Liquid Iron Measured under the Most Extreme Conditions Yet

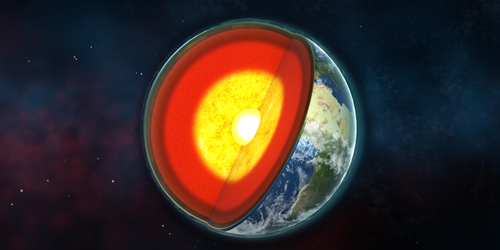

The cores of Mercury, Venus, Earth, and Mars are largely made from iron. Scientists have studied iron’s properties, such as its electrical resistivity, under high temperatures and pressures. But the measurements have largely been on solid iron, not liquid iron, which most of these rocky planets’ cores are thought to contain. Now Kenji Ohta of the Tokyo Institute of Technology and his colleagues have measured the electrical resistivity of liquid iron at a higher pressure than previously achieved [1]. The results could help scientists better understand the growth of planetary cores.

Electrical resistivity measurements of liquid metals are tricky, as the material must maintain its shape throughout the measurements for researchers to get a true value, something that liquids tend not to do. Ohta and his colleagues developed two new methods to measure the electrical resistivity of their samples. In the first, they encapsulated the iron inside single-crystal sapphire before subjecting it to high temperatures and pressures. The encapsulation maintained the sample’s shape throughout the experiment. In the second, they used a standard high-pressure technique—a diamond-anvil cell. They took measurements within a few milliseconds of the sample reaching the target conditions, before it could deform. By combining these techniques, the team was able to measure the electrical resistivity of liquid iron at pressures 2 times greater than those previously achieved.

The motion of iron in the core of a planet is responsible for its magnetic field. Geophysicists use electrical resistivity measurements to probe the generation mechanism of planetary magnetic fields and the evolution of planetary cores. Our results provide “fundamental information” for such studies, Ohta says.

–Katherine Wright

Katherine Wright is the Deputy Editor of Physics Magazine.

References

- K. Ohta et al., “Measuring the electrical resistivity of liquid iron to 1.4 Mbar,” Phys. Rev. Lett. 130, 266301 (2023).