porous material could be cleaned by subjecting it to pulses of liquid in the form of vortex rings—flow patterns that resemble smoke rings—according to Saptarshi Basu of the Indian Institute of Science, Bangalore, and his colleagues. As an early test of their idea, the researchers have now shown that such a vortex can effectively remove oil from a porous layer of beads and that since the vortex can penetrate the layer, it can clean both the front and back sides of the bead structure [1]. The results suggest that vortex rings have some advantages as a cleaning technique.

Pulses of vortex rings in air or water can be cheaper to generate than steady streams, and they provide rotational motion that could potentially be more effective for cleaning. In addition, if a vortex ring can clean both surfaces of a thin material, such as a filter in an industrial setting, the object might be cleaned in place without being removed. Basu and his colleagues are planning to build a “vortex gun” that mechanically generates high-energy vortex rings in air for removing dust.

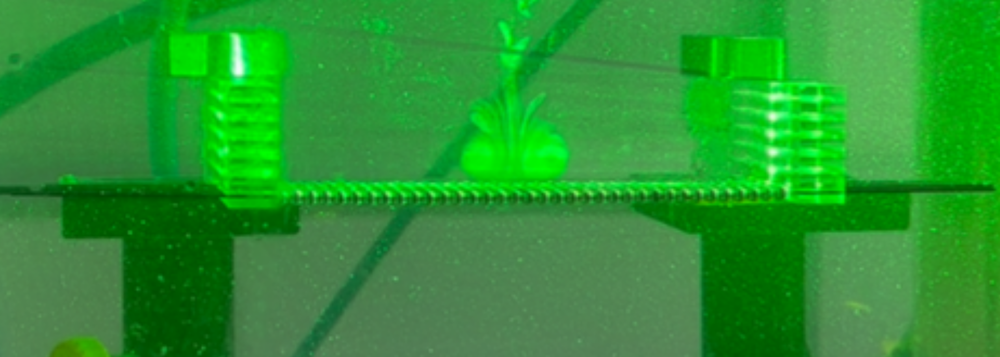

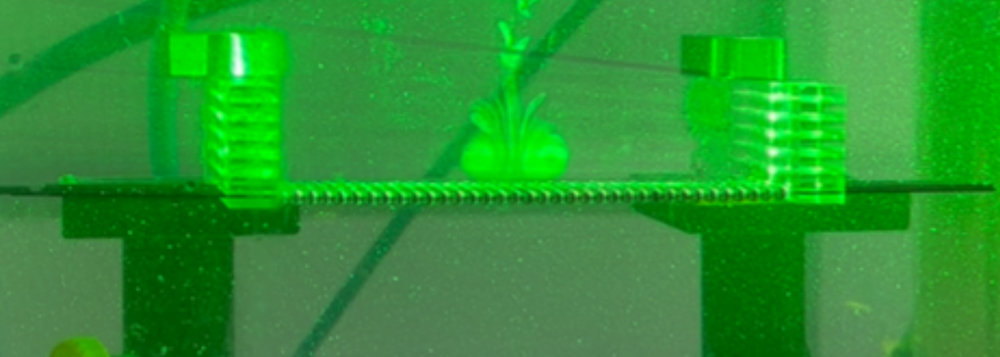

For their tests of the concept, the researchers placed an array of wire-strung beads under water and exposed it to vortex rings generated by injecting pulses of water through a 12-mm-wide pipe. They studied both clean and oily bead structures using several imaging techniques. The team noted a series of steps involved in the removal of the oil: first the vortex penetrates to the far side of the bead layer, then the oil extends from the structure as a series of tube-shaped films, and finally these tubes burst from being stretched as they fill with fluid from the vortex ring.

Basu and his colleagues concluded that the highest vortex rotation rates provided the most effective cleaning, but even at the lower rates, vortex rings could adequately clean the front surface. They also found that other factors could strongly affect the cleaning, such as the porosity of the bead structure.

–David Ehrenstein

David Ehrenstein is a Senior Editor for Physics Magazine.

References

- S. Jain et al., “Vortical cleaning of oil-impregnated porous surfaces,” Phys. Rev. Fluids 8, 044701 (2023).