Nanotubes Go with the Flow

Researchers have assembled carbon nanotubes into arrays of loops, lassos, and hooks, according to the 13 February PRL. Physicists hope to use these several-nanometer-diameter tubes to build tiny mechanical and electronic devices, and the unexpected bending shows that they are more versatile than had been assumed. As one example, these bent tubes might lead to more sensitive sensors to detect fluid flow.

The slenderness and electrical conductivity of carbon nanotubes, which resemble all-carbon rolls of chicken wire at the atomic scale, make them enticing candidates for nano-sized sensors or circuits. In attempting to construct arrays of nanotubes, researchers usually treat them as so many pickup sticks or pieces of dry spaghetti. But Vladimir Tsukruk and his colleagues at Iowa State University in Ames found that weak forces can bend nanotubes quite easily. The team was in the midst of experiments aimed at another problem: aligning a large group of nanotubes into a desired orientation. Some groups have made nanotubes point the same way by gently dipping a nanotube-covered surface into water, aligning the tubes with the fluid flow, like wheat stalks blown in a wheat field.

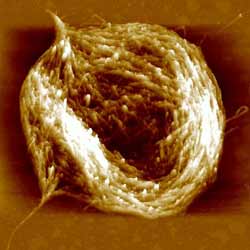

Tsukruk and his colleagues wanted to make stripes of aligned nanotubes–alternating with blank stripes–on the surface of a silicon wafer. They first used a variation on a standard technique to create stripes of randomly oriented tubes. The surprise came when they dipped their sample in water and dried it slowly: up to 40% of the tubes came out bent like a “U”, rather than straight. And the U-shapes were aligned. By adjusting the rate of withdrawal, rinsing, and drying, they could make the molecules bend back onto themselves like needle eyes, nooses, or even nest-like coils.

The researchers hypothesize that the surface tension of evaporating water droplets drives the bending. Droplets cling to the wafer after dipping in water. Some of these happen to rest on top of a nanotube. Surface tension makes the tube cling to the droplet and follow its shape. As it evaporates and shrinks, the tube curls with it. Differences in the size and location of the droplets lead to different shapes.

“We thought of nanotubes as these rod-like structures,” says Tsukruk. “What we demonstrated [is that] even very weak fluidic forces can bend them and make different shapes.” For that same reason, arrays of bent nanotubes should be able to detect fluidic flow, he says. Additional bending would increase the strain on the nanotubes and change their optical properties. The group is currently studying how to probe such changes by observing the spectrum of light sent through the nanotubes.

The somewhat controlled bending is novel and may alter the tubes’ electronic properties suitably for designing sensors and field emitters, says Yury Gogotsi of Drexel University in Philadelphia. He says they have to achieve better control over the orientation of the nanotubes before they can think about devices, though. “It might make a better sensor, but you still need an address system for [each] bent tube,” which requires more control of individual nanotubes than researchers have yet achieved, says James Tour of Rice University in Houston. But he says they might get around imprecise control over bending by first creating an array of bent tubes, and then calibrating the sensor.

–JR Minkel

JR Minkel is a freelance science writer in New York City.

More Information

“The Nanotube Site” at Michigan State University gives a comprehensive list of nanotube-related links.

Another team has used fluid flow to orient nanotubes in complex patterns, though the tubes remain stiff: “Nematic Liquid Crystallinity of Multiwall Carbon Nanotubes,” W. Song, I. A. Kinloch, and A. H. Windle, Science 302, 1363 (2003)