Stretching More with Pores

Devices ranging from sonar to precision valves use materials that change shape when exposed to a magnetic field. Now a team reports in the 14 December Physical Review Letters that it has developed a new material with a shape-change effect as large as any commercial material but potentially cheaper and lighter than others. They created a porous foam of an alloy that was previously known but not very effective. The porous form amplifies the shape-change effect, so the researchers believe it could be used in tiny motion control devices or pumps without mechanical parts.

A nickel-manganese-gallium (Ni-Mn-Ga) sample contracts in the direction of an applied magnetic field and expands in a perpendicular direction. When the field is turned off, the sample retains its new shape but will regain its original shape if the field is rotated 90 degrees. First observed in 1996, this so-called magnetic shape memory comes from a magnetically sensitive atomic structure.

Imagine a two-dimensional crystal lattice made of parallelograms all “leaning” to the left, but above a certain horizontal line–called a twin boundary–the parallelograms all lean to the right. This alternate leaning may repeat, with several layers of “twins” above the first pair, forming a zigzag pattern. Each parallelogram has a magnetic moment, like a tiny bar magnet, pointing parallel to the tilted sides. A magnetic field aligned with the right-leaning parallelograms switches the left-leaning ones into right-leaning and straightens out the zigzags, which lengthens the crystal along the new direction of alignment.

The twin flipping allows Ni-Mn-Ga crystals to elongate by 10 percent, the biggest magnetically-induced deformation–or “strain”–of any material. But making large single crystals is a slow, expensive process, and it isn’t commercially viable. It’s easier to make so-called polycrystalline alloys, which contain many small, randomly oriented crystals, or “grains,” but boundaries between differently-oriented crystals restrict the twin motion, leading to very small strains.

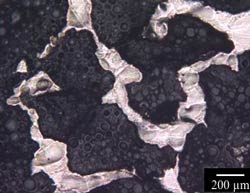

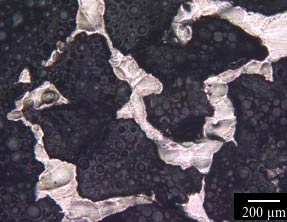

David Dunand of Northwestern University in Evanston, Illinois, Peter Müllner of Boise State University in Idaho, and their colleagues have now increased the strain in polycrystalline Ni-Mn-Ga by nearly fifty times by introducing pores. The team poured molten Ni-Mn-Ga into a chunk of porous sodium aluminate salt, and after cooling, they leached out the salt with acid. They took samples of the “foam” left behind and exposed them to a 1-Tesla magnetic field that rotated at 12,000 revolutions per minute, while a laser system measured the induced strain. The team found the highest strain in their most porous sample (76 percent empty space), which deformed by as much as 0.12 percent in the rotating field.

The researchers attribute the improvement to the greater freedom for twin reorientation inside the foam, whose microstructure is an interconnected network of thin struts, each surrounded by empty space. “The struts become almost like single crystals,” Dunand says.

Although the foam strain is 100 times less than that of Ni-Mn-Ga single crystals, the strain and millisecond response time are comparable to that of Terfenol D, whose magnetically-controlled vibration gives the ping in Navy sonar equipment and is used in audio devices. Terfenol D–which changes shape by a different microscopic process–is an expensive material, so the team believes the foam could one day be a cheaper, lightweight alternative. The porous structure could also work as a tiny biomedical pump that could squish fluid through it without the need for moving parts.

Vladimir Chernenko, of the Institute for Energetics and Interfaces in Lecco, Italy, believes this technological achievement–the first foam to exhibit magnetic shape memory–has great potential. “With further improvement of architecture, the performance can be increased,” Chernenko says. The authors will need to verify other mechanical properties of their material, but he thinks its large strain and small weight might make it useful for space-born applications.

–Michael Schirber

Michael Schirber is a Corresponding Editor for Physics Magazine based in Lyon, France.

More Information

explanation of magnetic shape memory in Ni-Mn-Ga from the Helsinki University of Technology