How To Grow Silicon Carbide

Composed of a single layer of carbon atoms arranged in a honeycomb pattern, graphene exhibits desirable properties such as high mechanical toughness, high electrical conductivity, and high transparency. Theorists predict that a 2D layer of silicon and carbon atoms arranged in the same pattern, 2D silicon carbide (SiC), should also have high mechanical toughness. In addition, 2D SiC should easily absorb and emit photons, a wanted property for optoelectronics applications. However, experimentalists have struggled to make this material. Now Craig Polley of Lund University in Sweden and colleagues show that they can grow large-area 2D films of SiC using a sputtering-based technique [1].

Polley and colleagues started with a 360-µm-thick silicon carbide wafer. On that they sputtered a less-than-3-nm-thick film of another carbide material—either tantalum carbide or niobium carbide. The covered wafer was then annealed at 1700 ºC for 10 minutes.

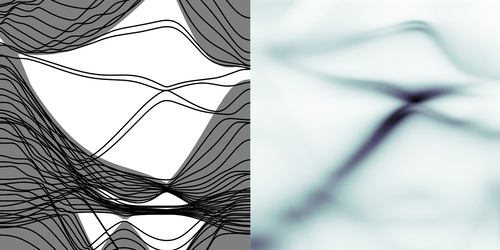

During the annealing process, the team found that that silicon and carbon atoms from the SiC wafer migrated to the surface of the carbide system and rearranged to form a single layer of honeycomb SiC. The group confirmed the presence of this 2D layer via spectral measurements. Tests of the layer show that it is stable at temperatures up to 1200 ºC under vacuum conditions.

Currently, the SiC cannot be “freed” from the underlying bulk material—it interacts strongly with the tantalum carbide or niobium carbide layer that it sits on. The team plans to investigate how to decouple the SiC from its substrate in the near future.

–Sophia Chen

Sophia Chen is a freelance science writer based in Columbus, Ohio.

References

- C. M. Polley et al., “Bottom-up growth of monolayer honeycomb SiC,” Phys. Rev. Lett. 130, 076203 (2023).