Meetings: Physics Gets in Touch with Its “Softer” Side

Nearly 700 scientists from 37 countries met in Grenoble, France for this year’s International Soft Matter Conference. The talks covered myriad topics, including organ “bandages” that halt blood flow during surgery and advances in advances in fabricating 3D nanostructures. Here are three stories that capture the diversity of research reported at the meeting.

–Katherine Wright

10000-Hour Foams

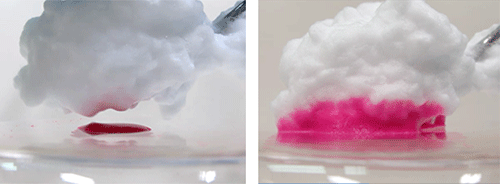

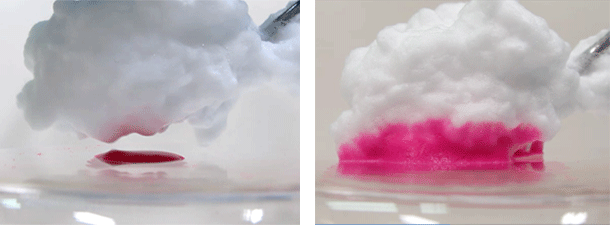

Pour bubble bath under running water and it forms a mountainous white froth. But within seconds, this fragile foam starts to disappear as gravity drains the liquid trapped between the bubbles, and they pop. The short lifetime of foams doesn’t just put an abrupt end to a relaxing bath, it also limits the use of foams for a promising application: cleaning up chemical leaks or nuclear waste-water. Fortunately, Cécile Monteux from ESPCI Paris-Tech has created long-lived stable foams that could be used to mop up such spills.

Monteux makes the foams from a polymer liquid that she rapidly stirs with a kitchen mixer to incorporate air bubbles. The polymer liquid has a higher viscosity than water, allowing it to stay foamed for a few hours. By mixing in borax, a chemical that bonds the polymer chains to one another, Monteux increases the foam’s lifetime to over ten thousand hours—long enough to transport the foam to wherever it’s needed. Moreover, she finds that adding borax improves the foam’s retention of fluids, a plus for cleaning up spills. Foams are natural absorbers of liquid because the channels between the bubbles act as capillaries that create a suction effect. Incoming fluid tends to break down these channels, as it dilutes the polymer holding the foam together. But with borax present, the foam remains rigid, keeping an “invading” fluid trapped for hours. The contaminated foam can then be moved elsewhere and its liquid safely disposed.

Read more in this paper from Soft Matter.

Powering Gears with Light

With micromachines, scientists might one day build miniature robots that tackle the stuff of science fiction—fighting diseases inside living cells or manufacturing materials atom-by-atom. Light could, in principle, provide a reliable and continuous source of power to move these machines, but its effects are generally too weak: A 1-milliwatt laser, for example, imparts just 1 piconewton of force to a micrometer-sized object, barely enough to get it to twitch. Claudio Maggi and colleagues in Roberto Di Leonardo's team at the Sapienza University of Rome have developed a method that uses low-powered light from a light-emitting diode (LED) to make a floating microgear twirl. Their approach entails inducing temperature gradients in the fluid surrounding the gear and achieves rotation speeds of up to 300 rpm (see video).

The researchers worked with a gear shaped like a star with slanted arms. The gear heats up when it’s illuminated by the LED, transferring some of its heat to the surrounding liquid. This causes a localized decrease in the liquid’s surface tension. Because the gear’s arms are slanted, the surface tension is greater on one side of each tooth than the other, and the gear turns. With just a 5-milliwatt LED, Maggi’s team was able to spin the gear. And by changing the intensity of the incident light, they could vary the gear’s rotational speed.

Read more in this paper from Nature Communications.

Materials that Copy Nature

Natural materials have complex structures that are perfectly honed for a specific function. Consider teeth. Externally they have intricate curves, grooves, and roots; internally each layer of enamel and dentin consists of aligned particles, but the particular alignment varies from layer to layer. This combination of order and heterogeneity helps teeth cut and resist cracking. André Studart and his team from the Swiss Federal Institute of Technology (ETH), Zurich, have now developed a way to recreate teeth and other functional materials that mimic nature’s similarly intricate designs. Unlike many existing techniques, which require multiple tools and processing steps, Studart’s approach produces elaborately shaped composites with one continuous process.

Studart’s method utilizes a liquid consisting of a suspension of magnetically responsive, disk-shaped particles. He first pours the suspension into a dry porous mold whose pores allow liquid, but not particles, to pass through. As the liquid seeps out, the particles accumulate layer-by-layer at the mold’s surface; Studart then controls the particles’ orientations with a magnetic field. Once dry, the ordered particles can be infiltrated with other materials—polymers, metals, and ceramics—to create bulk composites with periodic microstructures and tunable properties. Using his technique, Studart has fabricated full-size teeth, successfully replicating their shape and structure.

Read more in this paper from Nature Materials.