Squirting Water without a Gun

Fluid jets are normally made by forcing liquid through a nozzle, such as in a squirt gun or a syringe. But in the 10 July Physical Review Letters, researchers report a way to induce a fluid jet to burst from an isolated droplet. The team placed a liquid droplet on a surface and blasted it with focused surface acoustic waves–nano-sized versions of the ground-shaking waves from earthquakes–causing the droplet to shoot upward in a narrow stream. The researchers believe the technique could be useful in drug delivery, biomedical research, and inkjet printing.

One of the challenges in microfluidics, the manipulation of small amounts of fluid, is in propelling liquid. Because of high surface tension, pumping fluid through micron-scale channels requires considerable effort–like drinking a milkshake through a narrow straw. Many microfluidic devices, which are often as small as a credit card, must be attached to a big pump, resulting in an unwieldy and inefficient arrangement.

To overcome this problem, researchers led by Leslie Yeo of Monash University in Australia are turning to surface acoustic waves (SAWs). SAWs are tiny versions of the seismic surface waves (Rayleigh waves) from earthquakes (see animations here). SAW amplitudes can be just a few nanometers, and they have traditionally been used in telecommunications and in touch-screen technology, among other areas. Only in recent years have they been used to manipulate liquids, says Yeo, for vibrating and breaking up droplets, for example. Now he and his colleagues have used SAWs to generate fluid jets.

The researchers put two electrodes on a lithium-niobate piezoelectric surface, a material that converts electric voltage into SAWs. The electrodes, made from arrays of curved metal strips, or arcs, took up two 90-degree sectors of a disk shape, with a hole in the center. The arrays focused SAWs from opposite directions into the center, where the researchers placed a 1- to 5-microliter drop of water, ethanol, methanol, or octanol.

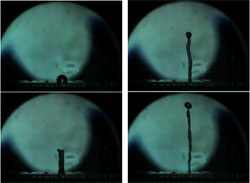

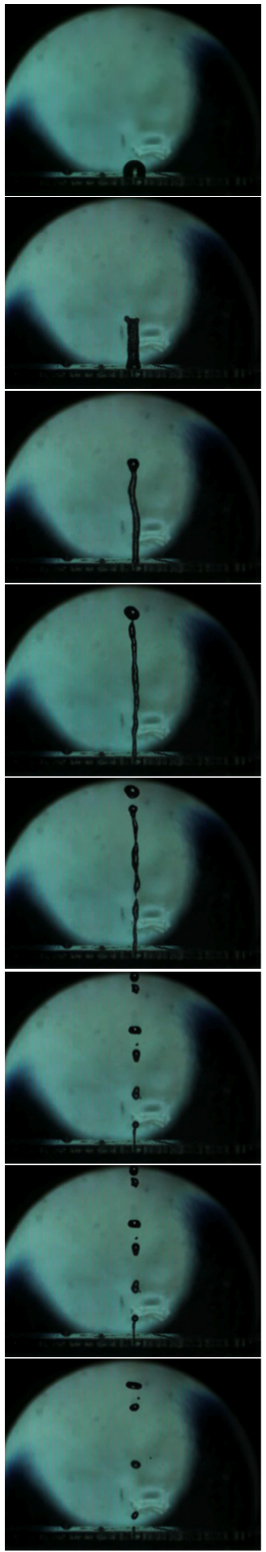

The vibrations, at a frequency of 30 megahertz, triggered different behaviors in the droplets, depending on the vertical acceleration of the waves, which the team controlled with slight changes in their amplitude. For smaller amplitudes, the force wasn’t strong enough to overcome the droplet’s surface tension, so it merely oscillated in place, sloshing between a flattened shape and a “mountain” shape, like a Hershey’s chocolate kiss. For larger amplitude SAWs, the mountain erupted into a jet 1 to 2 centimeters high, reaching speeds of several meters per second. The larger the SAW amplitude, the longer the jet. At even higher amplitudes, the jet broke up into a series of smaller droplets. The largest SAWs caused the droplet to explode in a flurry of even tinier droplets, a process called atomization.

The next step, Yeo says, is to develop more precise ways to control the jets for future applications. For example, small devices could employ jets to efficiently deliver accurate doses of drugs. The miniaturization made possible by SAW-induced jets could also result in smaller and more efficient DNA microarrays, which are used to analyze thousands of genes at once in the study of diseases. Another application is inkjet printers, which now rely on nozzles to shoot tiny drops of ink onto paper.

This work is an “interesting approach to manipulating fluids on small scales that hasn’t seen a lot of investigation in the past,” says Michael Graham of the University of Wisconsin in Madison. In addition to showing more jet control, he says, future studies should consider droplets at smaller scales, where viscosity becomes more important.

–Marcus Woo

Marcus Woo is a freelance science writer in the San Francisco Bay Area.

More Information

more video of microjets, with musical sound track

more videos of SAW micro/nanofluidics (Yeo and Friend, Micro/Nanophysics Research Lab, Monash University)

more on SAW microfluidics (L. Yeo, Monash University)

animations comparing water waves with Rayleigh waves (Dan Russell, Kettering University)