Short Pulses Know the Drill

Femtosecond (fs) laser pulses can cut solids much more precisely than other lasers—a property that makes them useful for micromachining. This is because the pulses are so short that they vaporize materials before they melt. An important application would be the patterning of thin films into devices like waveguides, Bragg gratings, or photonic crystals. But micromachining thin films has proven challenging: ablation often has the unwanted effect of damaging the surface of the substrate on which the films are deposited, and laser fluctuations limit the reproducibility of the features drilled in such thin structures. As reported in Physical Review Applied, Laurent Mercadier and colleagues at the Joint University of Ottawa and National Research Council Laboratory for Attosecond Science have demonstrated a reliable scheme to pattern small holes in a thin polymer film with fs lasers.

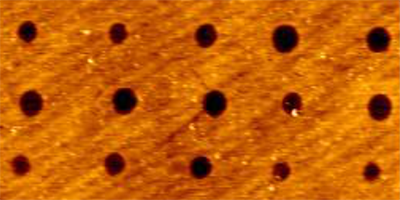

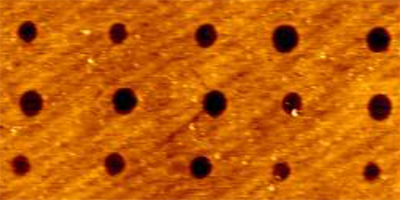

The authors’ idea is to exploit the supporting dielectric substrate to “tame” the pump laser pulses, making them more suitable for ablation. The 45-fs incoming pulses are first made to propagate through the substrate. There, thanks to the combination of nonlinear effects and absorption, two phenomena occur. First, the pulse intensity saturates to a maximum value, reducing laser fluctuations. Second, the beam’s spatial profile becomes independent of the input energy. These reshaped, better-behaved pulses then impinge on the thin films on the opposite side of the substrate. The experiments reveal that the pulses, even in the presence of large input-energy fluctuations, drill holes in a reproducible way without damaging the substrate surface. The holes’ sizes are constant over a broad range of laser energies and can be defined with a precision finer than the laser wavelength. – Matteo Rini