Measuring the Forces in a Knot

Knots have such sharp twists and turns that researchers have had trouble determining precisely how a knot's shape affects the forces within it. But now a team has theoretically modeled a simplified knot, showing the effects on the internal forces when adding or subtracting a turn. The theoretical calculations matched the team's experiments in which thin metal wires were tied into large open knots. The results may guide future work in characterizing more complicated knots that are pulled small and tight.

Knots are defined by their configuration, or what mathematicians call topology. A seemingly small change in the tying procedure can produce an entirely different knot with radically different mechanical properties. For example, a common shoelace-tying mistake leads to the less-secure "granny knot." The importance of topology seems obvious to anyone who has created a "slip knot," but mathematical models have yet to predict exactly how a knot's performance will depend on topology. Part of the difficulty is that the sharp twists and turns generate forces that are difficult to calculate, even with computer simulations.

To avoid sharp turns, theoretical work has focused on simple cases such as a rope wrapped several times around a post, which can lock the rope in place with friction but isn't a true knot. Basile Audoly from the Sorbonne Universities in Paris, Pedro Reis of the Massachusetts Institute of Technology in Cambridge, and their colleagues realized that if you tie a knot out of wire, it remains open and free of sharp turns, thanks to the strong bending stiffness of the material. This structure is also of interest because many knots are made with stiff materials like surgical thread or protein molecules.

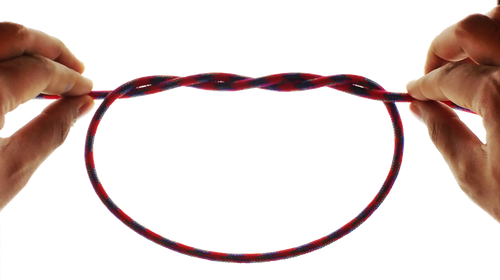

The team decided to study overhand knots, the simplest of which is the trefoil knot, made by forming a loop in the middle of a rope and then passing one end of the rope through the loop. You can make more complicated overhand knots (such as a double overhand knot) by passing the rope through the loop multiple times. The number of passes (n) defines the topology of the knot.

For the experiments, the researchers formed overhand knots with n values from 1 to 10 using nickel-titanium wires. In each case, they applied tension to the two wire ends, so that the loop began to close. However, the bending stiffness of the wire caused the knot to “lock” with the loop still open. The shape of this open knot is set by the bending stiffness of the material and by friction in the "braid," where the two ends of wire twist around each other n times.

In previous work [1], Audoly and others calculated the shapes and forces produced in the two simplest overhand knots (n = 1 and n = 2). In these cases, the braid is short and friction can largely be neglected. However, the new experiments showed that these earlier calculations could not be extended to knots with higher n values. The researchers discovered that, as n increases, the loop becomes dramatically harder to close. Audoly and his colleagues found a way to solve the more difficult problem of large n knots by treating the braid and loop separately.

The researchers first modeled the braid as a helix whose pitch (twist steepness) is closely related to the friction. The tighter the helix, the greater the friction. The loop, on the other hand, resembles a classic mechanics problem of an elastic rod being bent while holding one end fixed. The team took the well-known solution to this problem and combined it with their helix model. The result was a single mathematical relation between the topology (n) and the mechanical variables—friction, bending stiffness, and tension. Audoly admits that this formula does not apply to everyday rope knots that are pulled tight. But he sees it as “a starting point” for attacking these more complicated problems with computer simulations.

Chris Santangelo from the University of Massachusetts, Amherst, is amazed that the authors were able to characterize the frictional forces in a knot in terms of its configuration. “I think it opens up an interesting area between topology and mechanics,” Santangelo says.

This research is published in Physical Review Letters

–Michael Schirber

Michael Schirber is a Corresponding Editor for Physics Magazine based in Lyon, France.

References

- B. Audoly, N. Clauvelin, and S. Neukirch, “Elastic Knots,” Phys. Rev. Lett. 99, 164301 (2007).