Unifying Liquid and Granular Flow

Adding suspended particles to a fluid increases its viscosity. When the particles are widely separated, this increased viscosity reflects their hydrodynamic interactions. At higher volume fractions, however, contacts between particles become important, and eventually jamming occurs and the viscosity diverges. While this phenomenology is known, there is no general theory that predicts how the viscosity depends on volume fraction, particularly when both hydrodynamics and collisions are significant [1]. In a paper in Physical Review Letters [2], François Boyer and colleagues from Aix-Marseille University in France study suspensions using a framework previously used to describe the flow of dry granular materials, in which particles interact solely through contacts. In addition to unifying our understanding of the flow behavior (rheology) of two quite different systems, the work of Boyer et al. provides important new perspectives on both the jamming transition [3] and the rheology of suspensions such as mud, paints, and medicines.

Fluid flow is described by the continuum Navier-Stokes equations, supplemented by boundary conditions and a constitutive relation between the shear stress τ in the fluid and the strain rate ·γ. In the simplest, Newtonian, case, τ is proportional to ·γ; the constant of proportionality is the viscosity η. Few real fluids are Newtonian, however, and it is difficult to derive constitutive relations for more complex fluids. For suspensions, Einstein calculated the increase in viscosity over that of the background fluid to first order in the volume fraction, φ [4], and hydrodynamic interactions between particles lead to an additional, second-order contribution proportional to φ2 [5]. The resulting expression for η(φ) works well at low-to-medium volume fractions, but fails when φ is high enough that contact interactions become important [1].

Boyer et al. [2] approach the problem from a different direction, starting from the flow of dry granular materials [6,7]. Granular flows are similar to flowing liquids in many ways, for example, they can exhibit similar flow instabilities [8]. They differ in other respects, though. Flows in granular media are governed by dissipative interparticle collisions and friction between contacting particles rather than by viscosity. Granular systems cannot always be treated as continua on the scale of the flow, and thermal fluctuations are negligible because the particle size is macroscopic.

There is no general equation of motion that describes granular flows, and until recently there were few indications of any sort of universality among different systems. In 2004, however, a paper authored by the French research collective GDR MiDi—the Groupement de Recherche sur les Milieux Divisés—compared flows in several granular systems [9], and identified common behavior in some of them. They also used dimensional analysis to develop a model for granular rheology: For rigid spheres in a system large enough that boundaries have no influence, the parameters that describe the flow are the shear rate ·γ, the pressure P, the size of the grains d, and their density ρ. The only dimensionless combination of these parameters is the inertial number I=·γd/√P/ρ. This can be interpreted as the ratio of d/√P/ρ, the time scale for particles to rearrange due to the pressure P, to the time scale ·γ-1 for deformation by the flow. It follows that both the dimensionless stress τ/P and the volume fraction φ must be functions of I alone. That is,

where μ is an effective friction coefficient, while

is considered to vary in response to the flow conditions. These equations are the constitutive laws. GDR MiDi found that this approach was indeed applicable to some systems, notably dense granular flows down an incline, because both μ and φ collapsed onto universal curves when plotted as functions of I.

Cassar et al. [10] studied dense granular flows down an underwater incline. In this case, the viscous interaction between the interstitial water and the grains changes the time scale for particle rearrangements, so they replaced I by the ratio of this modified rearrangement time to the reciprocal shear rate. Even though the grains moved much slower in water than in air, Cassar et al. found that the friction coefficient μ, determined from experiments using different grain sizes in both air and water, collapsed onto a single curve, as long as the corresponding ratio of time scales was used.

In the new paper [2], Boyer et al. apply the same ideas to suspensions with a range of volume fractions. If viscous forces dominate, then the time scale for particle rearrangements is ηf/P, where ηf is the viscosity of the background fluid. The ratio of this viscous time to the time scale of the flow is Iν=ηf·γ/P, referred to as the viscous number.

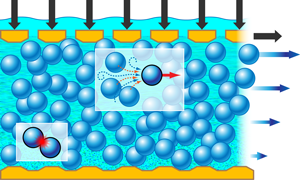

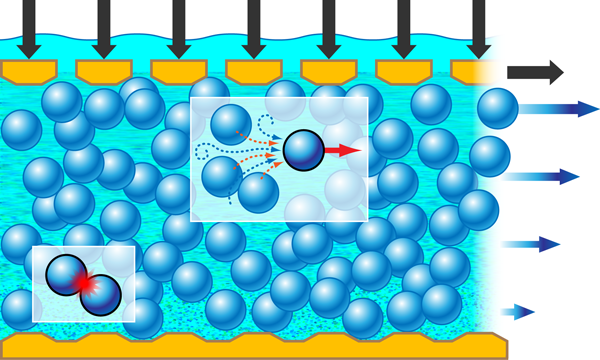

In clever experiments, the researchers confine a suspension between a fixed lower surface and a porous, planar top plate in an annular shear cell. A controlled torque is applied to the top plate, shearing the suspension at a measured rate ·γ (see Fig. 1).They also control the pressure P through the vertical force applied to the top plate, whose height can adjust in response to dilation or compaction of the sheared suspension. This allows them to determine both the effective friction coefficient μ and the volume fraction φ of the suspension as functions of Iν. From experiments on suspensions with different background fluid viscosities and different sizes of suspended particles, they find that μ(Iν) and φ(Iν) once again collapse onto universal curves. φ has a maximum at Iν=0, corresponding to the jamming transition at which the suspension viscosity becomes infinite and flow ceases.

Boyer et al. go on to show that their formulation in terms of the friction coefficient μ is equivalent to the more conventional treatment using an effective shear viscosity ηs. They calculate ηs from their data and show that when plotted as a function of φ, it diverges as a power law, (φm-φ)-2, near the critical value φm for the jamming transition.

Finally, Boyer et al. propose expressions for the constitutive laws μ(Iν) and φ(Iν) based on their results. Their expression for μ includes two terms: one due to viscosity, and one due to collisions. The viscous term is constructed to reduce to Einstein’s expression for the suspension viscosity at low volume fraction, while the form of the collision term shows the observed power-law divergence at the jamming transition. These semiempirical expressions describe their data very well over the range of volume fractions studied.

The results of Boyer et al. are significant for a number of reasons. First, they show that describing flow in terms of an effective friction coefficient works for both granular flows and suspensions, even though the interactions between the particles are quite different in the two cases. Second, this new way of looking at suspension rheology could prove useful in the difficult range of φ, where both hydrodynamics and collisions are important. Finally, their results for the scaling of the effective shear viscosity near the jamming transition suggest that their method will be useful for studying jamming in other systems as well. There remain open issues, however. In particular, not all granular flows are completely described by the inertial number I, so the generality of this approach remains uncertain, and it remains a challenge to calculate the parameters of this model theoretically.

References

- J. J. Stickel and R. L. Powell, Annu. Rev. Fluid Mech. 37, 129 (2005)

- F. Boyer, É. Guazzelli, and O. Pouliquen, Phys. Rev. Lett. 107, 188301 (2011)

- A. J. Liu and S. R. Nagel, Nature 396, 21 (1998)

- A. Einstein, Investigations on the theory of the Brownian movement (Dover, New York, 1956)[Amazon][WorldCat]

- G. K. Batchelor, J. Fluid Mech. 83, 97 (1977)

- H. M. Jaeger, S. R. Nagel, and R. P. Behringer, Rev. Mod. Phys. 68, 1259 (1996)

- Y. Forterre and O. Pouliquen, Annu. Rev. Fluid Mech. 40, 1 (2008)

- I. S. Aranson and L. S. Tsimring, Rev. Mod. Phys. 78, 641 (2006)

- GDR MiDi, Eur. Phys. J. E 14, 341 (2004)

- C. Cassar, M. Nicolas, and O. Pouliquen, Phys. Fluids 17, 103301 (2005)