Bond Density Not Strength Controls Polymer Stickiness

No-drip paint and self-healing materials are made with polymers that contain “stickers”—chemical structures that form easy-to-break bonds. The currently favored theory for the behavior of such polymers assumes that it is controlled by the sticker bond strength. However, new experiments by Li-Heng Cai from the University of Virginia and his colleagues call that theory into question [1]. Instead, the team’s results indicate that sticker density is the key control knob for this system.

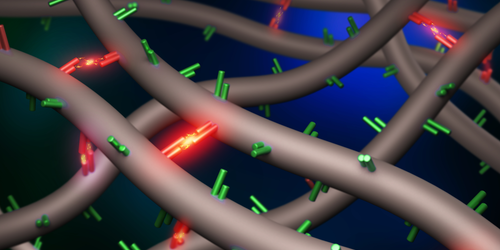

The way to make sticky polymers—also known as associative polymers—is to insert chemical links into the molecular chains that make up the polymer. These chemical stickers can form temporary attachments between chains, slowing the overall motion of the polymer. This friction-like effect has proved useful in controlling the viscosity of paints and fuels. Sticky polymers can also reform broken bonds—a self-healing feature that could benefit biomaterials used for tissue regeneration.

In their experiments, Cai and his colleagues synthesized polymers with up to eight stickers per polymer segment, in contrast with the typical one. The higher sticker densities resulted in polymers with more uniform stickiness. In x-ray imaging, the researchers found that the stickers interacted without collapsing into clusters—contradicting theoretical expectations. To explain this behavior, they devised a theory that considered polymer sticker density rather than the previously used bond strength. Cai says that their observations and modeling could guide further development of associative polymers.

–Michael Schirber

Michael Schirber is a Corresponding Editor for Physics Magazine based in Lyon, France.

References

- S. Nian et al., “Dynamics of associative polymers with high density of reversible bonds,” Phys. Rev. Lett. 130, 228101 (2023).